Centrifugal type volumetric pump

A positive displacement pump, centrifugal technology, used in rotary piston pumps, pumps, rotary piston machines, etc., can solve problems such as poor sealing, affecting pump efficiency, and excessive wear of vanes and pump casings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

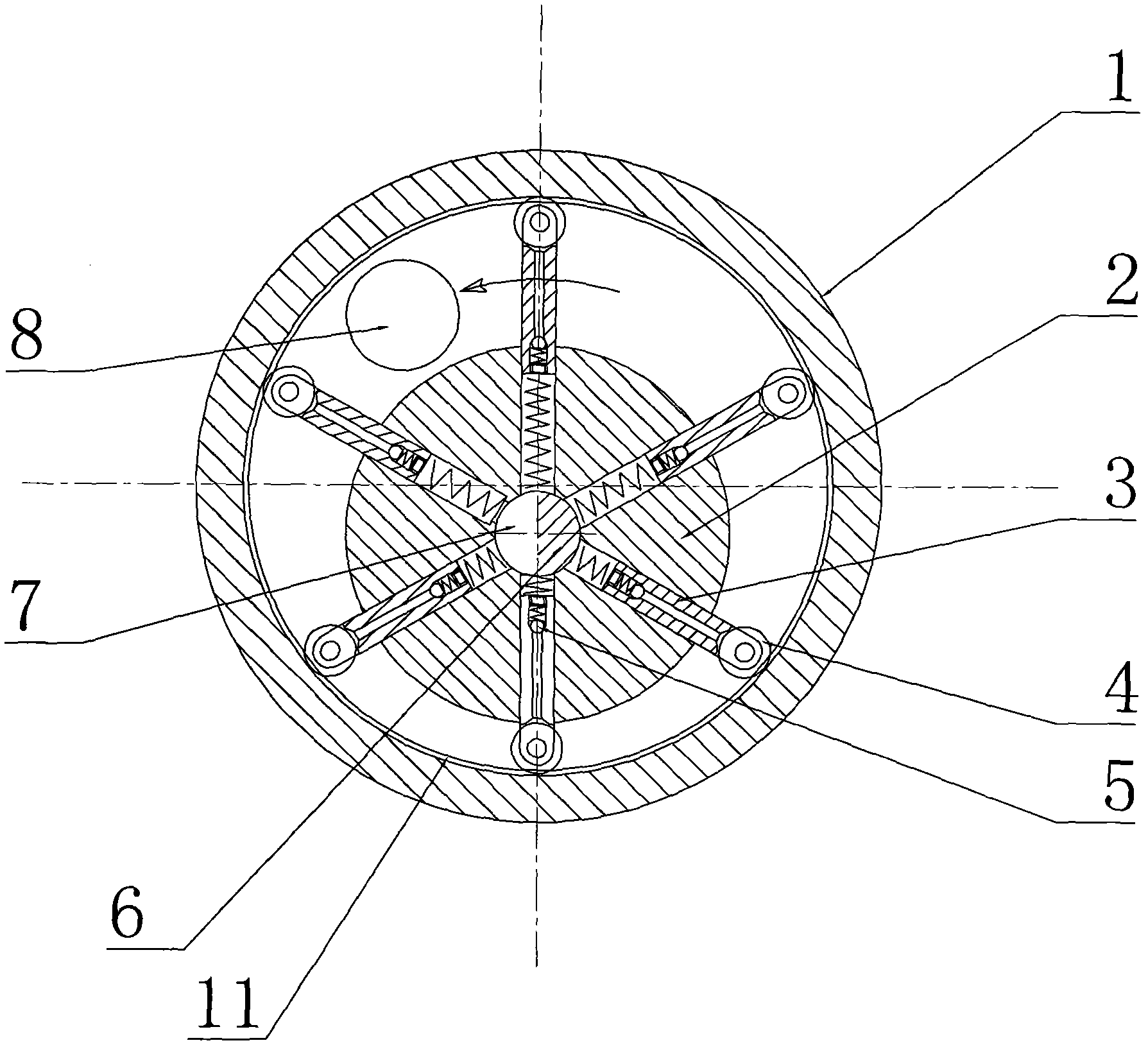

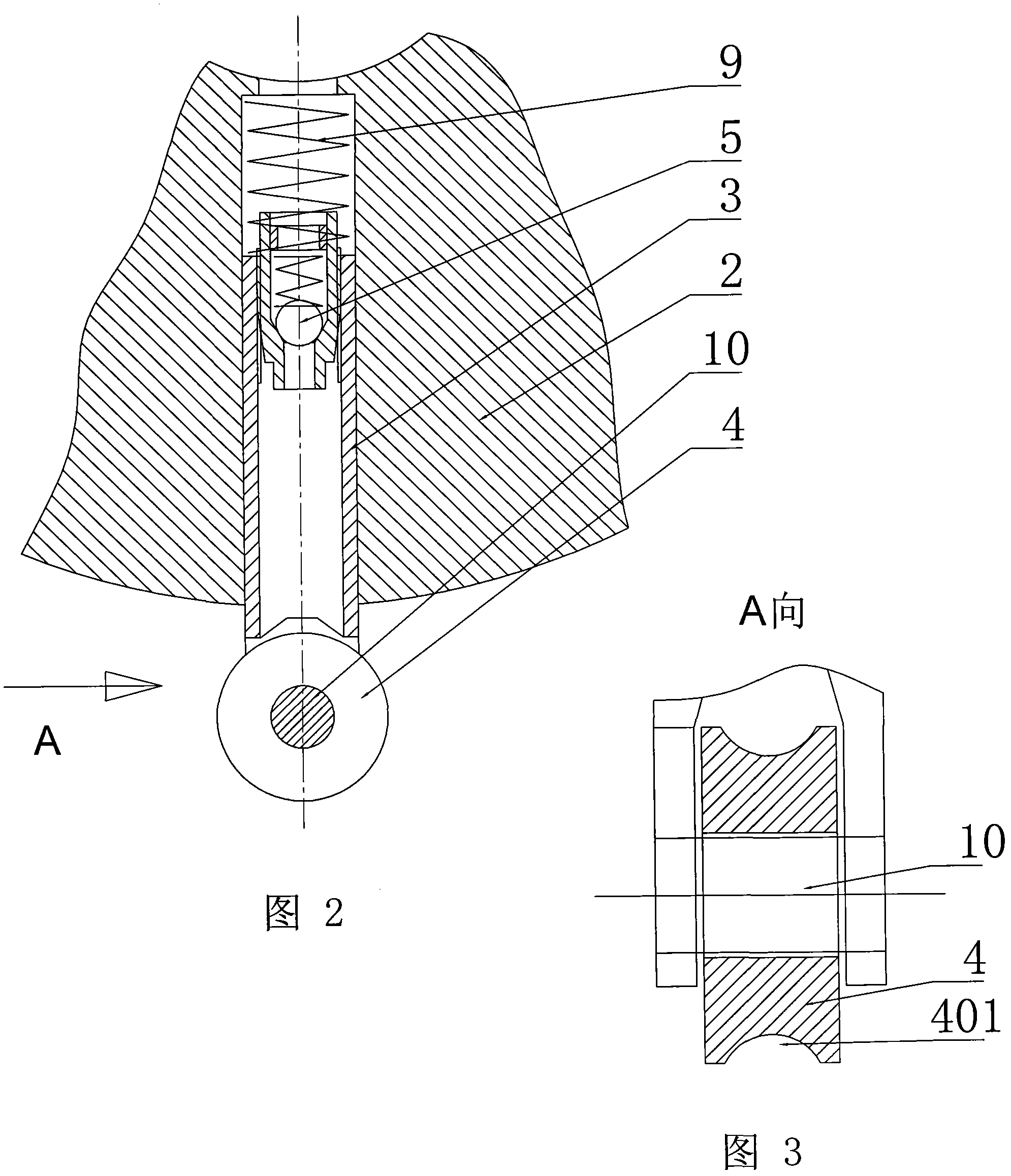

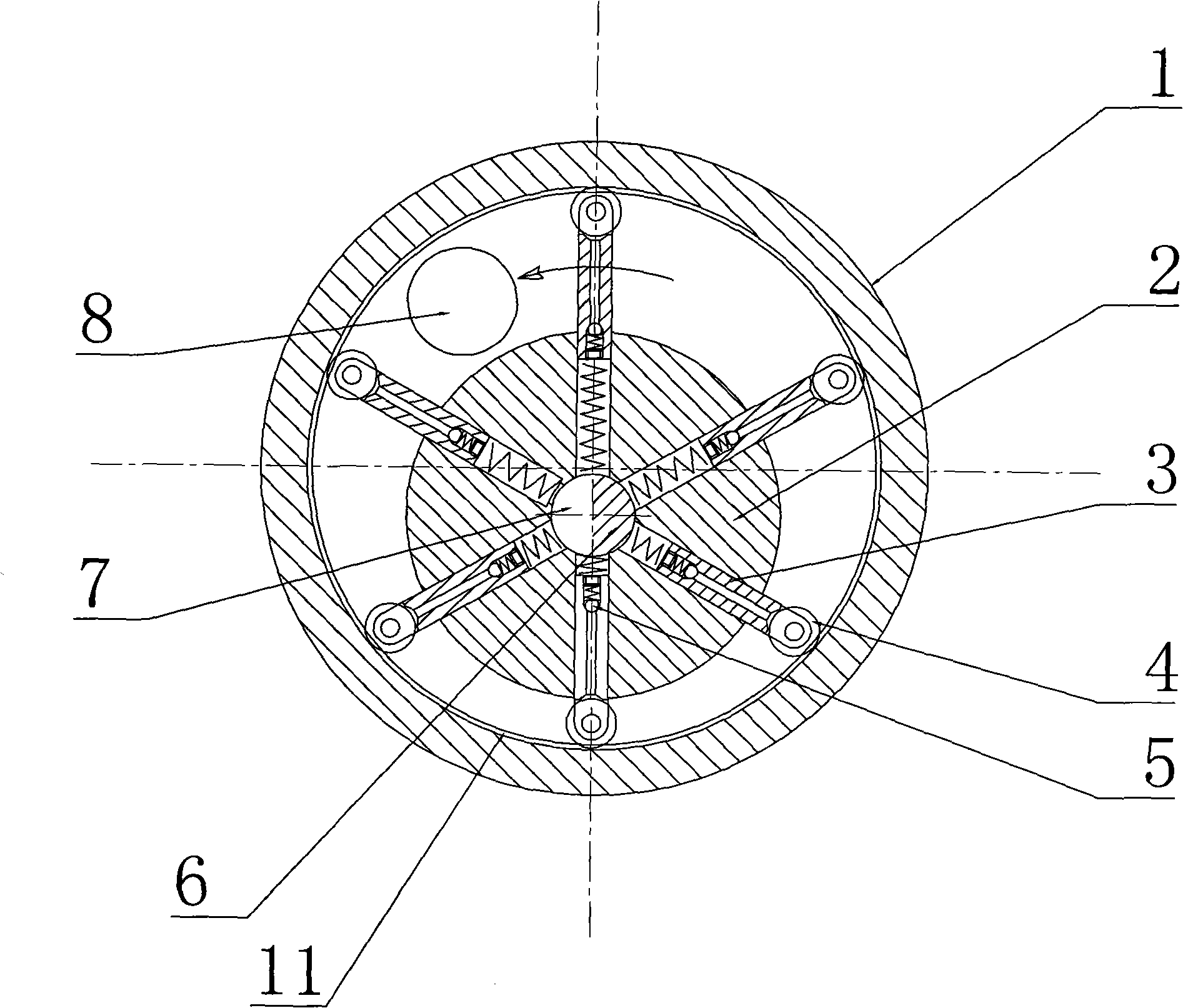

[0011] As shown in Figures 1-3, it is a centrifugal volumetric pump, the inner wall of the pump casing 1 is provided with a guide rail 11, the inner side of the pump casing 1 is a cylindrical pump cavity, and the rotor 2 is eccentrically arranged in the pump casing; 1 Both ends are provided with end covers that close the pump cavity, one of the end covers is provided with an oil inlet 8, and the rotor 2 is evenly opened with a number of radial holes in the circumferential direction, and a plunger 3 is inserted into the radial hole, and the plunger 3 is inserted into the radial hole. 3 A roller 4 is provided at the end of the pump chamber, and a groove 401 is provided on the roller 4. The guide rail 11 is installed in cooperation with the groove 401. The mating surface of the two is arc-shaped. The axial oil outlet hole 7 connected to the hole, the plunger 3 is provided with an axial through hole, the axial through hole is provided with a check valve 5, and the axial oil outlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com