Induction cooking appliance

一种感应加热、烹调器的技术,应用在感应加热烹调器领域,能够解决内部空间温度上升、感应加热烹调器吸气温度上升、无法加热线圈和电子部件冷却等问题,达到抑制温度上升的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

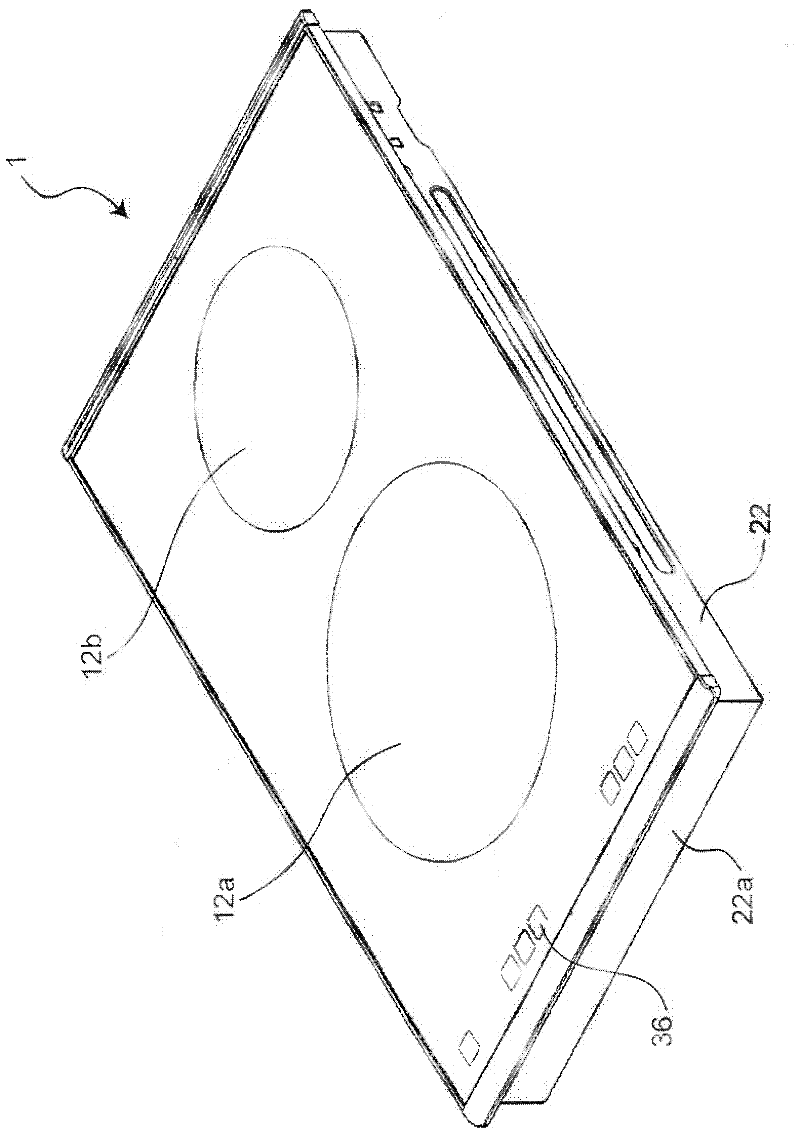

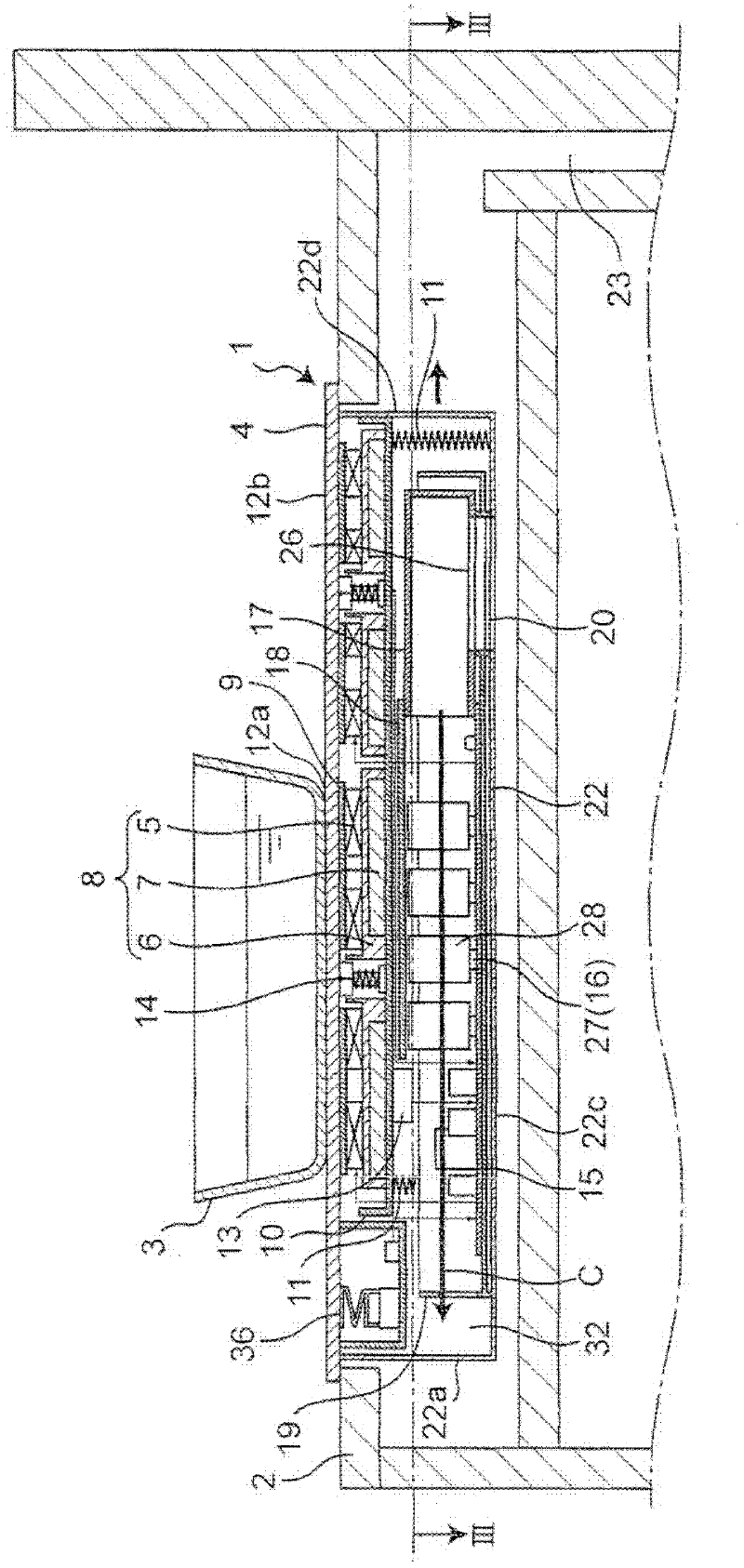

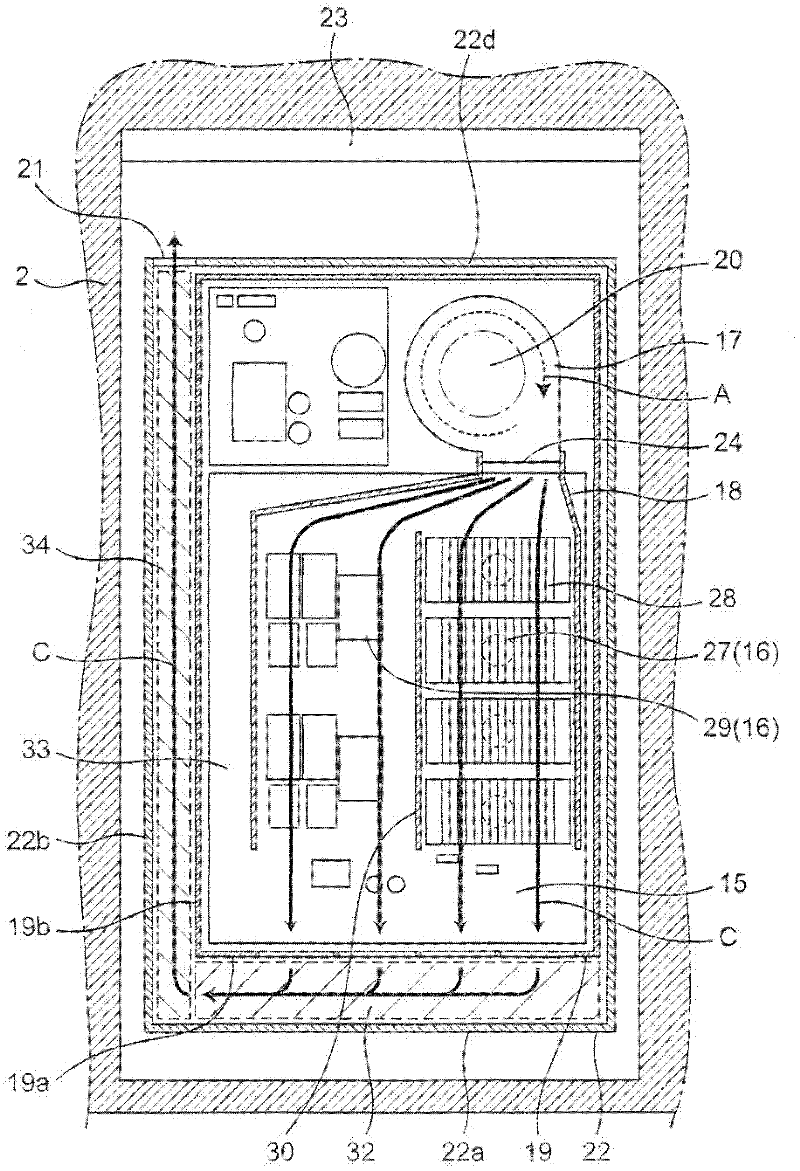

[0072] figure 1 It is a perspective view which shows the whole induction heating cooker which concerns on Embodiment 1 of this invention. figure 2 It is a cross-sectional view showing the installation state where the induction heating cooker according to Embodiment 1 of the present invention is assembled in a cabinet. image 3 It is a horizontal sectional view of the induction heating cooker according to Embodiment 1 of the present invention, and is figure 2 Sectional view of line III-III.

[0073] exist figure 1Among them, on the upper surface of the induction heating cooker 1, a top plate 4 on which a cooking container 3 or the like is placed as an object to be heated is provided. Two heating regions 12a, 12b are formed on the top plate 4 in the first embodiment. In the induction heating cooker 1, heating coils 5 for inductively heating the cooking vessel 3 etc. figure 2 ).

[0074] A heat-resistant resin coil holder 6 is provided below the heating coil 5 . A plu...

Embodiment approach 2

[0154] Hereinafter, an induction heating cooker according to Embodiment 2 of the present invention will be described with reference to the drawings. Figure 4 It is a horizontal sectional view showing the internal structure of the induction heating cooker according to Embodiment 2 of the present invention. In addition, in the induction heating cooker of Embodiment 2, since the basic structure is the same as the induction heating cooker 1 of Embodiment 1 mentioned above, it demonstrates centering on a difference. In the following description of Embodiment 2, constituent elements having the same functions and structures as those of the induction heating cooker 1 of Embodiment 1 are given the same reference numerals, and detailed description thereof is omitted, and the description of Embodiment 1 is followed.

[0155] like Figure 4 As shown, the induction heating cooker according to Embodiment 2 is configured such that the cooling air C from the blower 17 is guided by the duct ...

Embodiment approach 3

[0167] Hereinafter, an induction heating cooker according to Embodiment 3 of the present invention will be described with reference to the drawings. Figure 5 It is a horizontal sectional view showing the internal structure of the induction heating cooker according to Embodiment 3 of the present invention. In addition, in the induction heating cooker of Embodiment 3, since the basic structure is the same as the induction heating cooker 1 of Embodiment 1 mentioned above, it demonstrates centering on a difference. In the following description of Embodiment 3, constituent elements having the same functions and structures as those of the induction heating cooker 1 of Embodiment 1 are given the same reference numerals, and detailed description thereof is omitted, and the description of Embodiment 1 is followed.

[0168] like Figure 5 As shown, in the induction heating cooker according to Embodiment 3, the exhaust port 21 is formed on the back side of the left side wall 22b of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com