Optical fibre sensor and methods of manufacture

A technology of optical fiber sensor and optical fiber, which is applied in the direction of converting sensor output, cladding optical fiber, grating fiber, etc., and can solve problems affecting measurement reliability and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

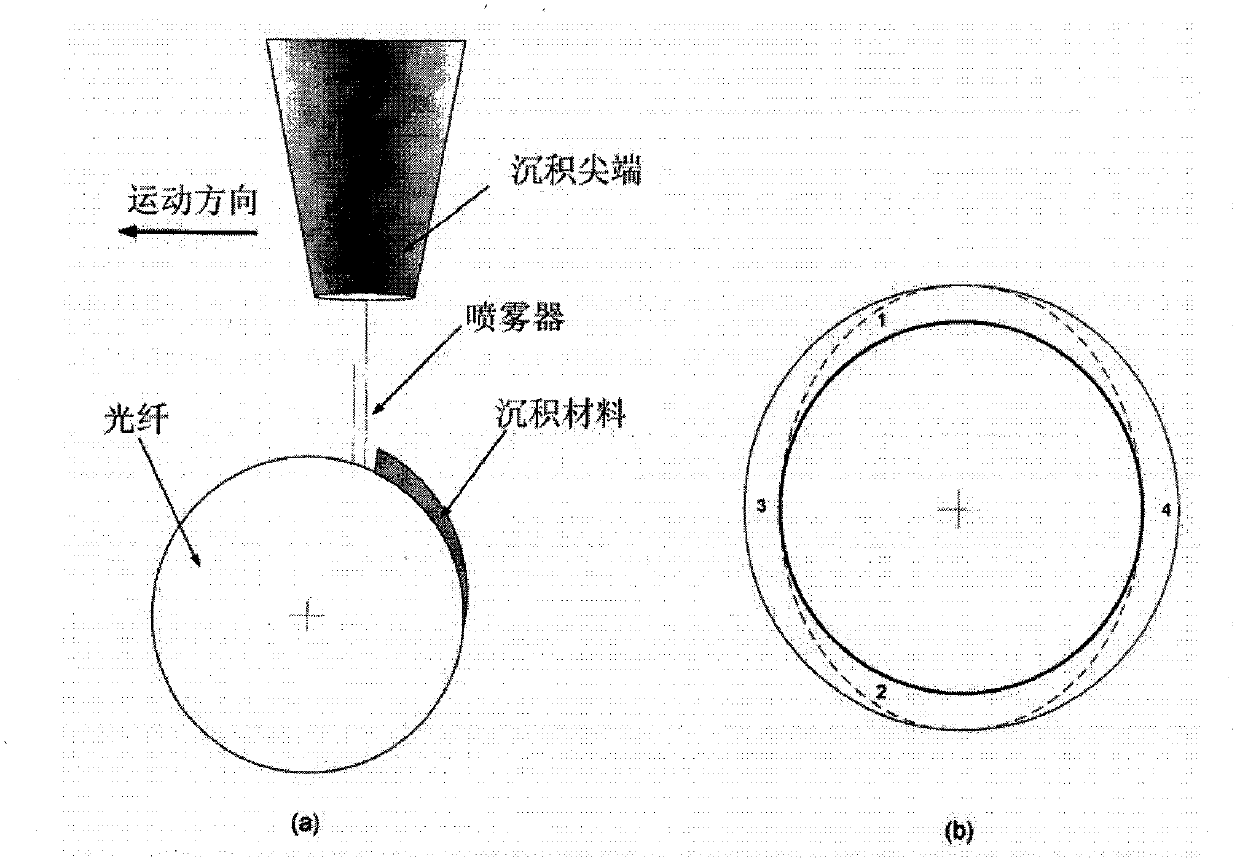

[0100] In summary, this description introduces a fiber optic sensor capable of simultaneously detecting and measuring multiple physical standards at one or more predetermined locations (also referred to as specific locations) on an optical fiber, and a fiber optic sensor made of such method.

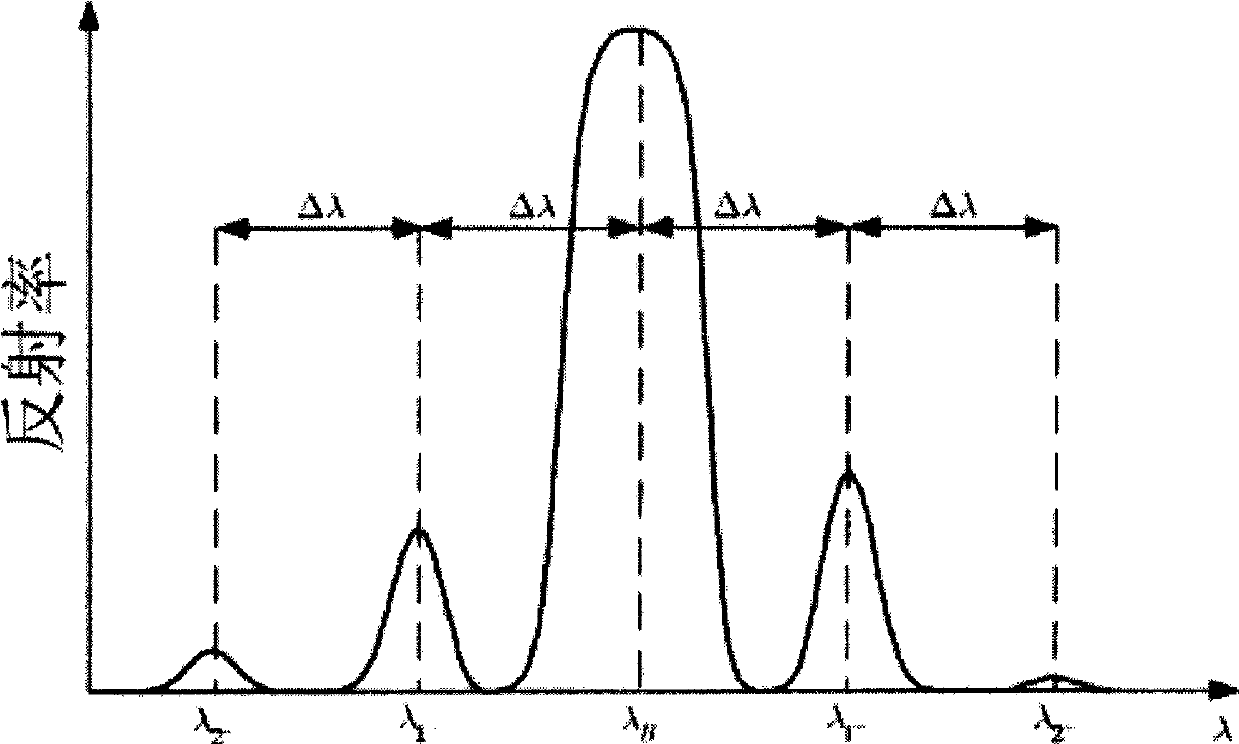

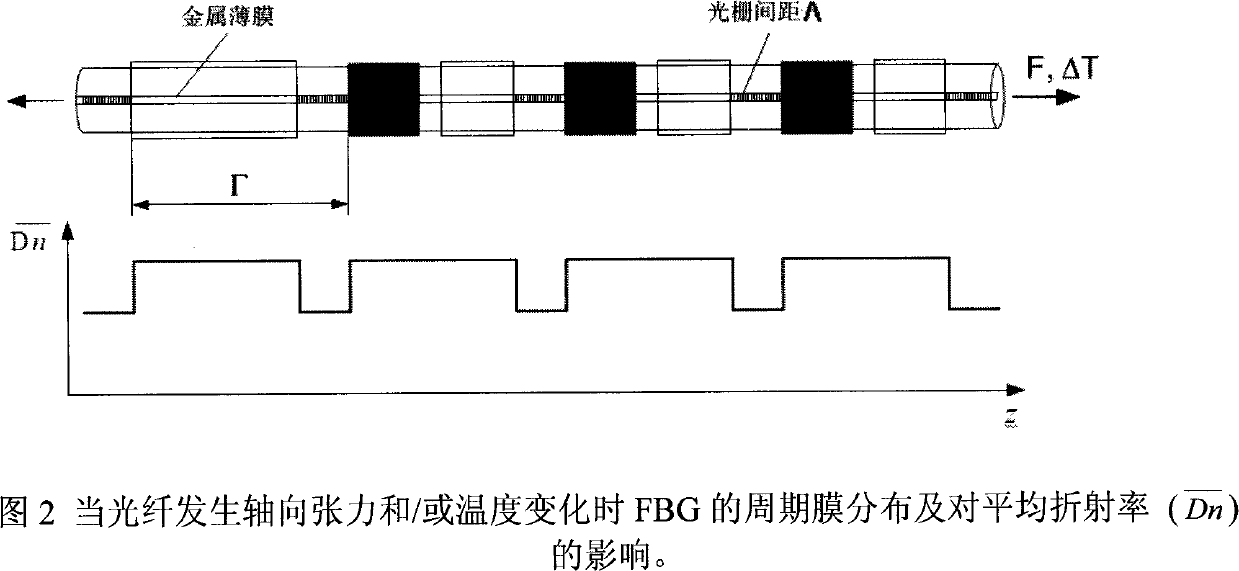

[0101] FBG has the function of adjusting the refractive index along the fiber core within the period L, which has been widely used in the detection of physical parameters and filtering. FBG sensors can be used to measure strength, stress, strain, pressure, and temperature. These functions are based on the optical sensitivity of FBG to strain and temperature. Compared with traditional electronic and electromagnetic devices, FBG has considerable advantages, mainly in light weight, small size, long service life, long-range linearity, and resistance to external electromagnetic corrosion.

[0102] SFBG is a kind of FBG whose refractive index is not adjusted uniformly but varies periodically ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com