Motor case

A technology of motor casing and casing, which is applied in the directions of casing/cover/support, electrical components, electromechanical devices, etc., can solve the problems of easy falling off of the bracket, high production cost, complicated process, etc., and improve market competitiveness. , the effect of saving materials and reducing safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below through specific embodiments and in conjunction with the accompanying drawings.

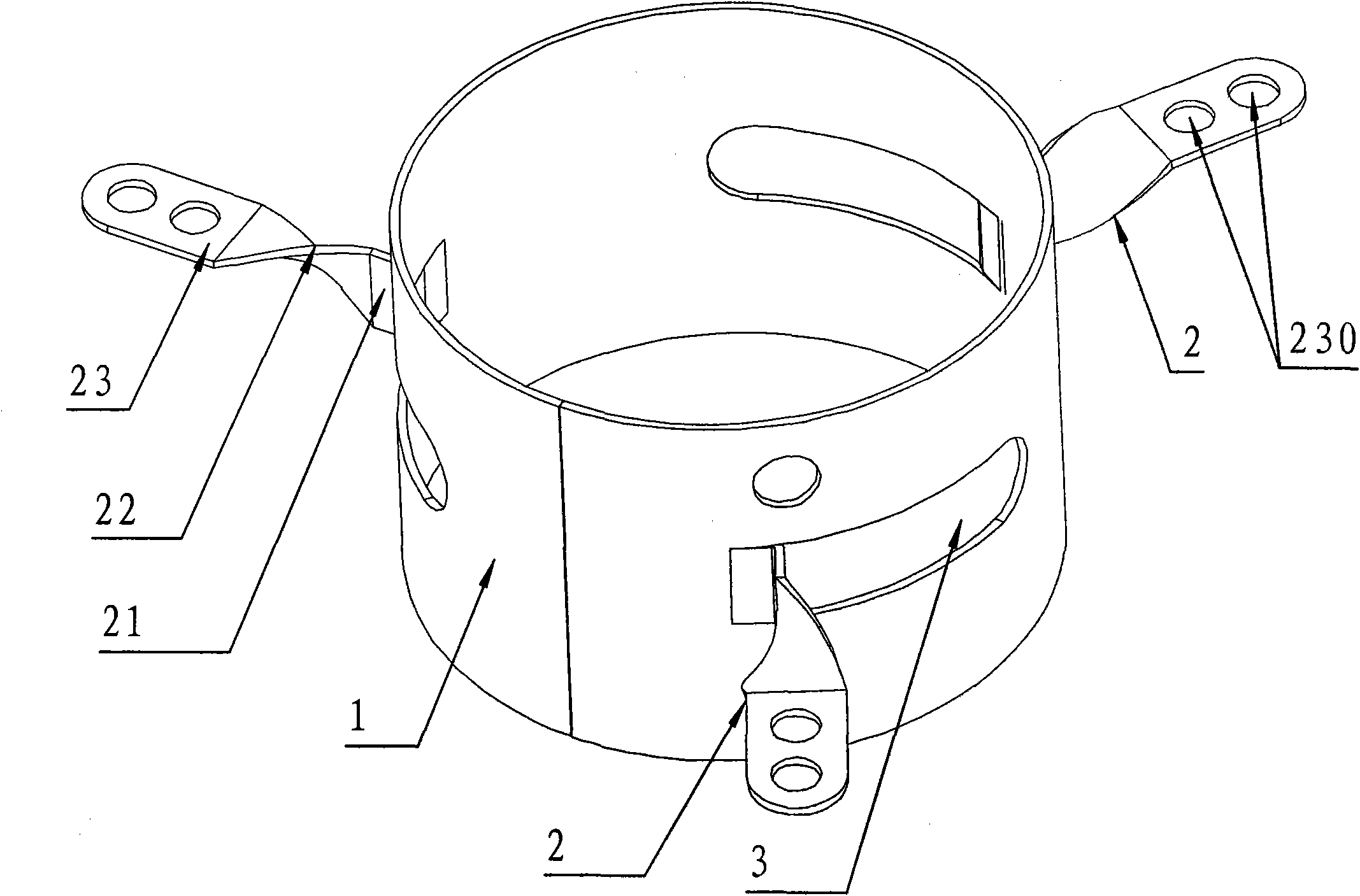

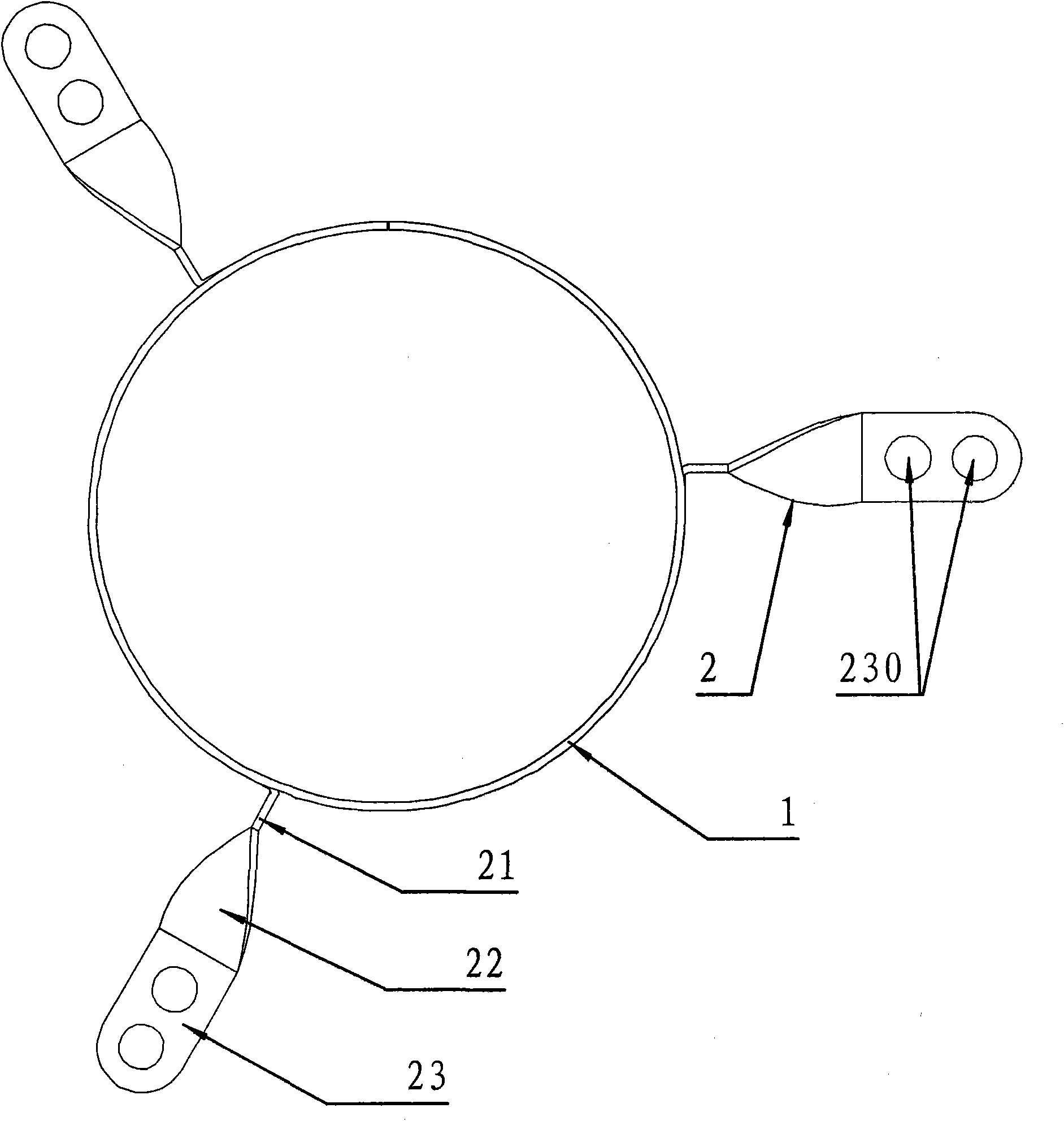

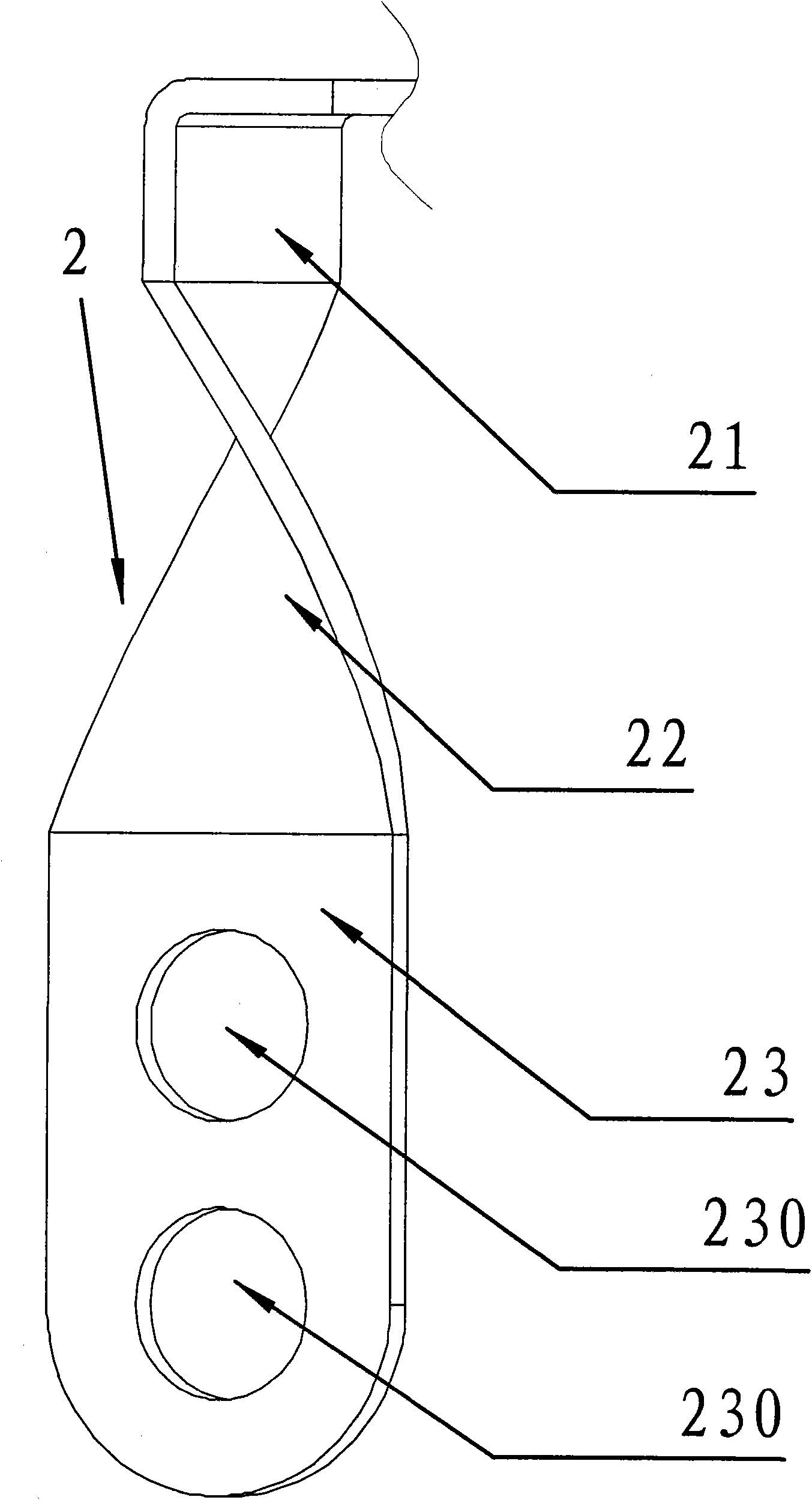

[0018] like figure 1 , figure 2 and image 3 As shown, a motor casing of the present invention includes a hollow motor casing 1, and several brackets 2 are stamped out on the wall surface of the motor casing 1, and are formed beside the bracket 2 and on the wall surface of the motor casing 1. Groove 3, one end of bracket 2 is also connected to the wall surface of housing 1; bracket 2 includes fixing part 21, intermediate connecting part 22 and installation part 23, one end of fixing part 21 is connected with motor housing 1, and the other end It is connected with the intermediate connecting part 22, and the outer end of the intermediate connecting part 22 is connected to the mounting part 23; the intermediate connecting part 22 is twisted; several brackets 2 are located on the same section of the wall surface of the motor h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com