Integrally assembled steel-concrete superposed component and manufacturing method thereof

A technology of superimposed components and concrete, applied in the direction of building components, building structures, walls, etc., can solve the problems of poor structural integrity, weak function and force, large one-time investment, etc., to improve bearing capacity, small quality, reduce The effect of template engineering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

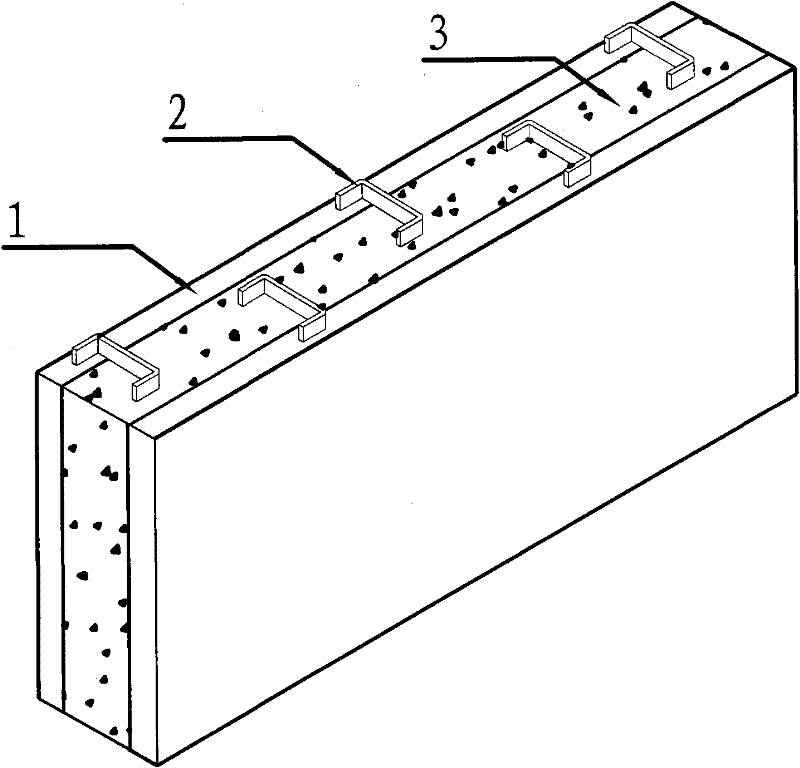

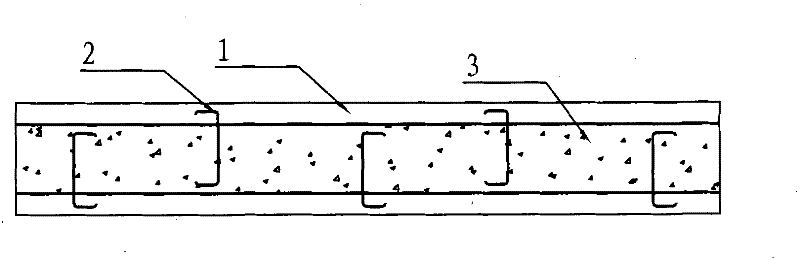

[0017] The assembled monolithic steel-concrete composite component is divided into two parts, one part is prefabricated and the other part is cast-in-place, and the walls and floors are integrally poured at the construction site.

[0018] When the prefabricated part is manufactured, steel mesh and steel frame are arranged inside the slab, part of the steel frame is buried in the prefabricated slab, and part of the steel frame is exposed outside and extends into the cast-in-place concrete. The steel skeleton increases the strength and rigidity of the prefabricated part. The inner surface of the prefabricated part is roughened to increase the bite with the cast-in-place concrete and improve the integrity of the laminated components.

[0019] Its specific production process is as follows:

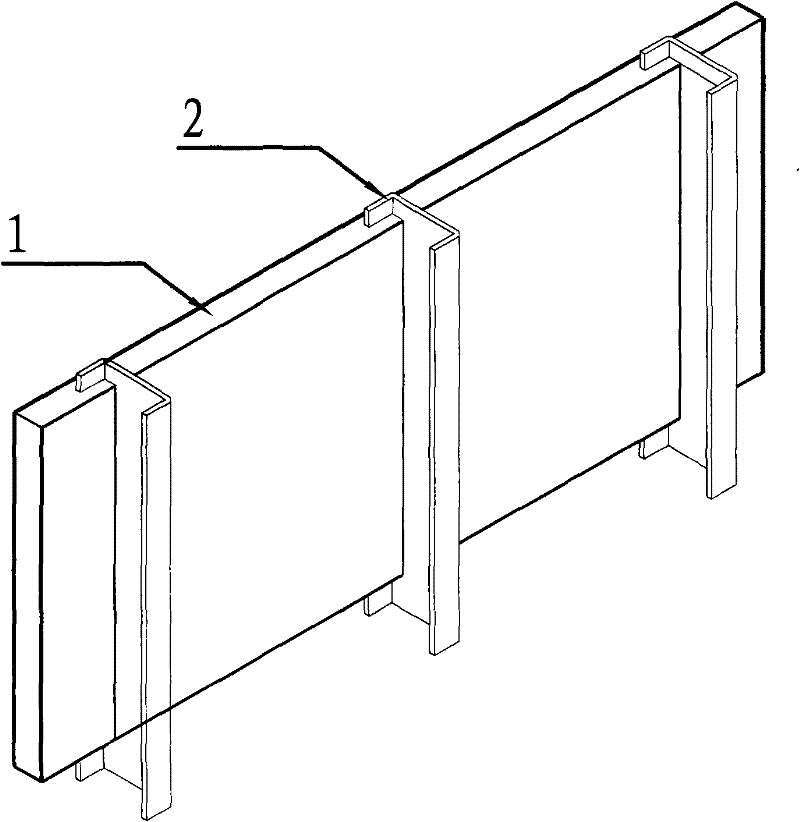

[0020] 1. If figure 1 Shown, the prefabricated part of the present invention comprises steel frame 2 and concrete 1; Arrange steel mesh and steel frame 2 on pedestal (or formwork), pour conc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com