Semi-automatic motor vehicle unloading and lifting device

A motor vehicle, semi-automatic technology, applied in the directions of transportation and packaging, load hanging components, etc., can solve the problems of not achieving satisfactory results, affecting the appearance quality, wasting raw materials, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

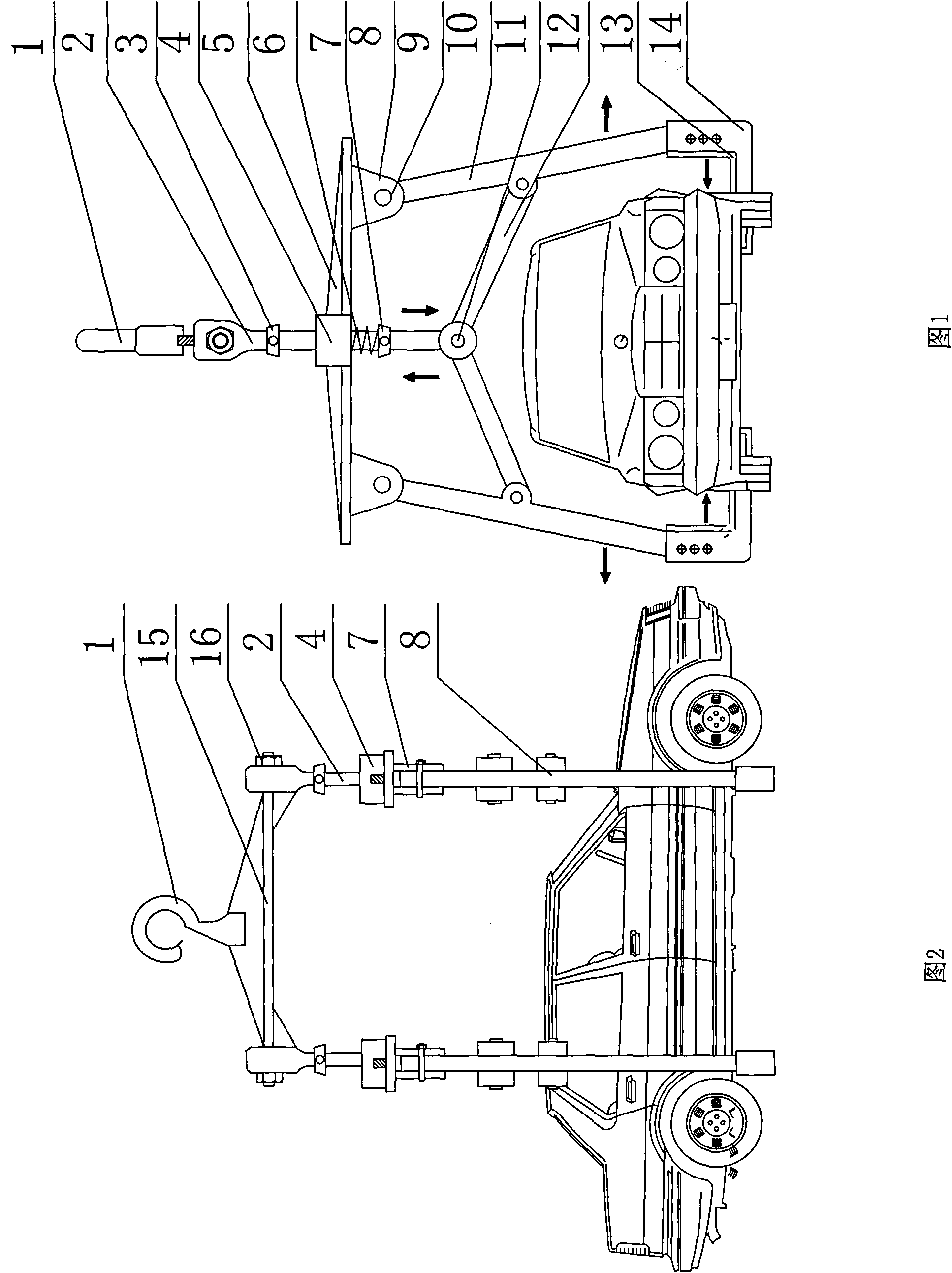

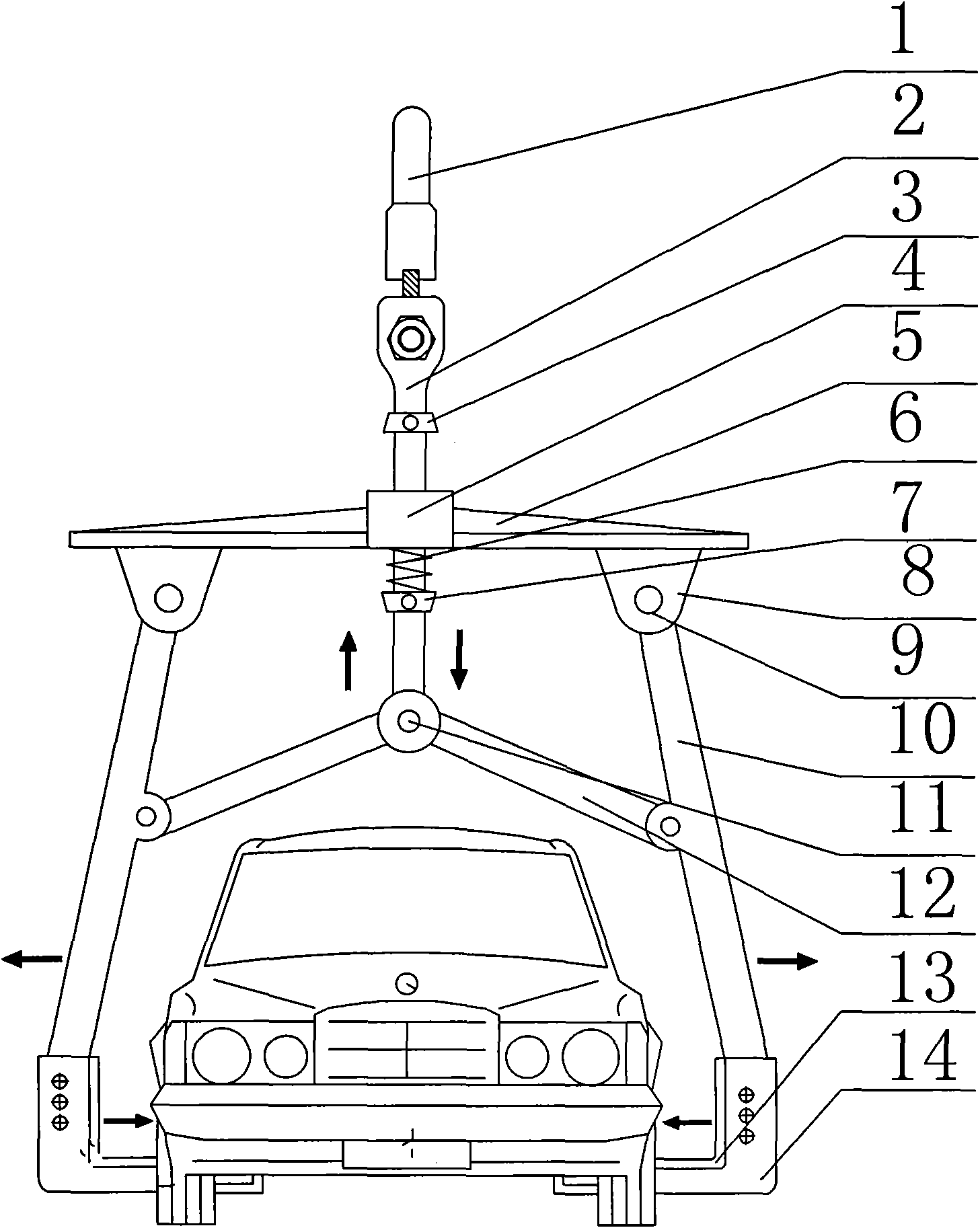

[0011] exist figure 1 , figure 2 Middle: The hook 1 is set at the center of the reinforcing rib of the large hanger 15, the large hanger 15 is welded by round steel and triangular reinforcing ribs, the two top ends of the round steel of the large hanger 15 are provided with bolts, the upper end of the movable rod 2 The holes are connected with the bolts on the large hanger 15, and the bolts are fixed by nuts 16. The small hanger 5 is a frame of a rectangular steel plate structure, and the upper center of the small hanger 5 is provided with a guide sleeve 4. The two ends of the small hanger 5 are welded with triangular steel reinforcing ribs, and a connecting ear 8 is respectively provided at the two ends of the small hanger 5, and the connecting ear 8 is provided with pin shaft 9 holes. The holes coincide with each other, and they are connected with the pin shaft 9. The middle end of the large support arm 10 stretches out a lug, and the hole on the lug coincides with the hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com