Quasi-high speed gas burner for industrial stove

A gas burner and kiln technology, applied in the direction of burner, combustion method, combustion type, etc., can solve the problems of difficult use of high-speed burners, high price, complex structure, etc., and achieve long flame length, low cost and high rigidity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below through specific embodiments.

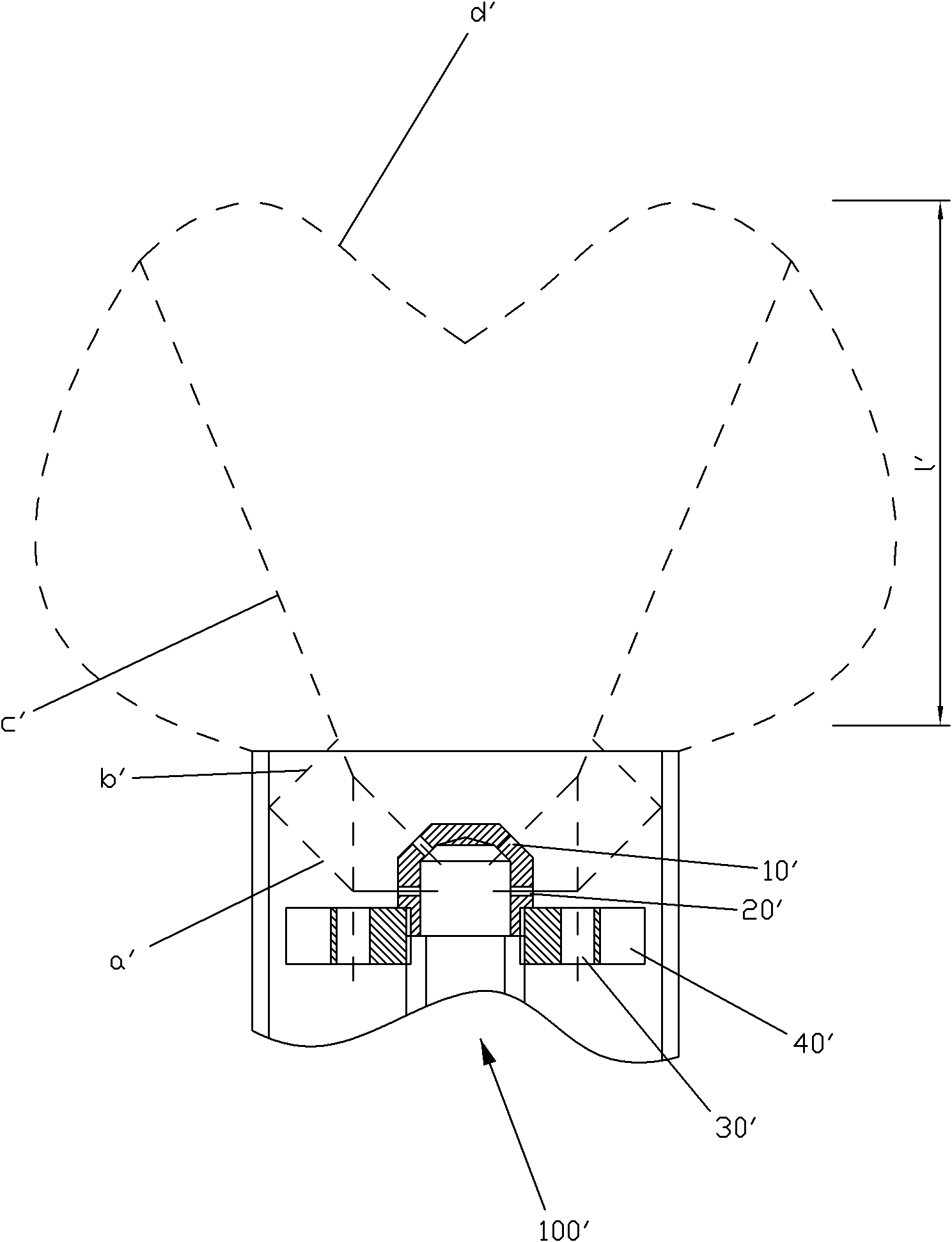

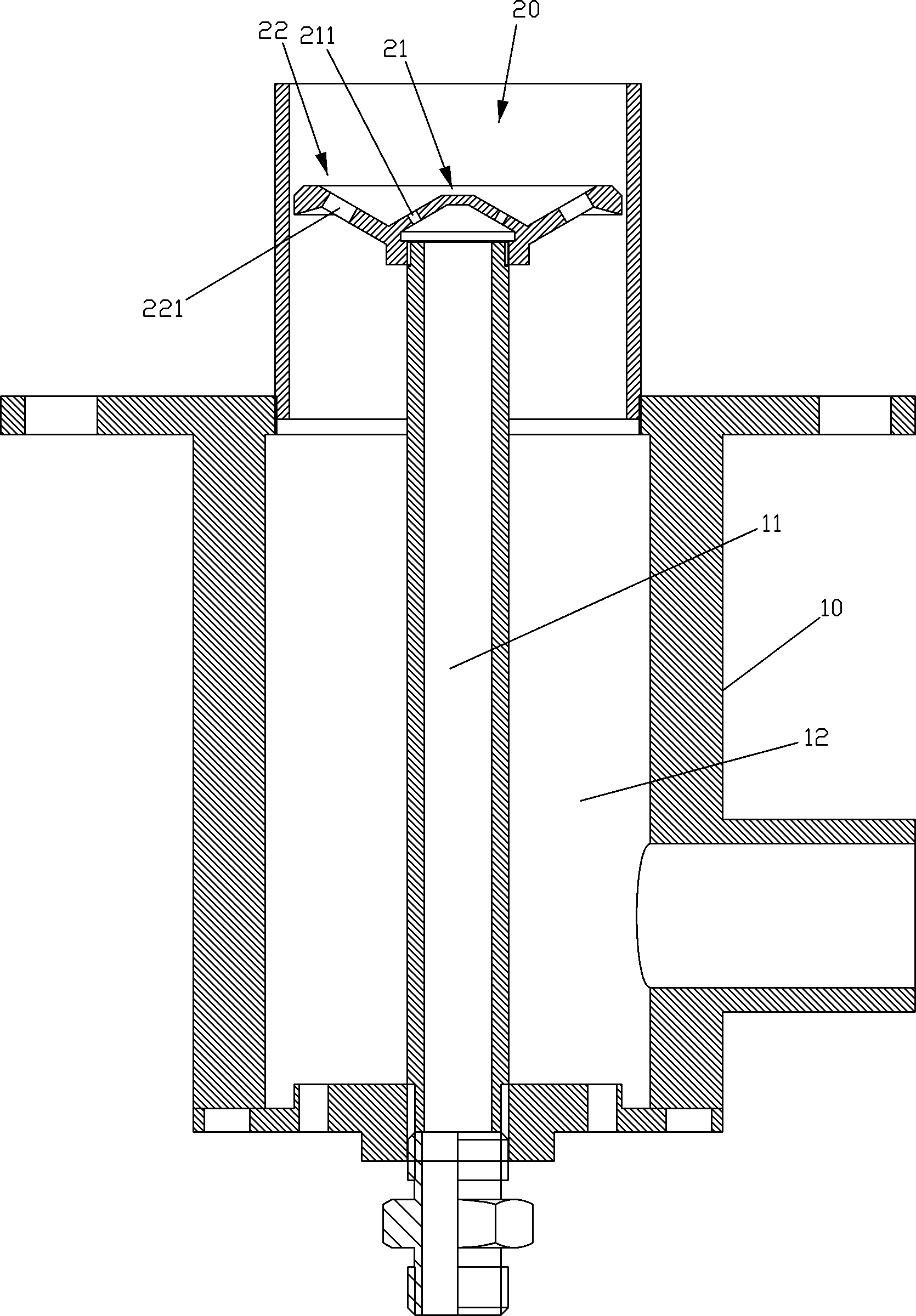

[0022] refer to figure 2 , a quasi-high-speed gas burner for an industrial kiln of the present invention, for example, can be a natural gas burner for a ceramic tunnel kiln, including a housing 10, which is provided with a gas passage 11 and a combustion air passage 12, and A mixer 20 is provided at the end of the gas passage 11 and the combustion air passage 12 .

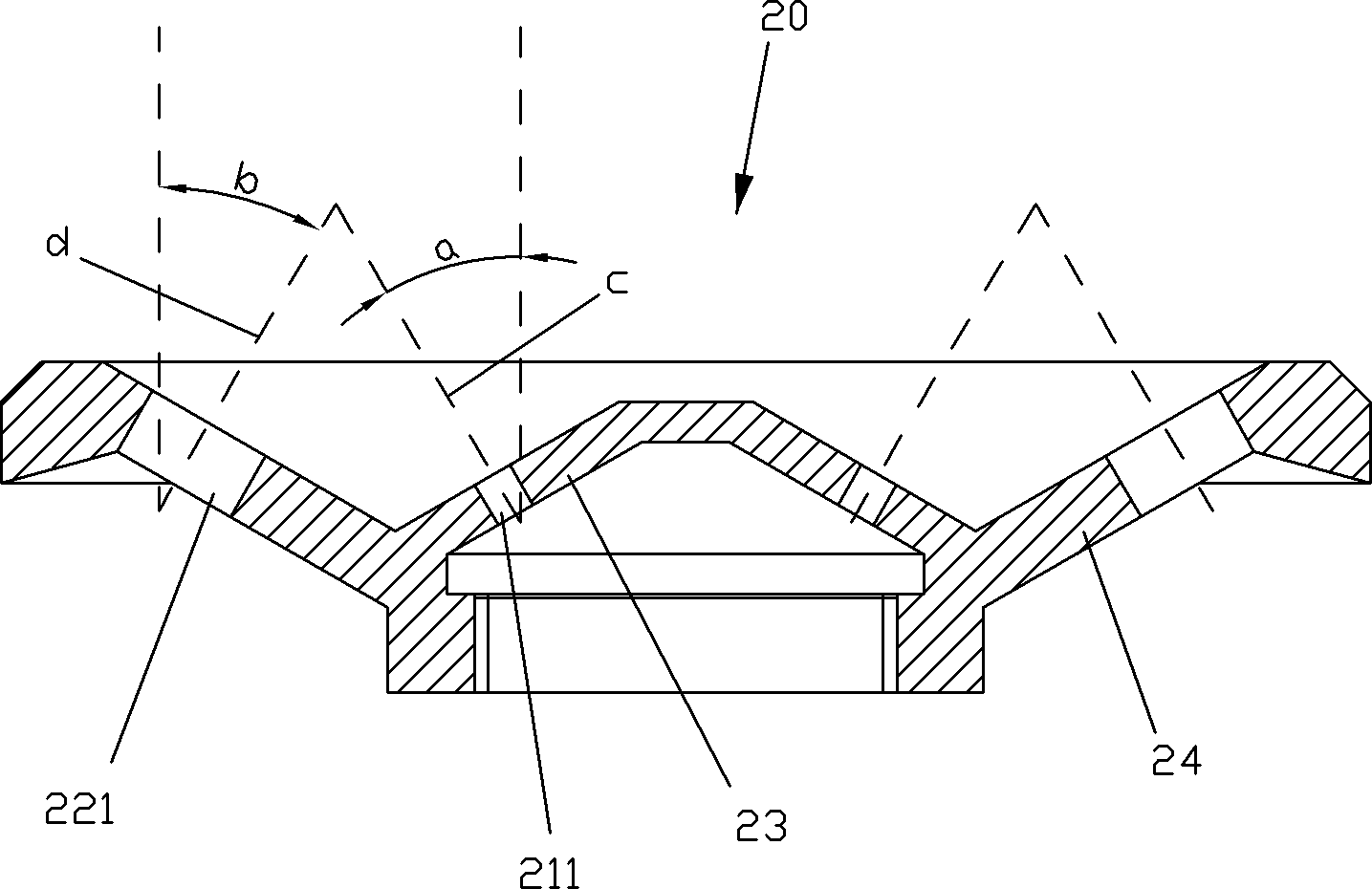

[0023] refer to figure 2 , image 3 and Figure 4 , The mixer 20 is an integral structure, and consists of a first mixing element 21 blocked at the end of the gas channel 11 and a second mixing element 22 blocked at the end of the combustion air channel 12 . The center of the first mixing element 21 protrudes upwards and slopes outward from the central protrusion to form a first inclined surface 23. The second mixing element 22 is arranged around the outside of the first mixing element 21 and slopes inward to form a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com