Lubricant composition for internal combustion engines

A lubricating oil composition and the technology of the composition are applied in the field of lubricating oil compositions of gasoline and diesel engines, which can solve the problems of limited antioxidant properties, turbid additives, and high product cost, and achieve improved anti-friction and anti-wear performance, good High temperature cleaning, good economical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1~3

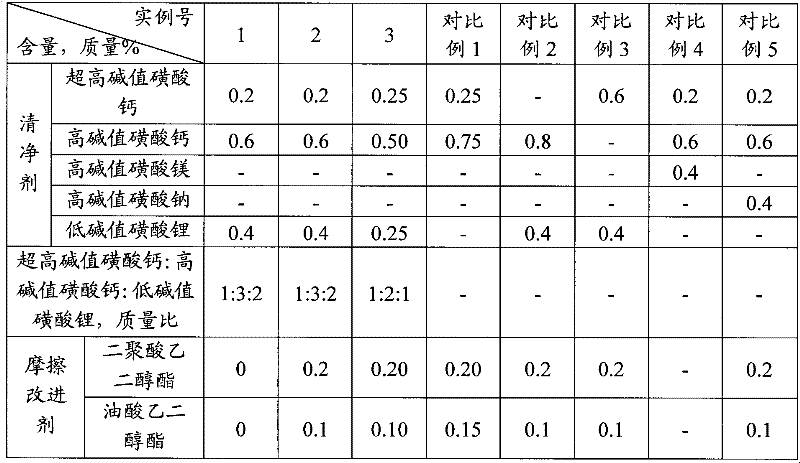

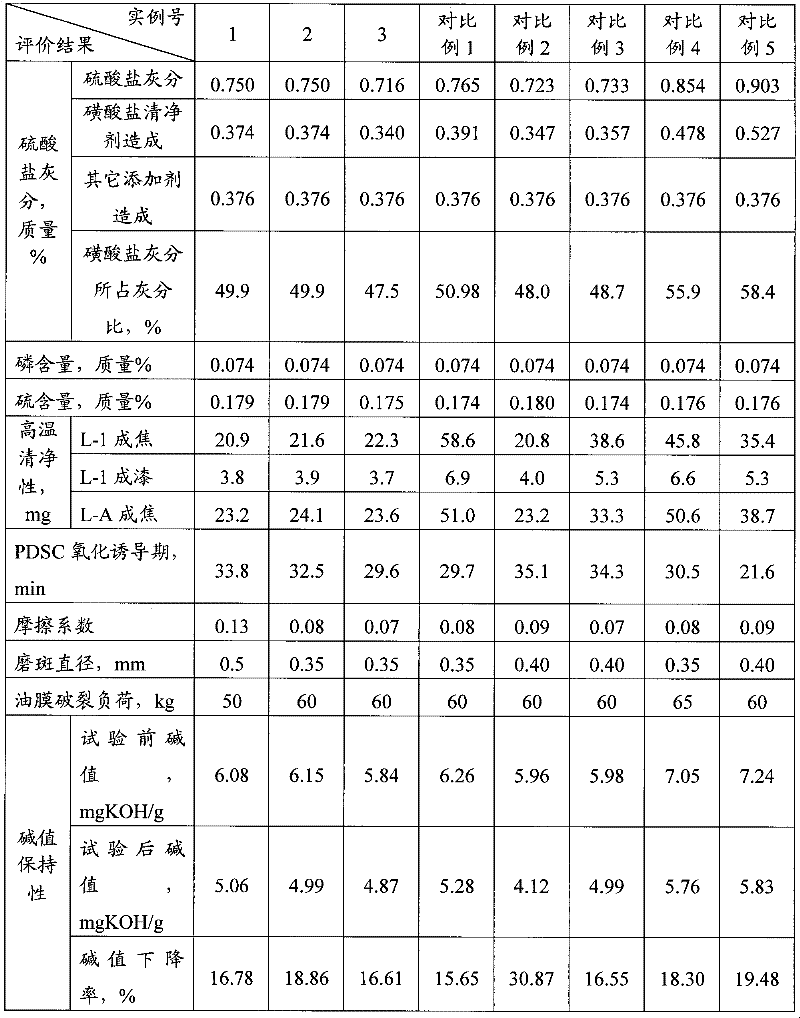

[0054] Compositions of the present invention are formulated.

[0055] 150SN, 500SN, and 150BS are prepared into base oil at a mass ratio of 14:5:1, and the viscosity at 100°C is 14.5mm 2 / s, its performance meets the requirements of 15W / 40 base oil.

[0056] Sulfonate detergents, friction modifiers, antioxidants, ashless dispersants, viscosity index improvers and pour point depressants are added to the prepared base oil to prepare lubricating oil compositions. The names and indicators of the additives used are as follows:

[0057] Sulfonate detergents:

[0058] Ultra-high base value calcium sulfonate: a base value of 405 mgKOH / g, a calcium content of 14.5% by mass, and a sulfur content of 1.43% by mass.

[0059] High base value calcium sulfonate: a base value of 311 mgKOH / g, a calcium content of 10.2% by mass, and a sulfur content of 1.8% by mass.

[0060] Low base value lithium sulfonate: a base value of 135 mgKOH / g, a lithium content of 1.91% by mass, and a sulfur content...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com