Automatic measurement platform for river engineering model test

A river engineering model and automatic measurement technology, applied in measurement devices, fluid dynamics tests, and testing of machine/structural components, etc., can solve the problems of high labor intensity, complicated work, narrow and long area, etc. Efficiency and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

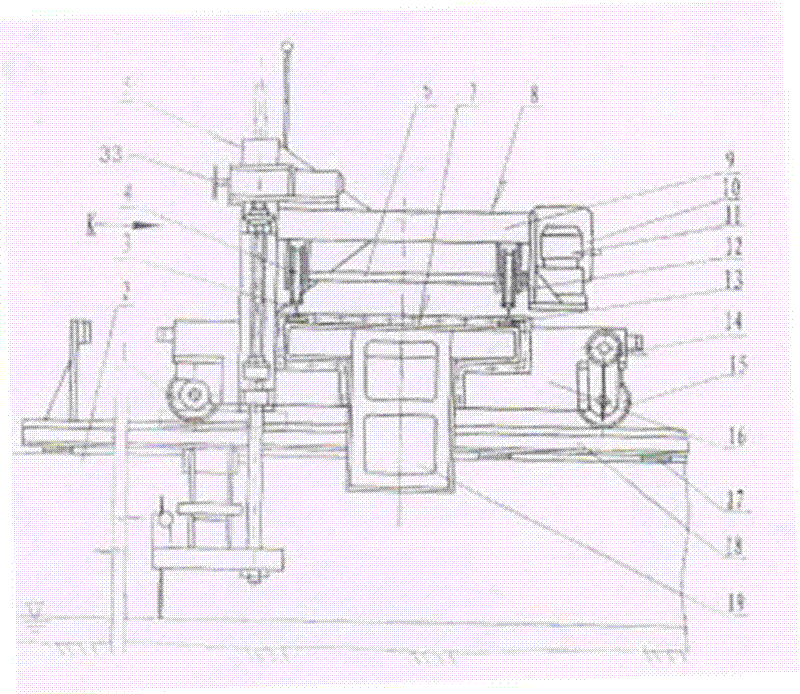

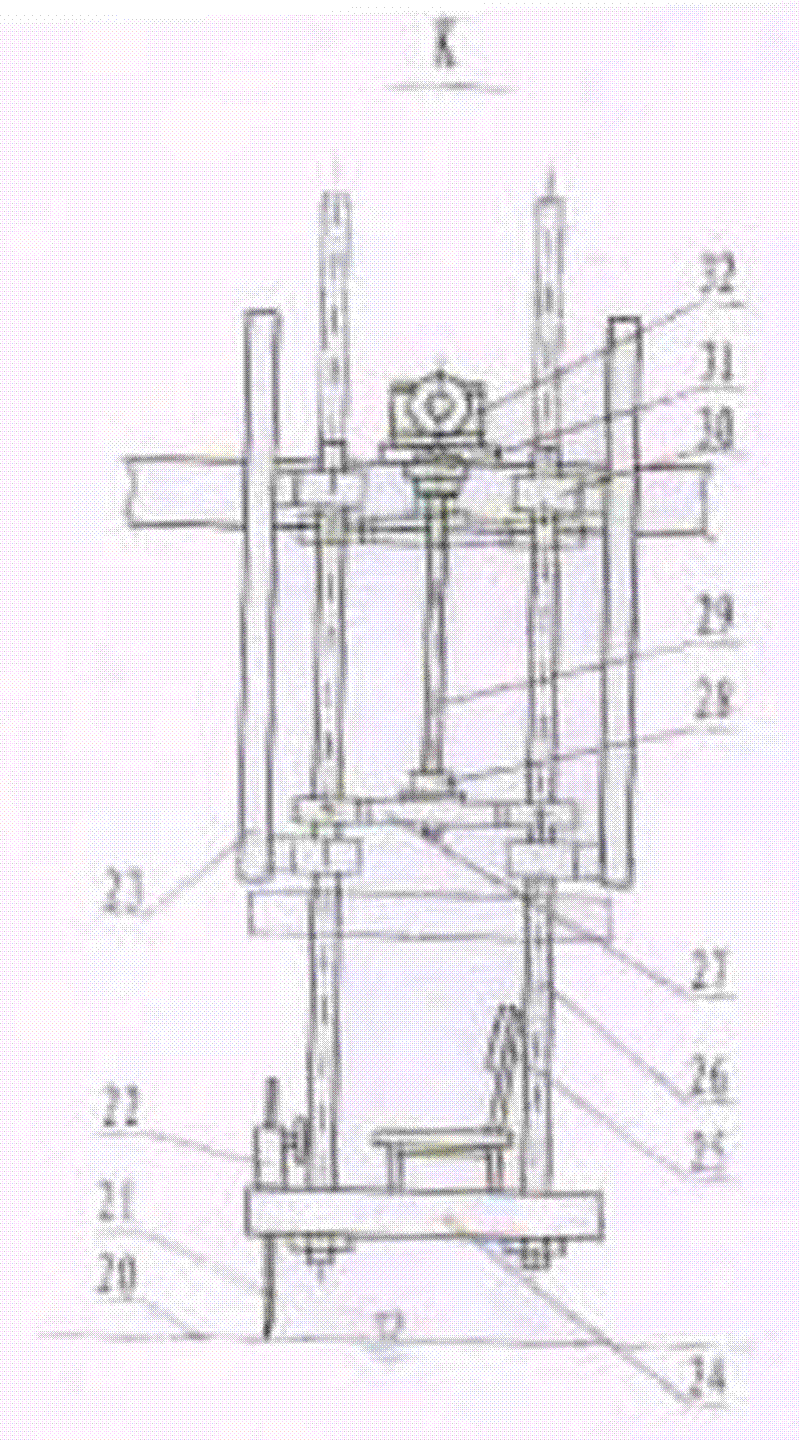

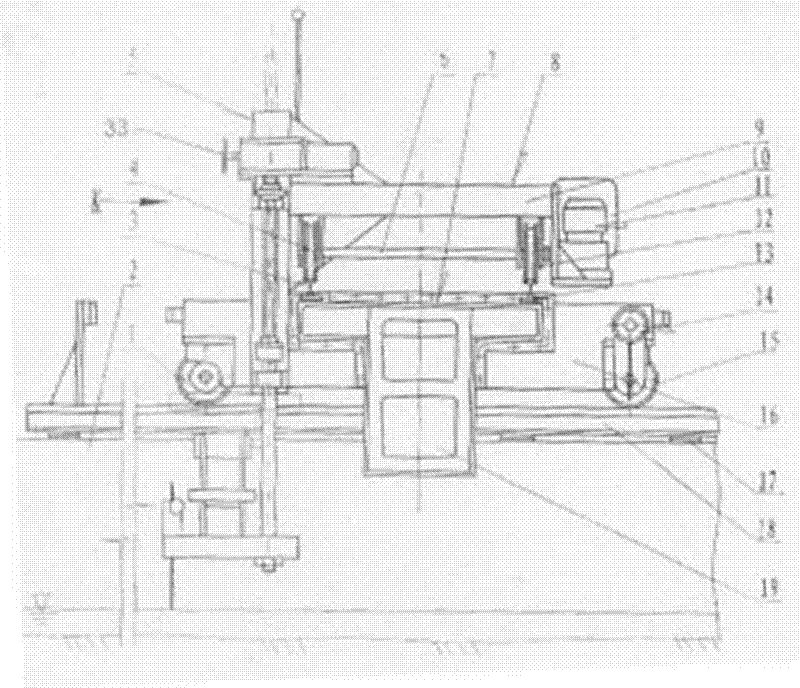

[0014] The automatic measurement platform for the river engineering model includes a cart 7 that straddles the river engineering model and walks along the X coordinate of the model, a trolley 8 that travels along the Y coordinate of the model on the main girder of the cart, and a vertical moving mechanism 5 fixed on the trolley along the Z coordinate of the model, connected to the vertical The measuring platform 24 on the mobile mechanism. Described cart 7 is made up of cart main beam 19, cart beam 16, cart active wheel assembly 14 and cart passive wheel 1. The cart main beam 19 is a box-type cart main beam welded by steel plate, and the cart main beam 19 two ends are all fixedly connected with a cart crossbeam 16, and one end of the cart crossbeam 16 at the two ends of the cart main beam is equipped with a cart active wheel assembly 14, The other end is equipped with cart passive wheel 1, and cart active wheel assembly comprises cart active wheel 15, electric motor, speed red...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com