Four-rod-crossing amplitude compensation device

A compensating device and cross-arm technology, applied in cranes and other directions, can solve the problems of affecting the speed of loading and unloading, large starting and braking inertial force, and large mass of the boom system, achieving short braking time, short guide rail size, and energy saving. consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

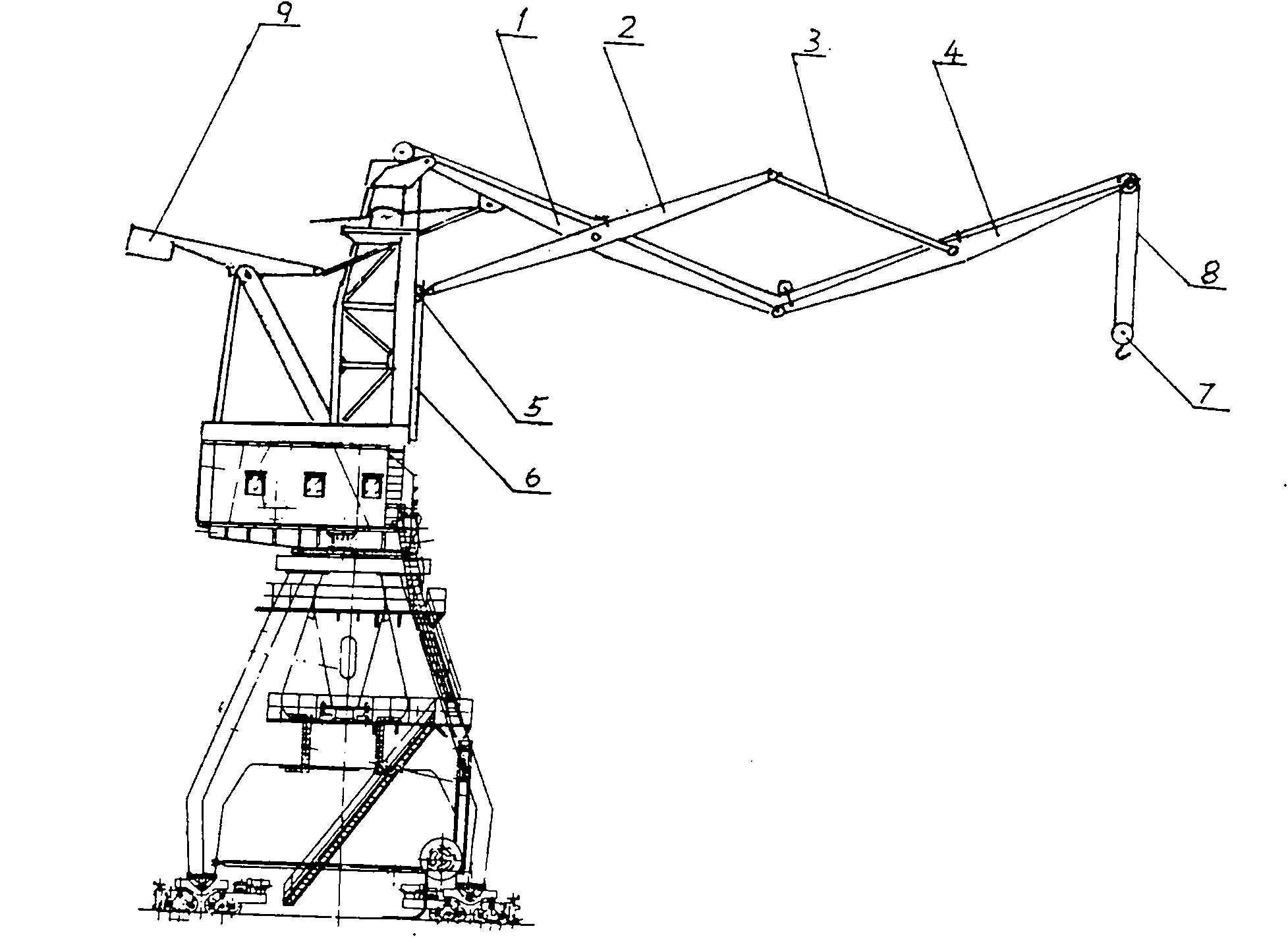

[0022] figure 1 A vertical metal frame is fixed on the slewing platform of the portal crane, the vertical guide rail is fixed in front of the frame, the rear arm 1 of the four-bar cross luffing compensation device is hinged to the top of the frame, and the guide wheel 5 at the lower end of the cross arm 2 can roll up and down along the vertical guide rail 6 , The driving mechanism drives the rear arm to swing, so that the spreader can move horizontally. The balance of the gravity of the boom system is balanced by the counterweight 9. Compared with similar products, the height of this machine can be lowered by 15m.

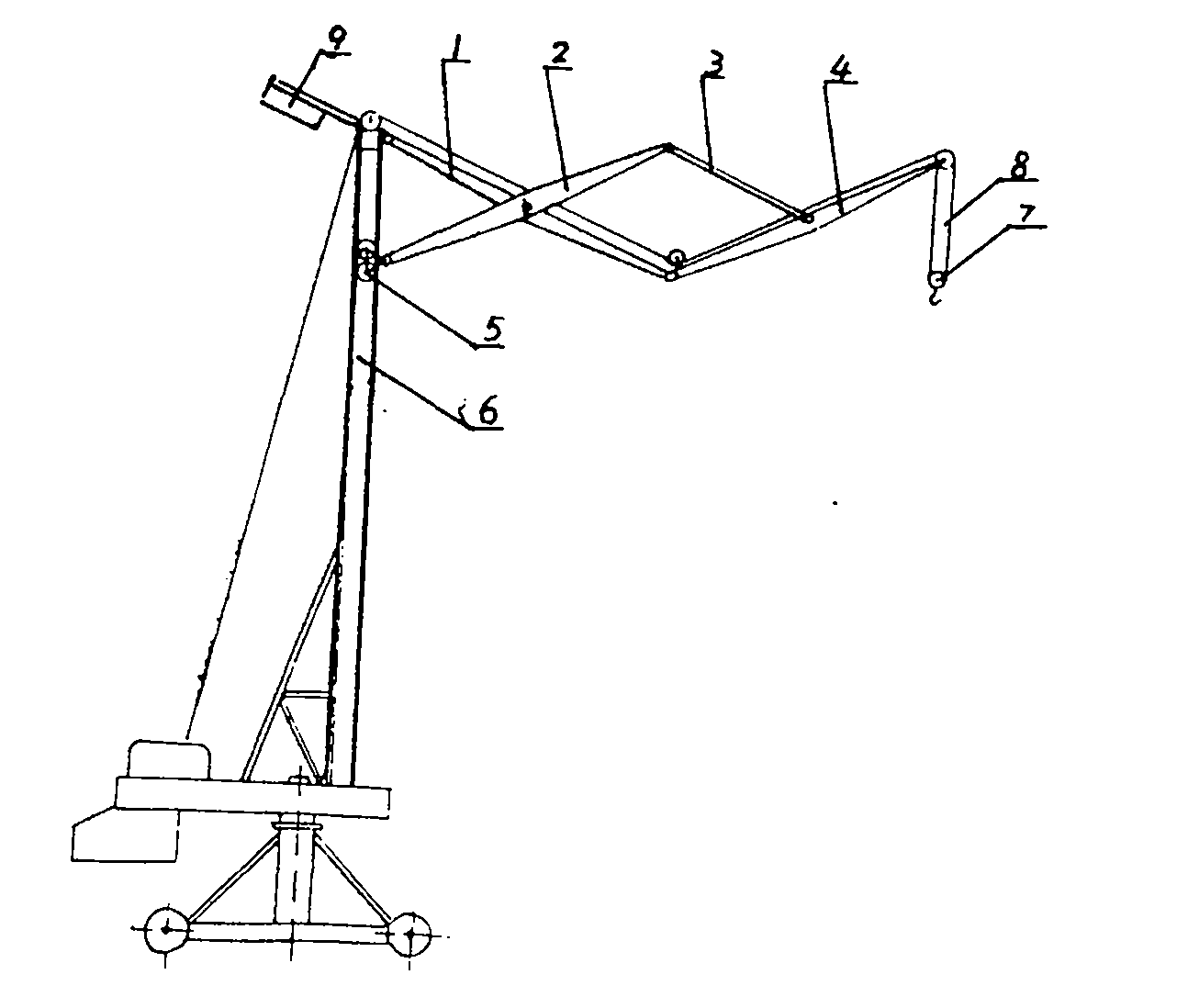

[0023] exist figure 2 For the medium and small-sized cranes, the channel steel is used to form the vertical guide rail 6, and the guide wheel 5 rolls up and down along the inner flange of the channel steel. Therefore, manpower is used to pull the goods to achieve variable amplitude.

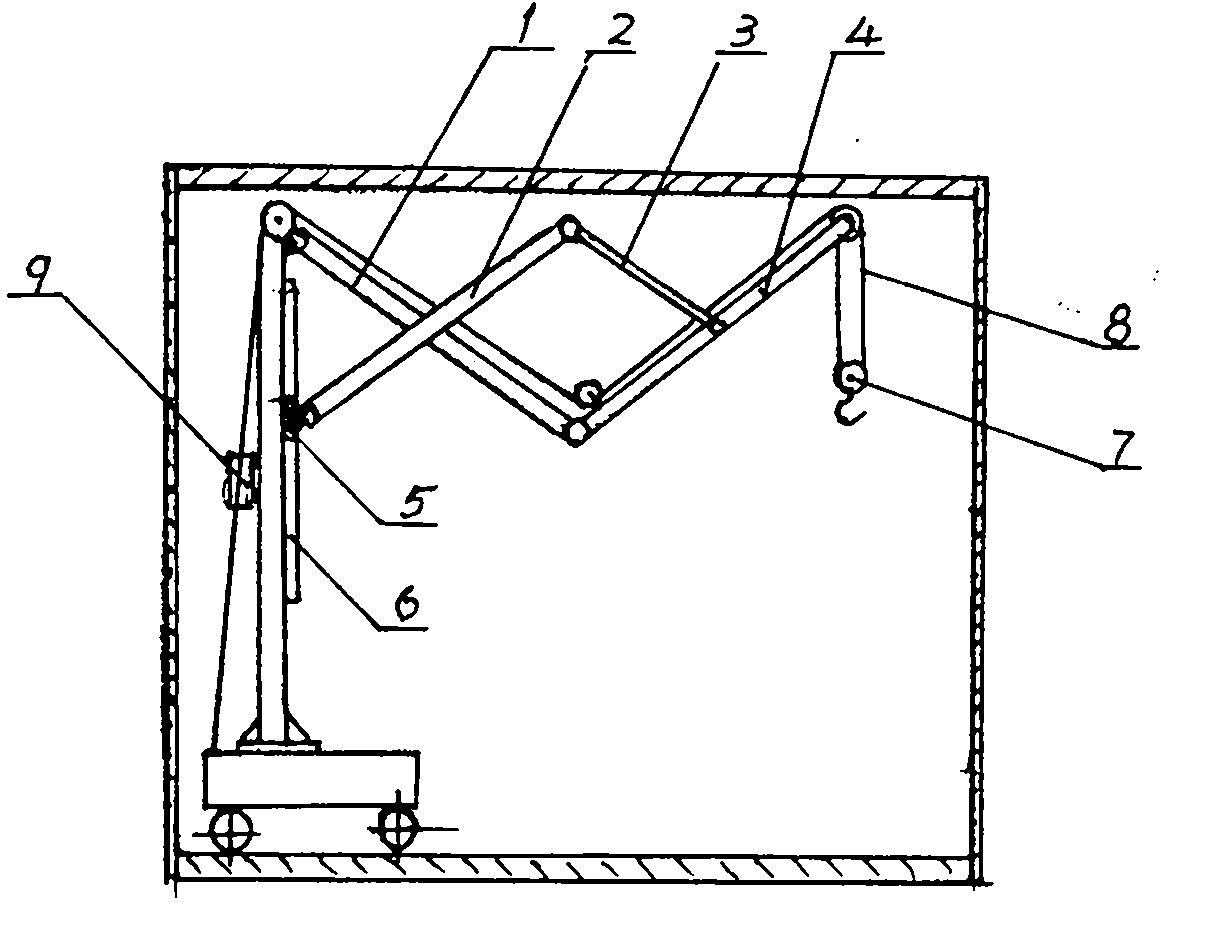

[0024] image 3 It is a schematic diagram of loading and unloading operations...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com