Fastening plate

A fastening plate and fastening technology, applied in the direction of locking fasteners, threaded fasteners, screws, etc., can solve the problem that the anchoring part endangers the fastening of the fastening plate and the concrete, and it is difficult to ensure the proper operation of the thread of the threaded connection, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

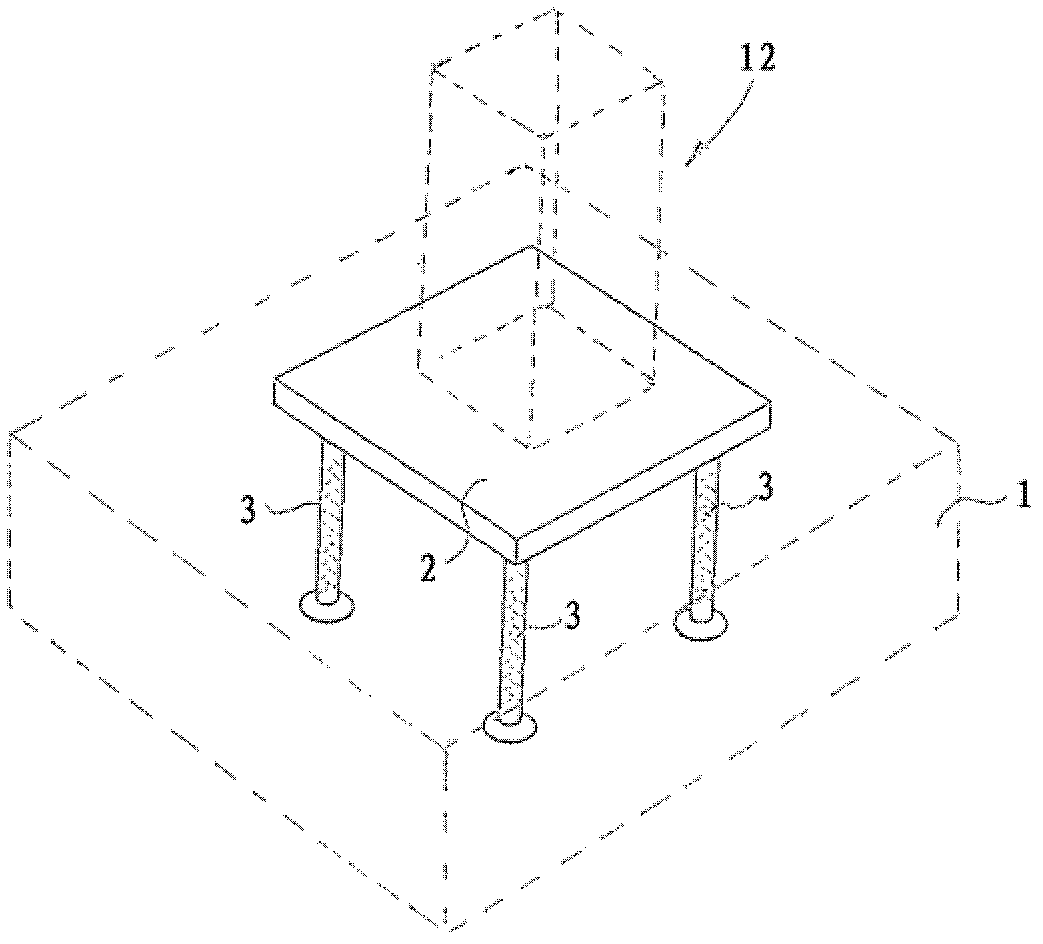

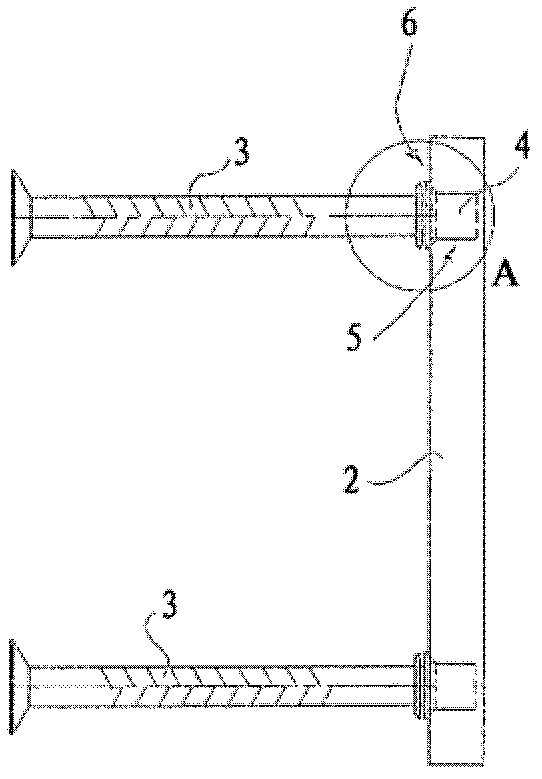

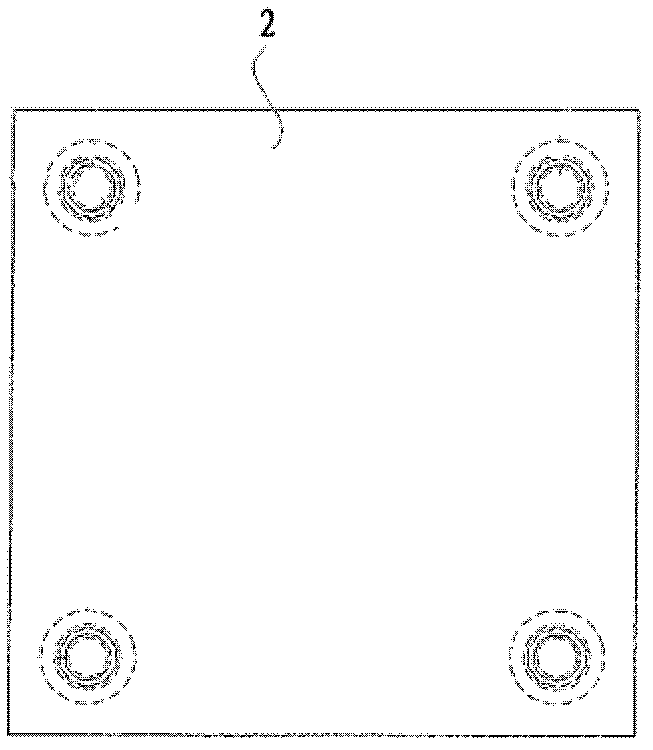

[0013] figure 1 The principle of a fastening plate engaged with a concrete structure 1 is shown. The fastening plate comprises a plate part 2 and an anchor part 3 . Structural fasteners 12 are fastened to the plate portion 2 . The anchoring part 3 can be fastened to the plate part 2 by welding or screwing, for example. The fastening plate is placed in the concrete before the concrete dries, whereby the fastening plate is fastened in the concrete while the concrete is hardening.

[0014] exist figure 1 The concrete structure 1 and the structural fasteners 12 are shown in dotted lines. The concrete structure 1 may be any known structure. Thus, the structural fastener may be of any construction known per se. For example, different structural elements of a building can be fastened to the structural fasteners 12, thereby transferring the forces and loads caused by these structural elements to the concrete via the fastening plates. These facts are known to those skilled in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com