Butt joint device and butt joint method for building fireproof door walls

A technology for docking devices and door walls, which can be used in buildings, building structures, window sills/thresholds, etc., and can solve problems such as overall unevenness, inability to guarantee the safety of the wafer, and damage to the wafer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

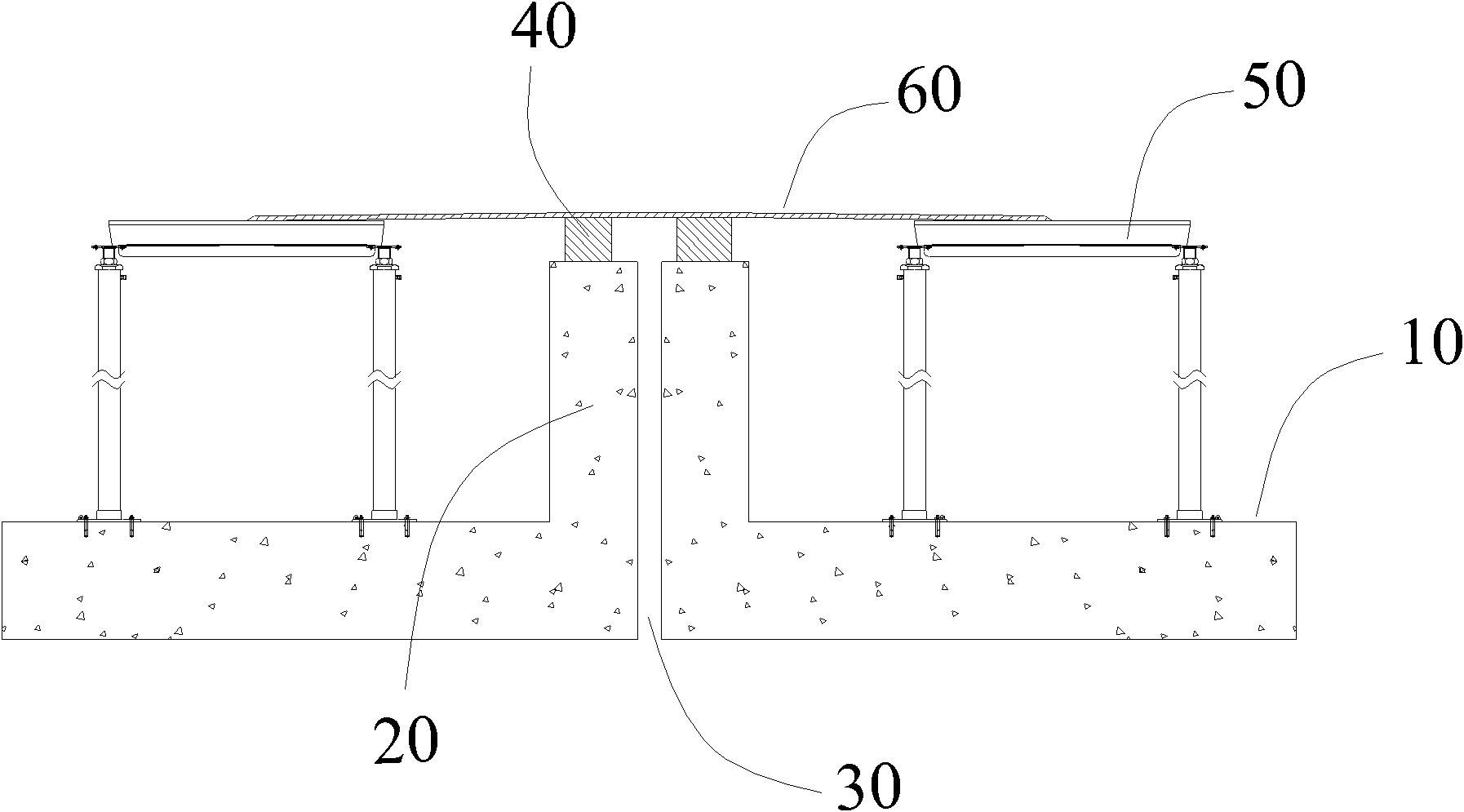

[0023] When the docking device is installed, in some cases, the thresholds erected on the fire door walls of two adjacent buildings may first be processed to reduce the height of the thresholds so that the height of the processed thresholds is lower than the height of the installed raised floor, so that the docking The device can be erected on the building fire door wall and docked horizontally with the installed raised floor.

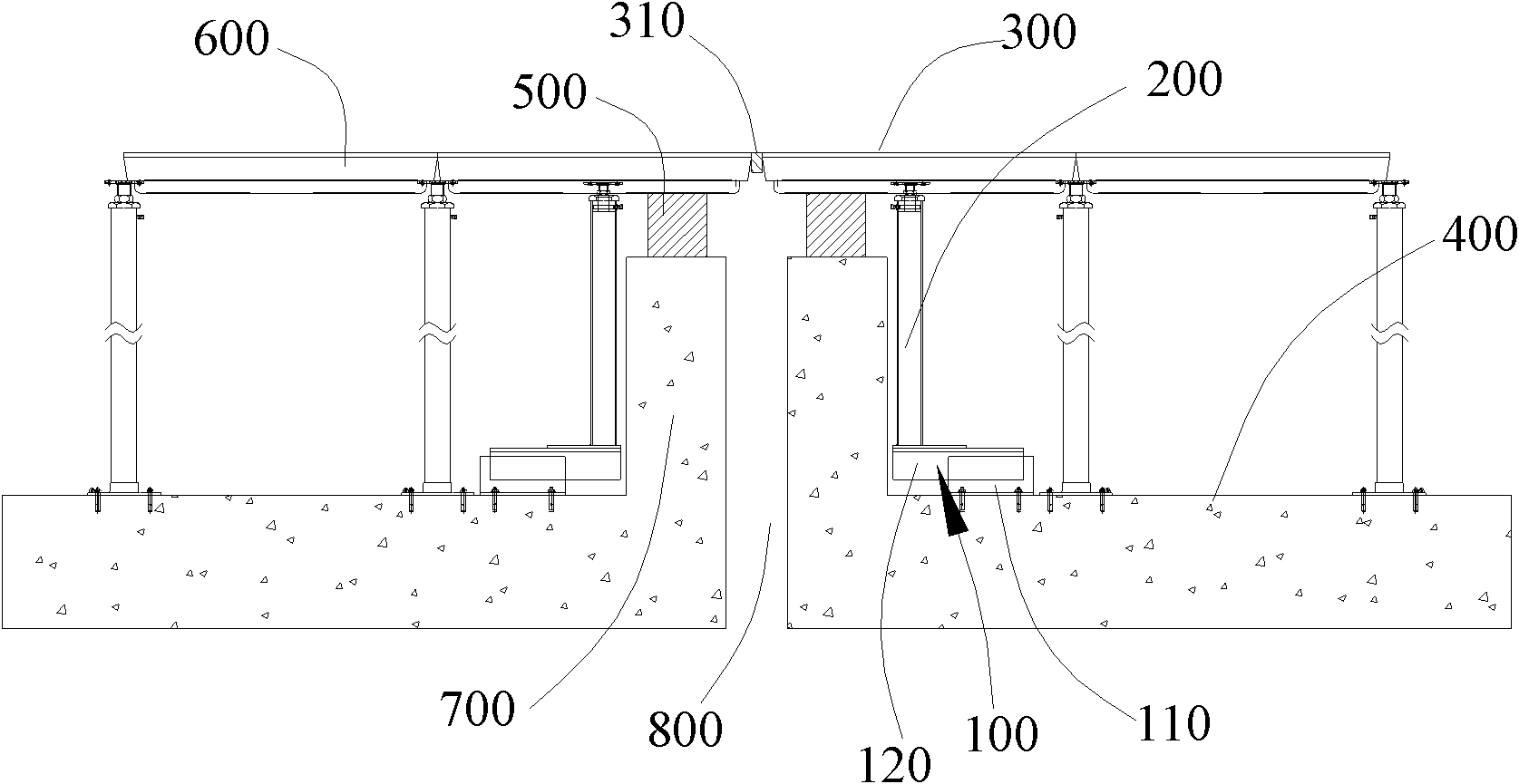

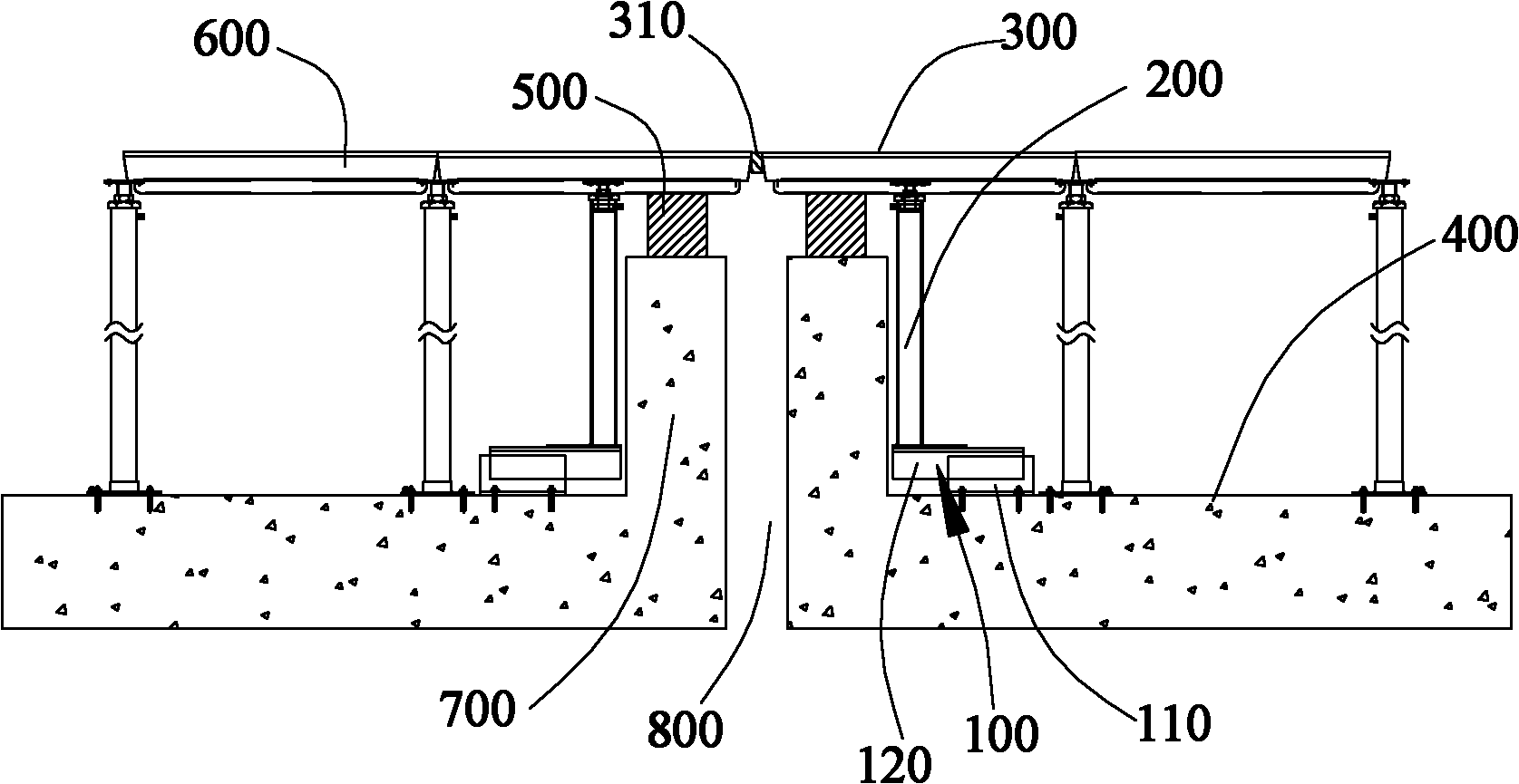

[0024] figure 2 It is a structural schematic diagram of a docking device for a building fire door wall in an embodiment. There are two sets of docking devices, which are located on both sides of the expansion joint 800 and between the building fire door wall 700 and the installed raised floor 600 . The floor support leg assembly 100 and the floor support column 200 form a supporting mechanism for supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com