Bobbin holder

A bobbin rack and bobbin tube technology, applied in the field of bobbin racks, can solve the problems of fixed filament clamping force reduction, wire catching errors, aging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

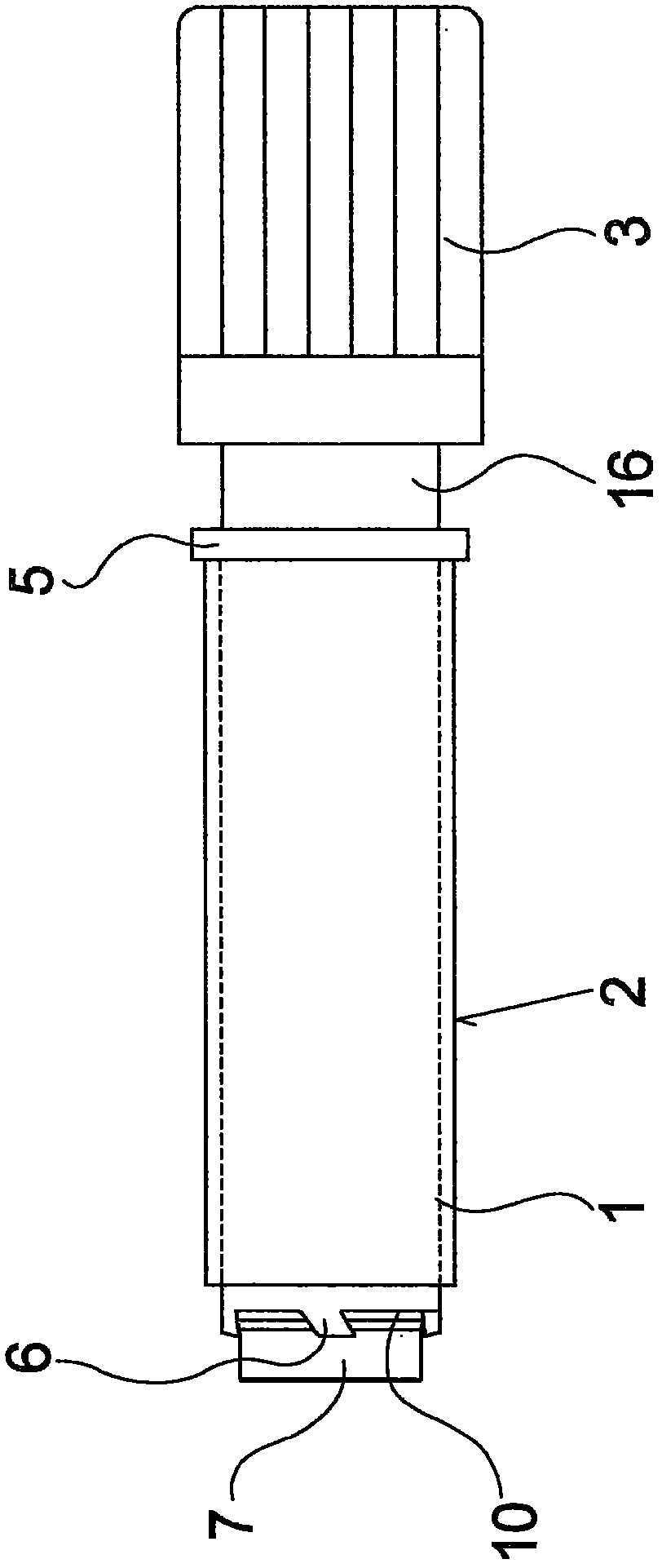

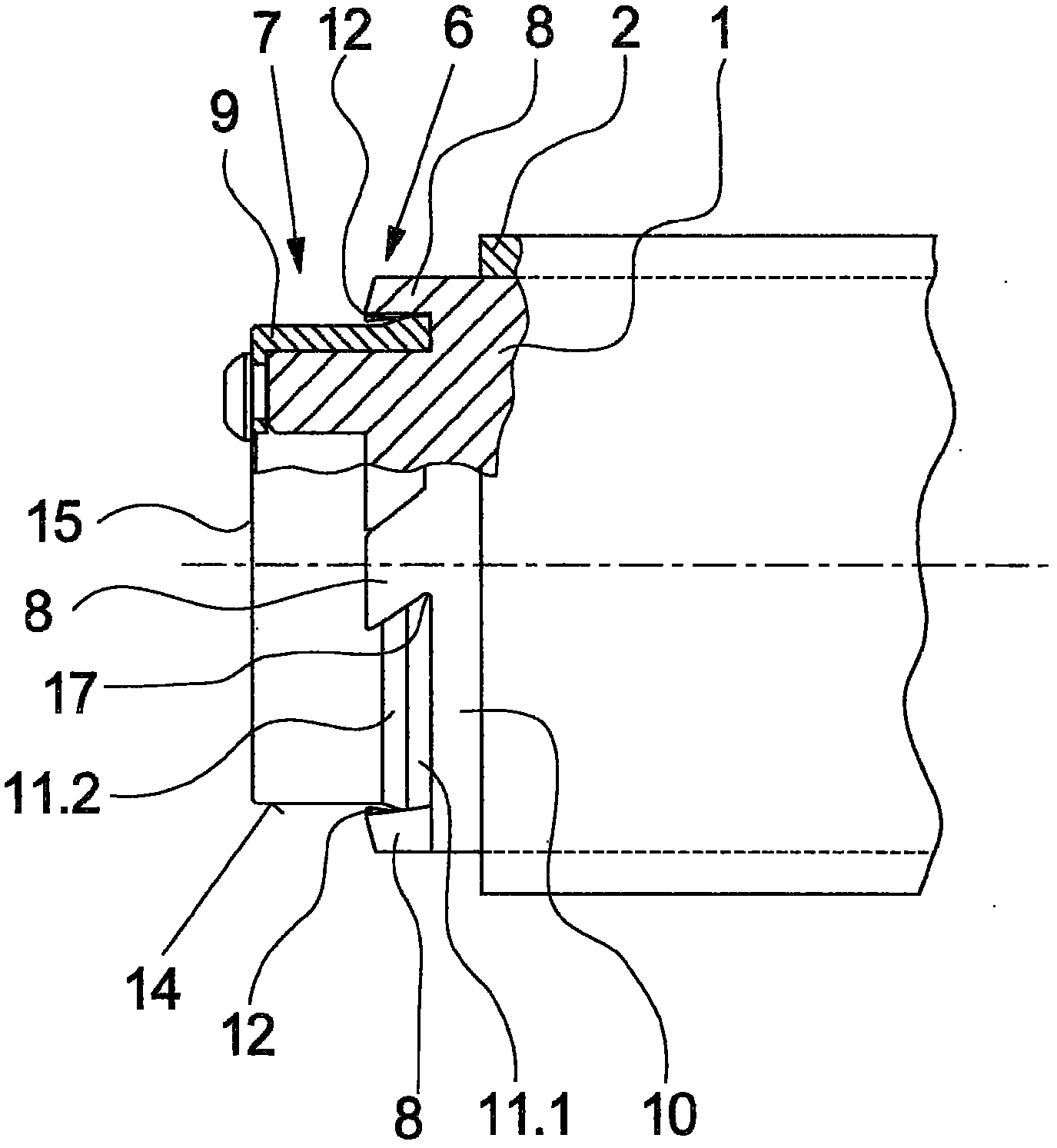

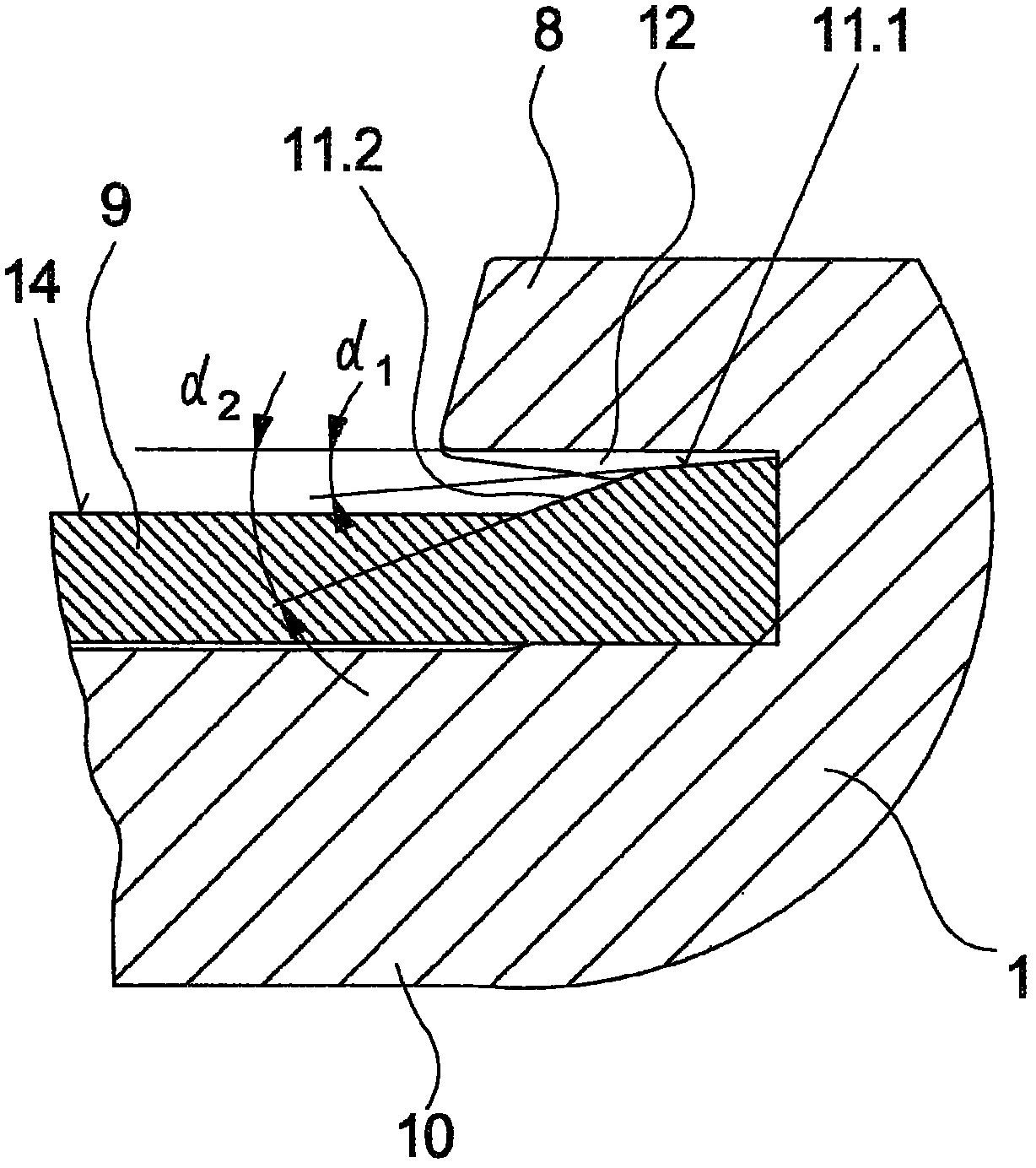

[0025] figure 1 A first embodiment of the bobbin holder of the present invention is schematically shown in FIG. The bobbin holder has an overhanging bobbin spindle 1 which supports a bobbin 2 on its circumference. The bobbin 2 is pushed up to a stop 5 on the bobbin spindle 1 and is clamped by a clamping mechanism on the casing of the bobbin spindle 1 (not shown here). The bobbin spindle 1 is coupled to a motor 3 at the drive end 16 . The bobbin spindle 1 has a thread catcher 6 and a thread clamping element 7 on the opposite push-in end 10 .

[0026] Such bobbin holders are commonly used in winders to wind continuously fed filaments into spools on the circumference of a bobbin. One such winder is known from WO 2007 / 073860 A1. Here, reference is made to said literature in this regard. In such a winder, two bobbin holders arranged at a distance from each other are fixed on a turntable, so that the bobbin holders can be moved alternately into a winding area for winding the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com