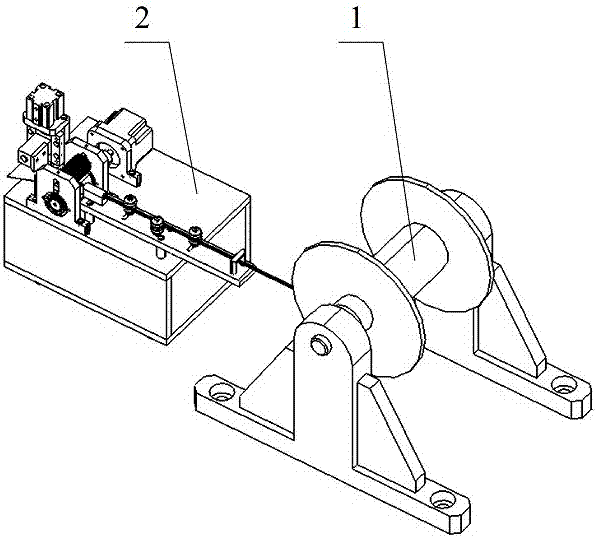

Automatic length measuring and cutting machine for ribbons

A cutting machine and cable tie technology, which is applied in metal processing and other directions, can solve the problems of low work efficiency and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

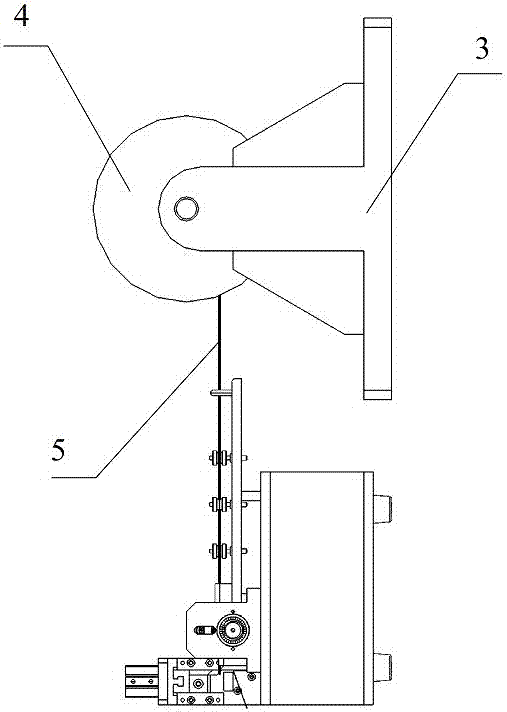

[0045] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

[0046] Manually pull out the 5, cable tie on the 4, cable tie reel.

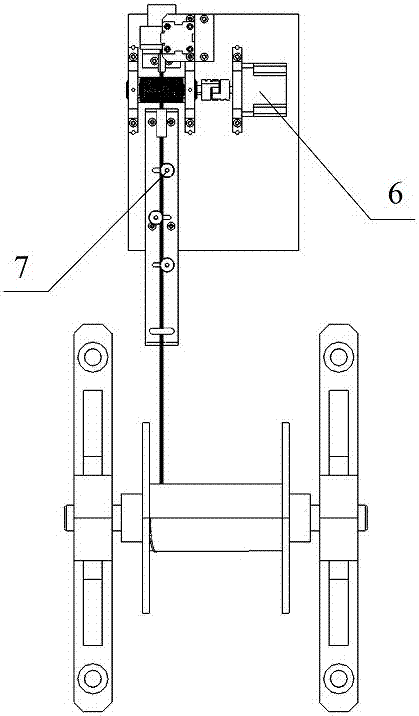

[0047] Further, pass the pulled out 5, cable tie through the gap between 7, 10, front straightening roller, 11, and rear straightening roller of the cable tie straightening assembly.

[0048] Further, 5, cable tie is passed through the gap between 9, 13, driving roller, 12, knurling driven roller of opposite roller drawstring assembly again.

[0049] Further, use 9, 12, knurled driven rollers to compress 5, cable ties to the roller drawstring assembly.

[0050] Further, 6, the servo motor of the electrical control system starts.

[0051] Further, compress the 9 of the cable tie, the 13, the driving roller, 12, and the knurled driven roller of the pull belt assembly against the roll, and continuously pull the 5, cable tie from 1, the cable tie reel part 4. Pull out the cable tie ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com