X-ray tube with bonded target and bearing sleeve

A technology of X-ray tube and bearing sleeve, which is applied in the direction of X-ray tube, X-ray tube electrode, X-ray tube cooling, etc., can solve inefficient heat transfer, improper X-ray tube temperature, and does not allow continuous X-ray tube Operation and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

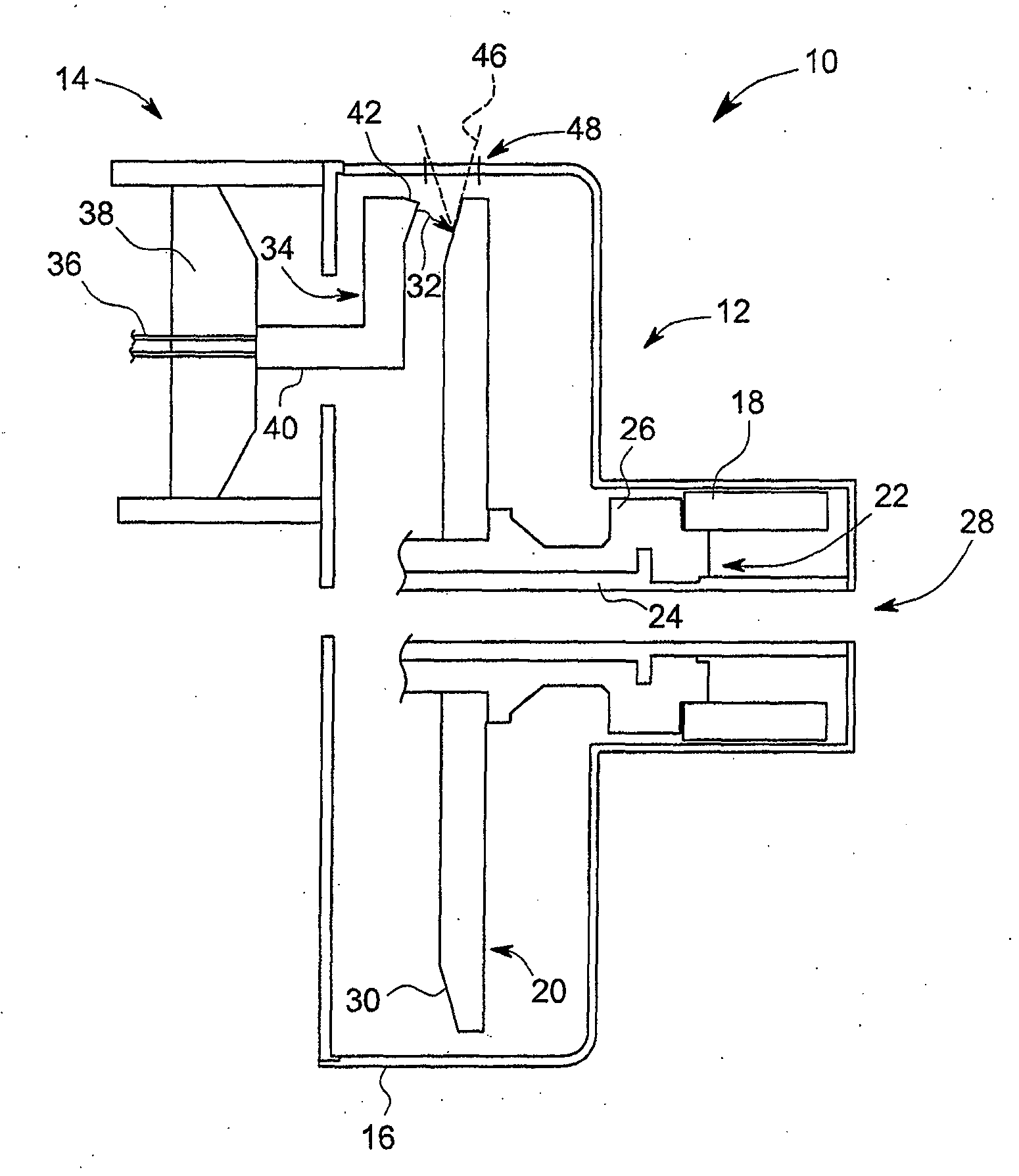

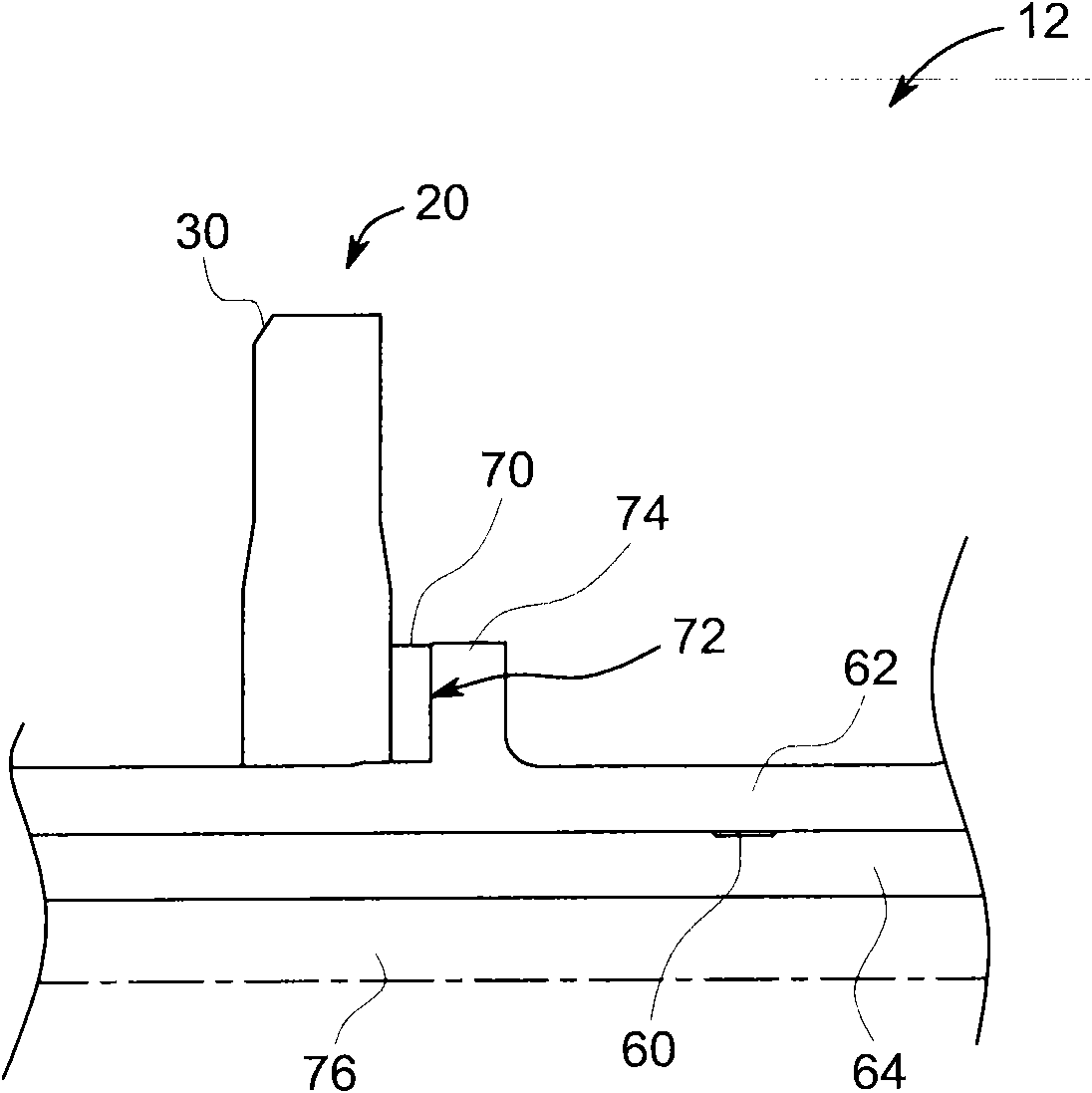

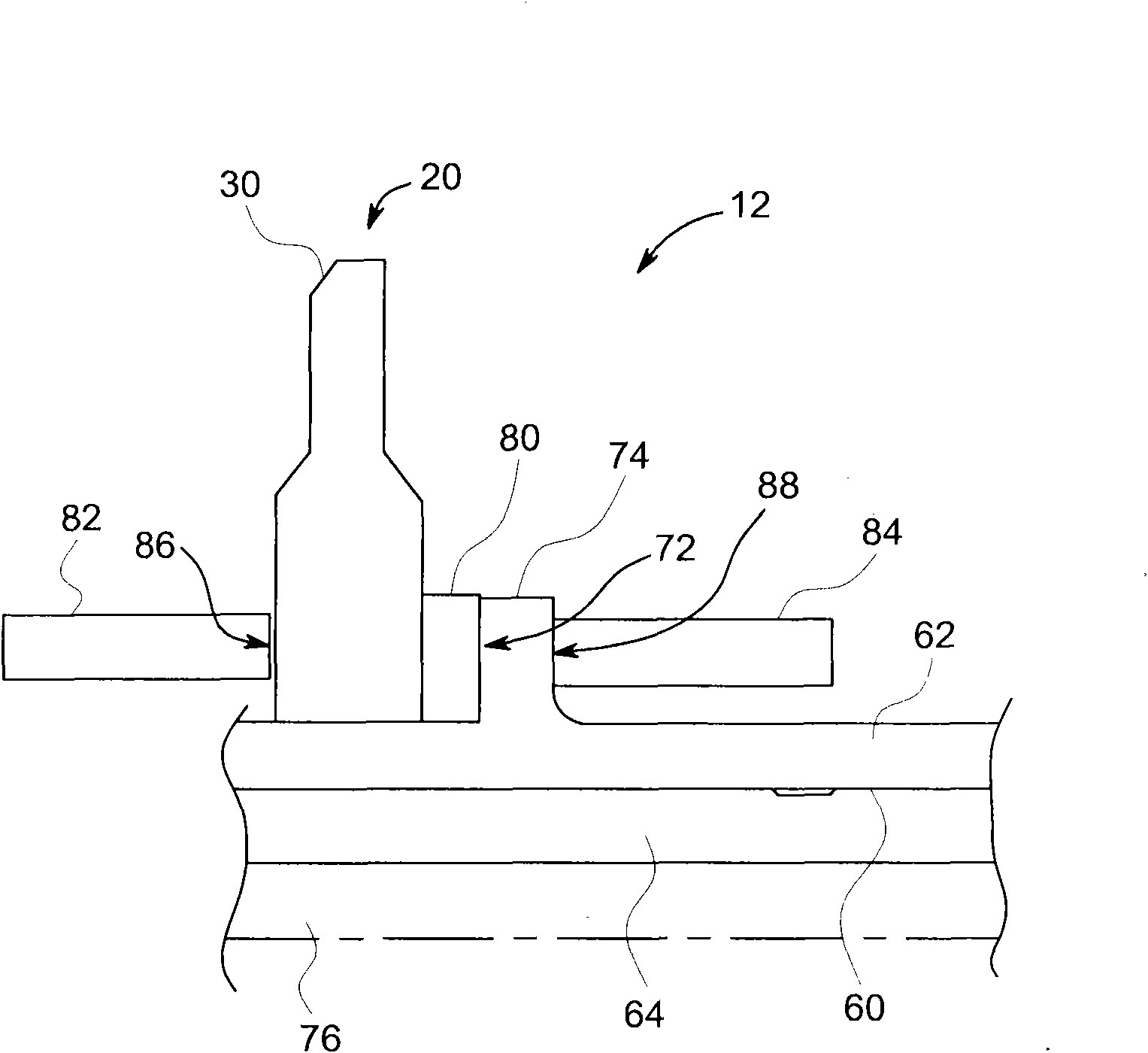

[0015] As noted above, heat conduction between the various components of the X-ray tube can be important to allow continued use of the X-ray tube and the utilization of high power (ie, high X-ray flux) imaging sequences. An example of an imaging sequence that would benefit from high X-ray flux is a computed tomography (CT) imaging sequence in which a source of X-ray radiation (i.e., a source including an X-ray tube) surrounds a patient or subject of interest on a gantry. The examiner moves. Due to the movement of the x-ray tube around the patient, it is desirable to provide a flux of x-rays sufficient to generate imaging through the subject of interest and at low noise levels. Accordingly, there is a continuing need for improved heat conduction away from an X-ray target in an X-ray tube.

[0016] For some x-ray targets, there may be several design considerations including heat conduction, retention of the target limiting target movement, and maintenance of bearing tolerances....

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com