Preparing system and method of sodium hypochlorite

A manufacturing system, sodium hypochlorite technology, applied in the electrolysis process, diaphragm, electrolysis components, etc., can solve the problems of low operating efficiency of the electrolytic cell, low concentration of available chlorine, high AC power consumption, etc., to avoid the danger of transportation and storage, and the effective chlorine The effect of high concentration and long electrode life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

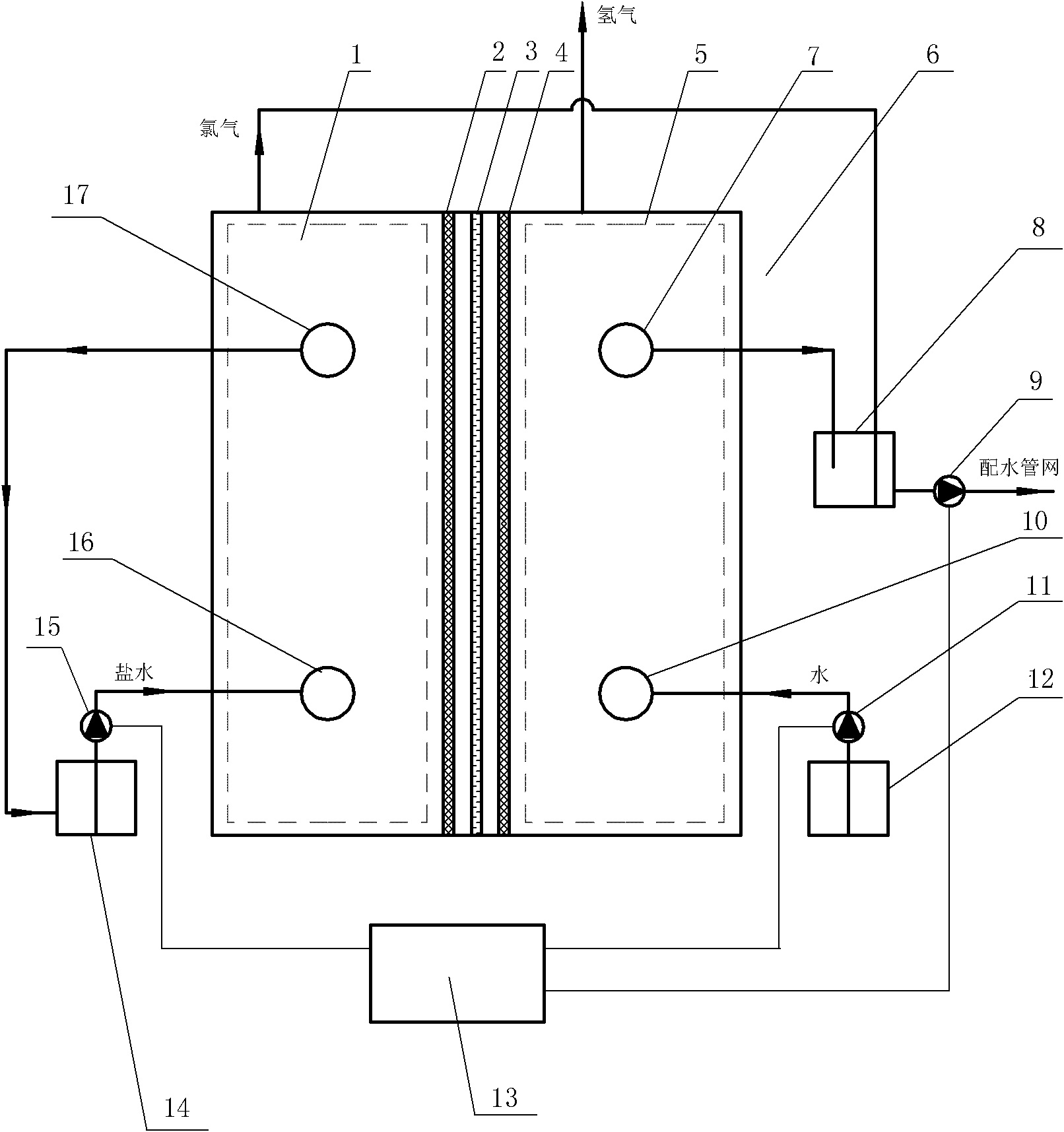

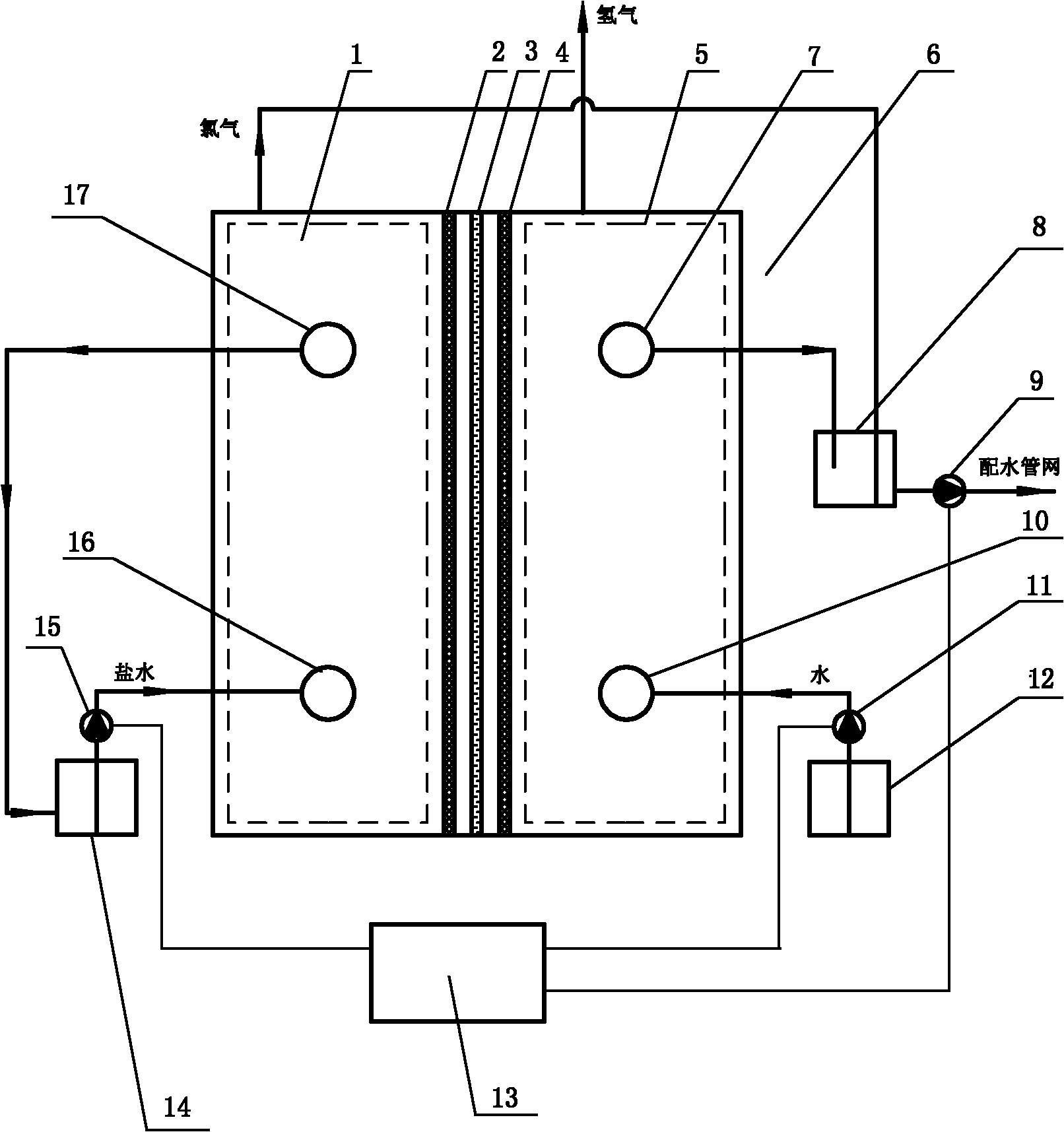

[0020] Such as figure 1 As shown, the label 1 is the anode chamber; the label 2 is the anode; the label 3 is the cationic membrane; the label 4 is the cathode; the label 5 is the cathode chamber; the label 6 is the electrolytic cell; the label 7 is the water outlet; the label 8 is the reaction box; 9 is the dosing pump; the number 10 is the water inlet; the number 11 is the water inlet pump; the number 12 is the water inlet tank; the number 13 is the electric control device; Salt water inlet; Label 17 is salt water outlet.

[0021] refer to figure 1 , The sodium hypochlorite preparation system of the present invention includes: electrolytic cell 6, anode 2, cathode 4, cationic membrane 3, brine circulation dosing box 15, water inlet box 12 and reaction box 8. The anode 2 and the cathode 4 are installed in the electrolytic cell 6 and the electrolytic cell 6 is divided into an anode chamber 1 and a cathode chamber 5, and a cationic membrane 3 is installed between the anode 2 a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com