Novel double-row cylindrical roller bearing

A cylindrical roller bearing and cylindrical roller technology, applied in the directions of bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems that the size and coaxiality are difficult to ensure the same, and the clearance configuration is difficult to achieve the same two rows.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

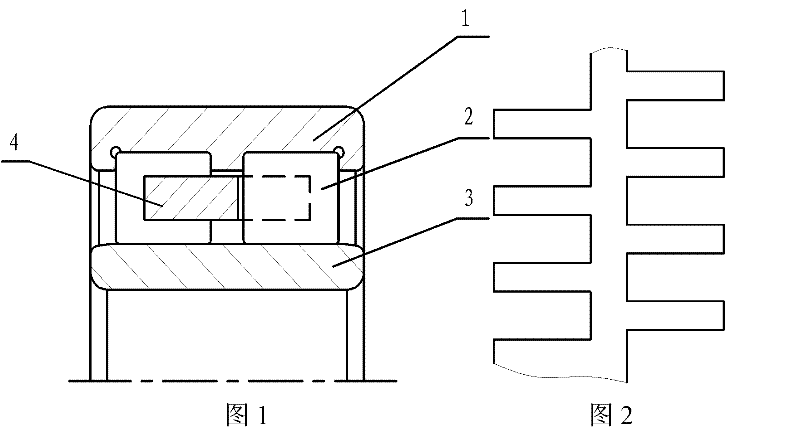

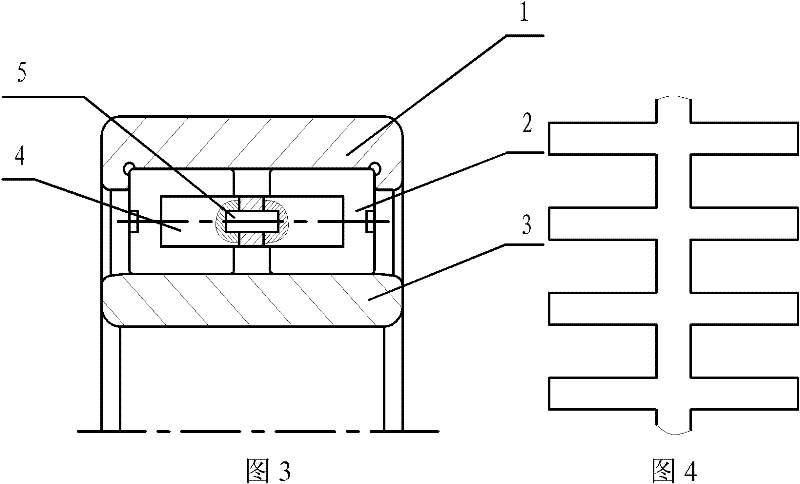

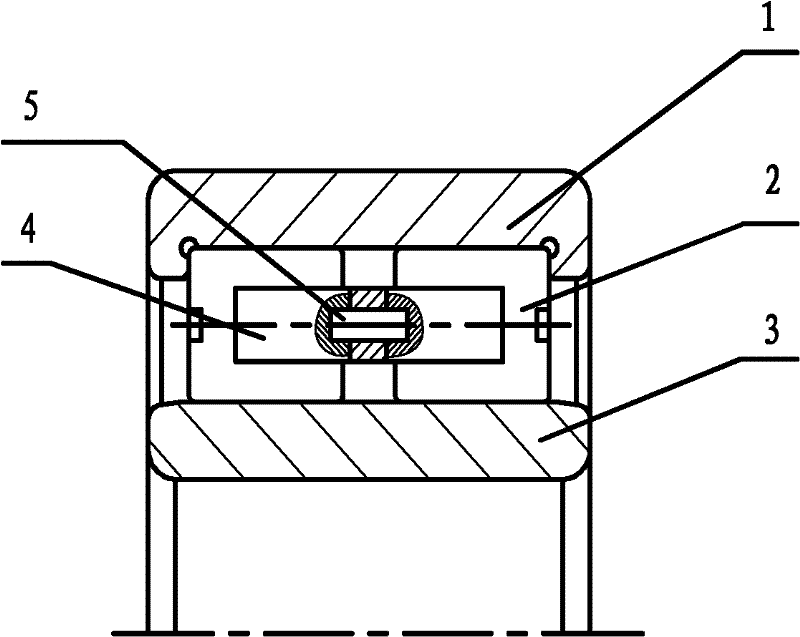

[0007] as attached image 3 , 4 The present invention represents a new type of double-row cylindrical roller bearing, which has an outer ring 1, an inner ring 3, a cage 4, and two rows of cylindrical rollers 2, and two rows of cylindrical rollers 2 and two rows of cylindrical rollers are arranged between the inner and outer rings. Cage for cylindrical rollers 4. The raceway of the outer ring matched with the two rows of cylindrical rollers is a single raceway containing the outer ends of the two rows of cylindrical rollers, that is, the raceway on which the two rows of cylindrical rollers roll is a straight-through raceway. Two parallel double-groove raceways form no ribs between the two rows of rollers, that is, the ribs in the existing outer ring are cancelled, so that the raceways of the two rows of cylindrical rollers can be ground at one time. The two raceway surfaces where the two rows of cylindrical rollers roll and the side surfaces of each side of the raceway can ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com