Multipoint sensor FWD (Falling Weight Deflectometer)

A drop-weight deflectometer and sensor technology, used in instruments, scientific instruments, and the use of one-time impact force to test the strength of materials, etc., can solve the problems of difficult maintenance, complicated operation control, etc., to simplify the lifting structure and enhance the stability of the structure. , the effect of improving the measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the drawings.

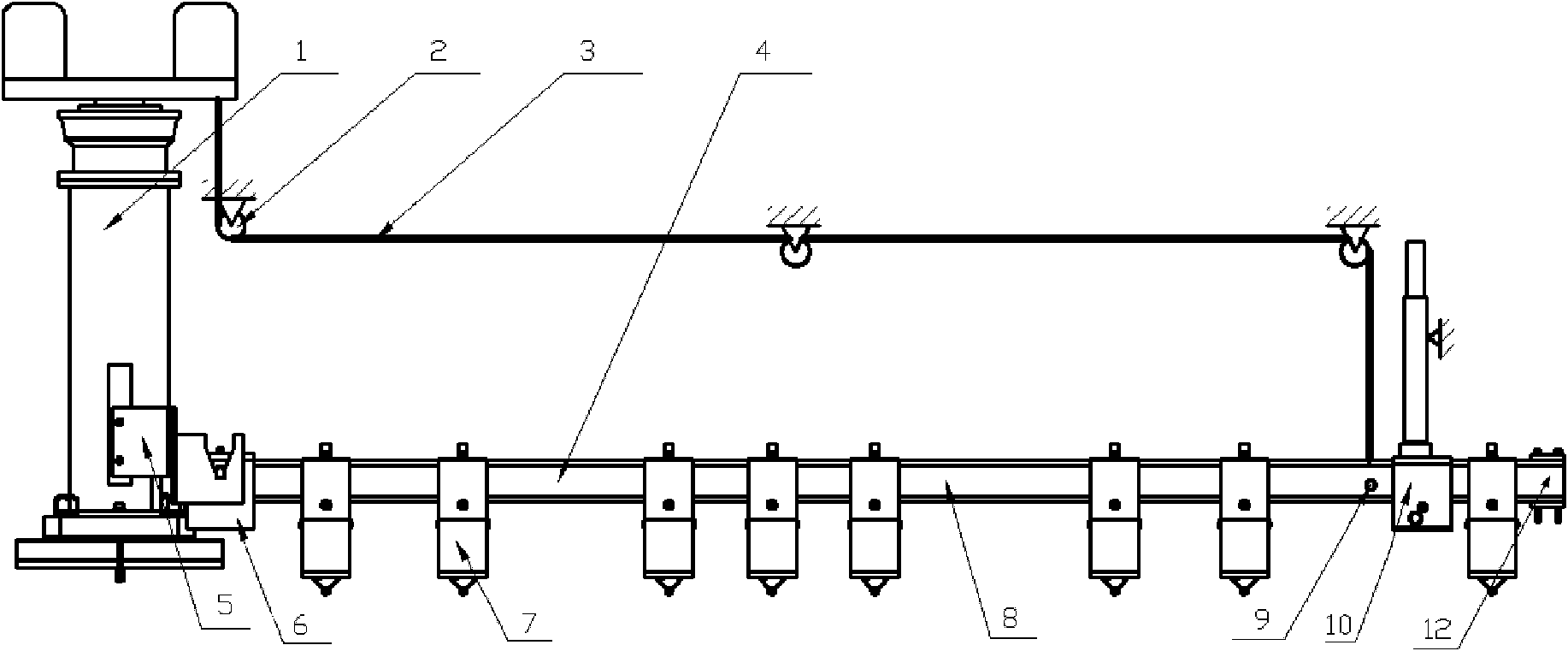

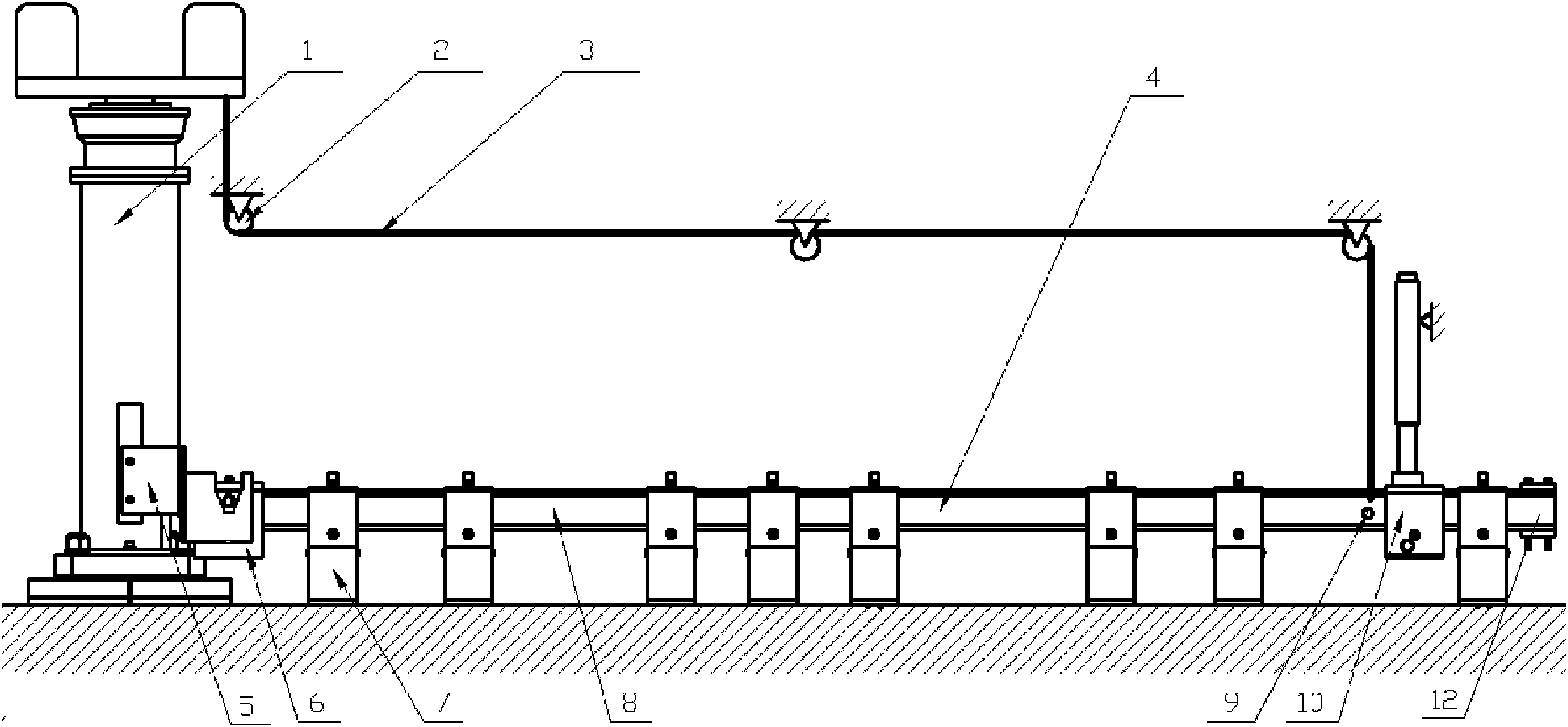

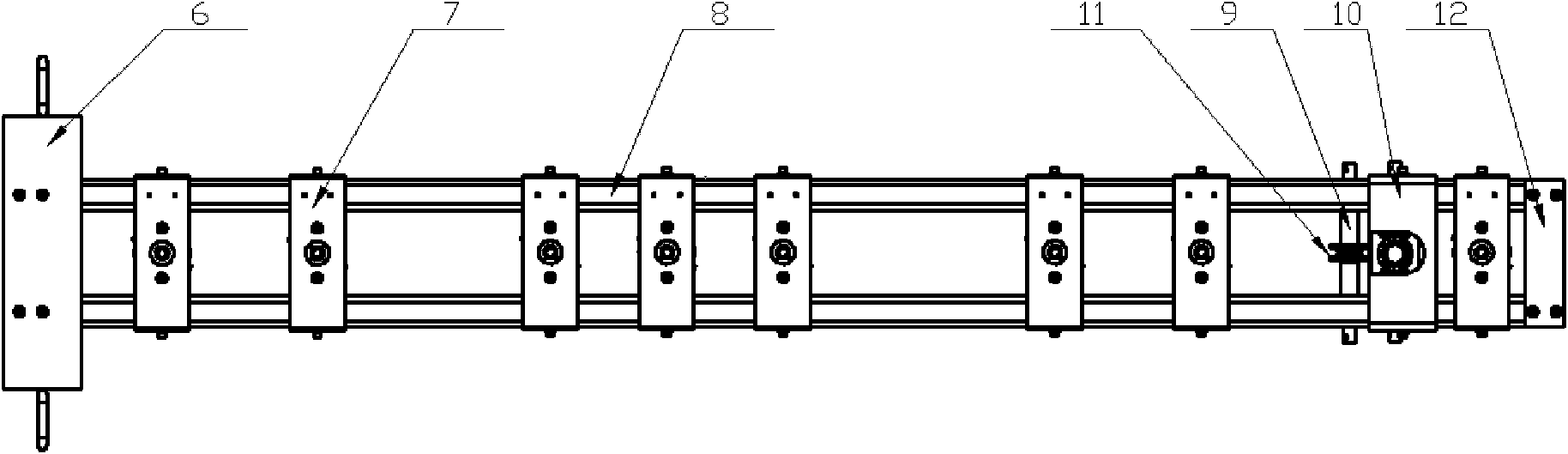

[0018] Such as Figure 1~5 As shown, the multi-point sensor drop-weight deflection meter includes a bearing device 1, a sensor beam 4, a deflection sensor 7 and a guiding mechanism 10. The bearing device 1 is a drop-weight deflection device that bears the impact of a heavy hammer and The impact is transmitted to the road surface to measure the impact force and maximum deflection at the same time. The lower end of the bearing device 1 is fixedly installed with a hook 5, and the part of the hook 5 extending out of the bearing device 1 is two parallel to each other, with " V"-shaped gap plate structure. The sensor beam 4 includes a beam 8, a hook welding assembly 6, a wire rope adjusting shaft 9, a guide mechanism 10, a fixed pulley 11, and a counterweight 12. The left ends of the two parallel beams 8 are fixedly connected to the hook welding assembly 6. The rod-shaped struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com