Nondestructive inspection ultrasonic probe universal joint pallet

An ultrasonic probe, non-destructive testing technology, used in material analysis, measuring devices, instruments, etc. using sonic/ultrasonic/infrasonic waves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings.

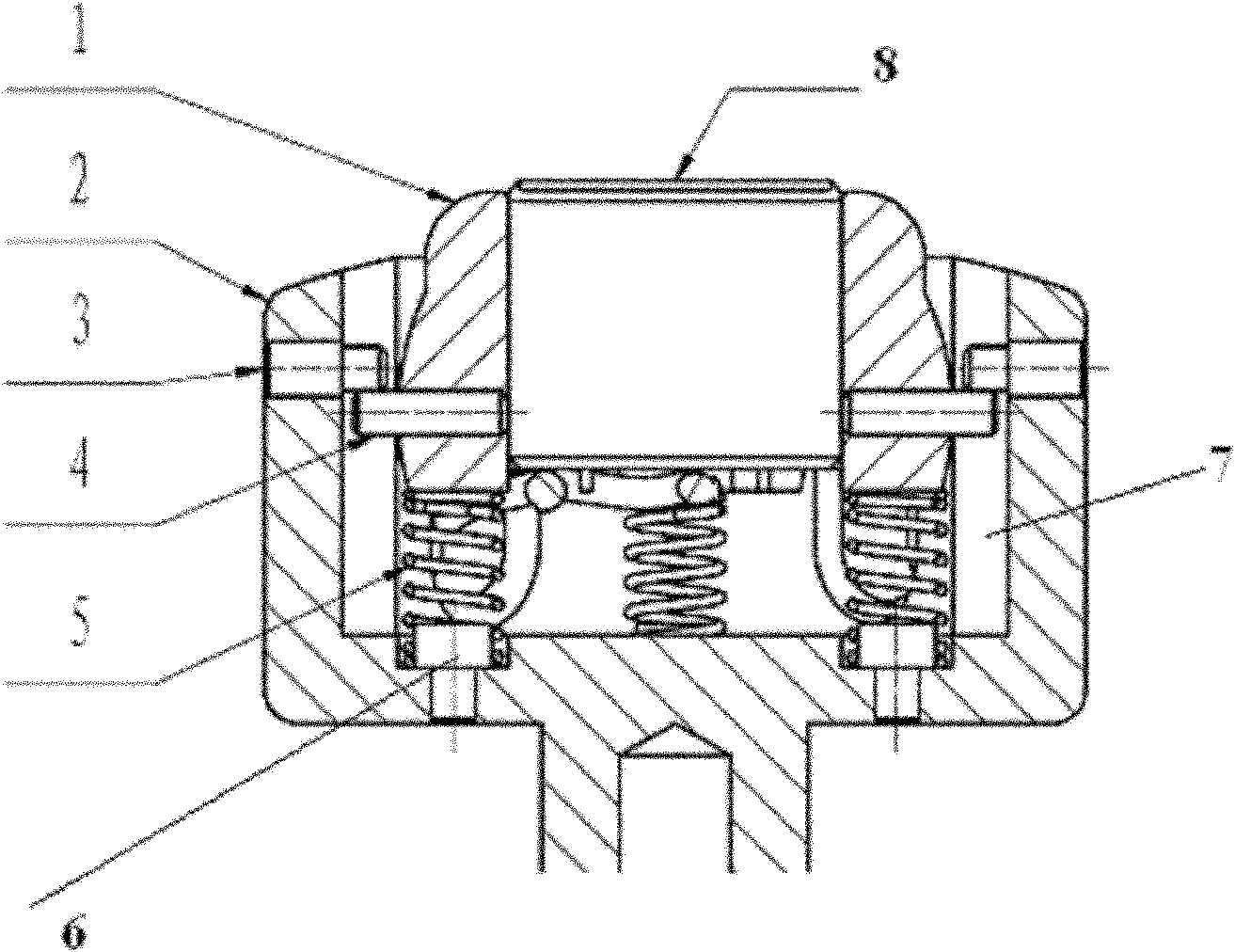

[0017] like figure 1 , figure 2 As shown: the non-destructive testing ultrasonic probe universal joint tray is composed of probe carrier 1 and probe tray 2. The main body of probe carrier 1 is a sphere with a square hole in the middle for installing probe 8. The square hole is in the same shape as probe 8 Matching, the probe 8 is fixed to the probe carrier 1 through two rotating set screws 4 symmetrically arranged on the probe carrier 1. There is a probe tray 2 outside the probe carrier 1, and the probe tray 2 is a semi-closed structure composed of a cylinder. The probe carrier 1 is installed at the opening of its upper end, and the lower end of the probe carrier 1 has a certain distance from the bottom surface of the probe tray 2. The probe carrier 1 cooperates with the cylindrical side of the probe tray 2 to form a universal structure, so that the probe 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com