Novel sewage treatment technology

A sewage treatment and sewage technology, which is applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, etc. problems such as large energy consumption, to achieve the effect of saving workload, saving energy, and reducing infrastructure costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

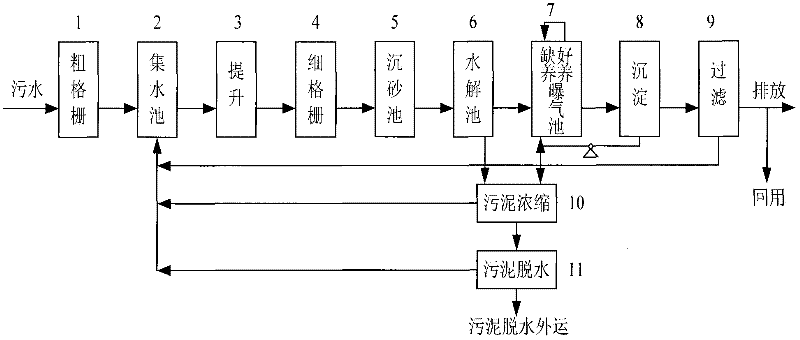

[0023] Sewage (COD400mg / L, BOD200mg / L, SS250mg / L) passes through the coarse grille 1, the gap of the coarse grille is about 20 mm, and removes large debris to protect the normal operation of the lift pump, and the sewage enters the sump 2 , use a submersible pump to lift the sewage 3, the sewage enters the fine grid 4, the gap of the fine grid is about 1 mm, and removes small sundries (removal of COD15-20%); it can basically replace the bulky primary sedimentation. Sewage enters grit chamber 5, COD350 mg / L, BOD185 mg / L, SS150 mg / L. The sewage after grit settling enters the hydrolysis tank 6. The hydrolysis tank is an empty structure without filler, agitator and phase separator. There are only pipelines for sending sewage. Sludge bed, the sewage (contained in the hydrolyzed bacteria sludge itself) is controlled at a speed of 1-2 m / m in the hydrolysis tank, and the water stays in the hydrolysis tank for about 2-4 hours. The sewage can remove fine suspended matter through the hyd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com