Water control valve seat structure with induction and manual mixed water outlet functions

A manual mixing and automatic water outlet technology, applied in the directions of sliding valves, engine components, valve operation/release devices, etc., can solve the problems of inability to carry out induction faucets, mixing adjustment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

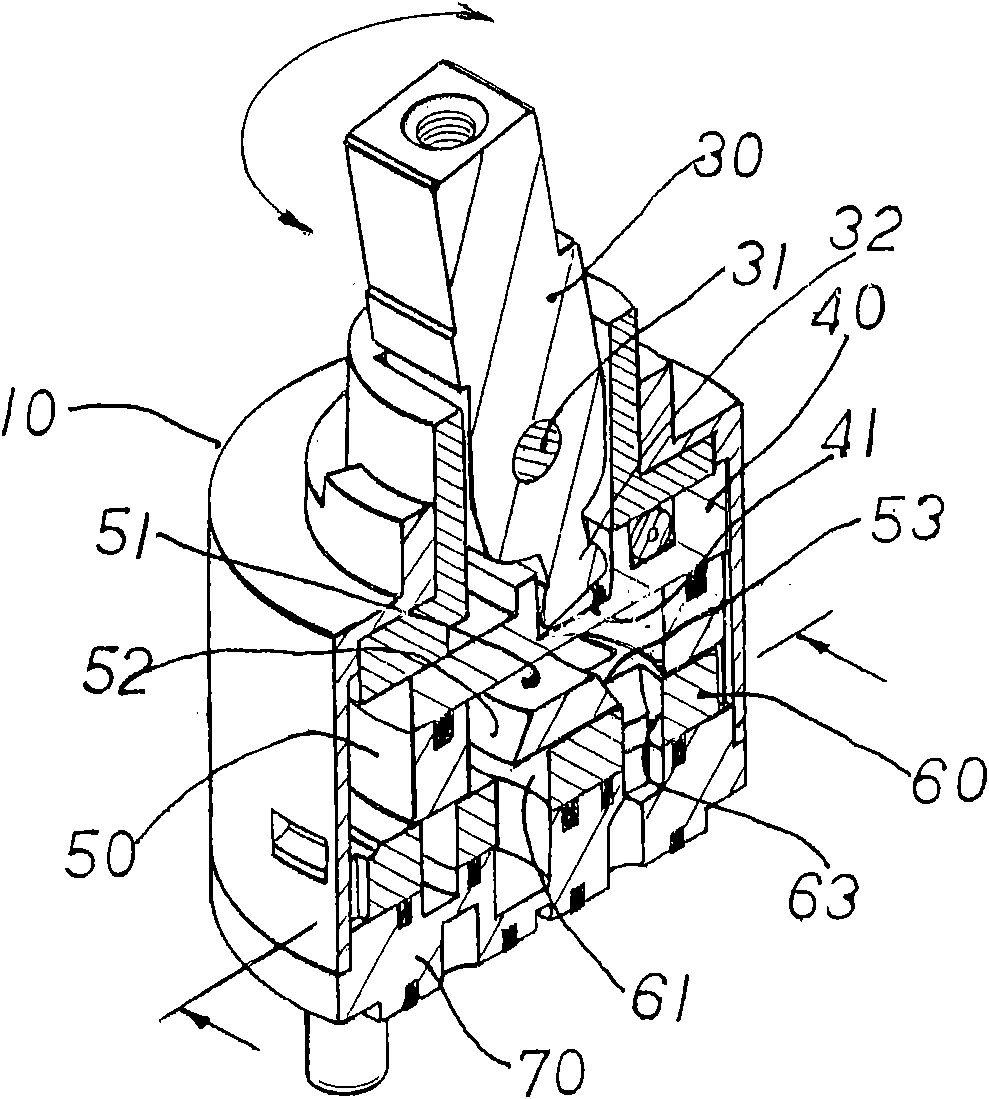

[0034] All the rest, hereby enumerate a specific embodiment in conjunction with the drawings, introduce the structure content of the present invention in detail, and the functional benefits that can be achieved are as follows;

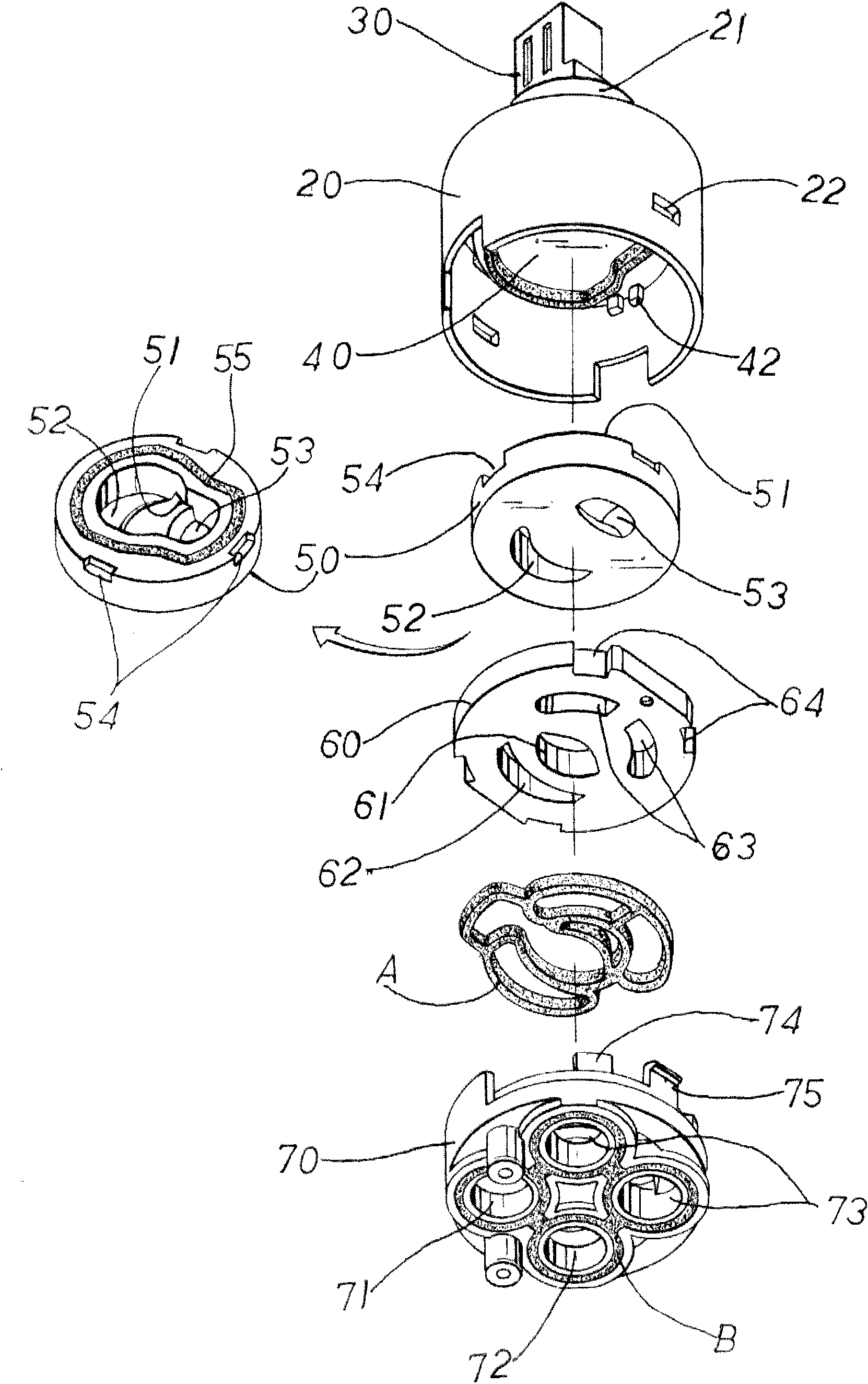

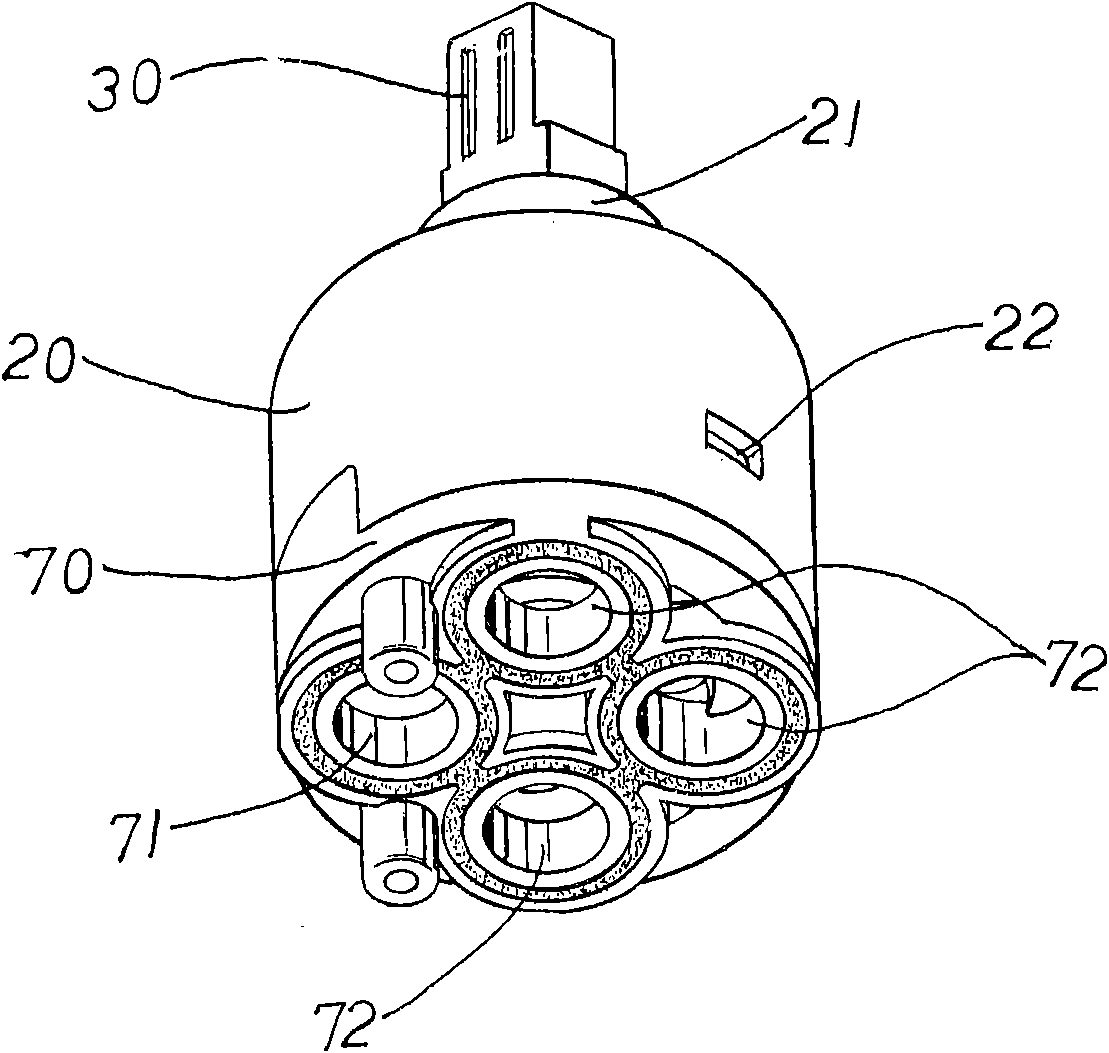

[0035] Such as figure 1 , image 3 As shown, it consists of a control rod 30, a driving member 40, a ceramic moving piece 50, a ceramic static piece 60 and a bottom cover 70 etc. which are sequentially nested in a cylindrical housing 20, wherein;

[0036] The cylindrical housing 20 has a small-diameter opening 21 at the upper end to provide the pivot joint of the control rod 30 , and a button hole 22 opposite to the bottom cover 70 is carved in the lower end of the cylindrical shell.

[0037] The control rod 30 is a rod body with a square cross-section, and is pivotally connected to the small diameter opening 21 of the cylindrical shell base 20 with the middle section transversely passing through the pivot shaft 31 , so that the lower narrow end 32 ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com