Four-way positioning system of distributing vehicle

A positioning system and material truck technology, applied in conveyors, mechanical conveyors, transportation and packaging, etc., can solve problems such as left and right swings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

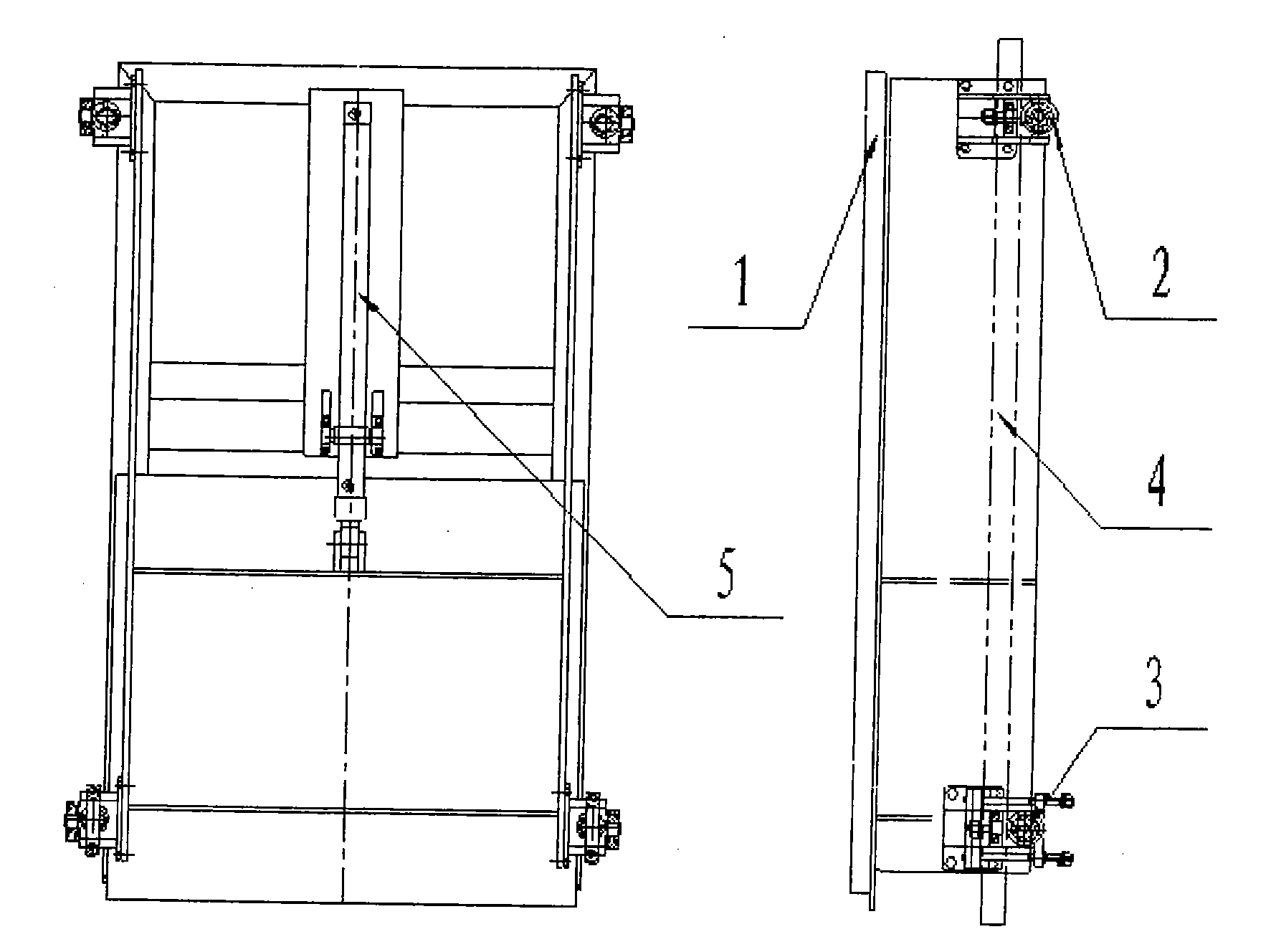

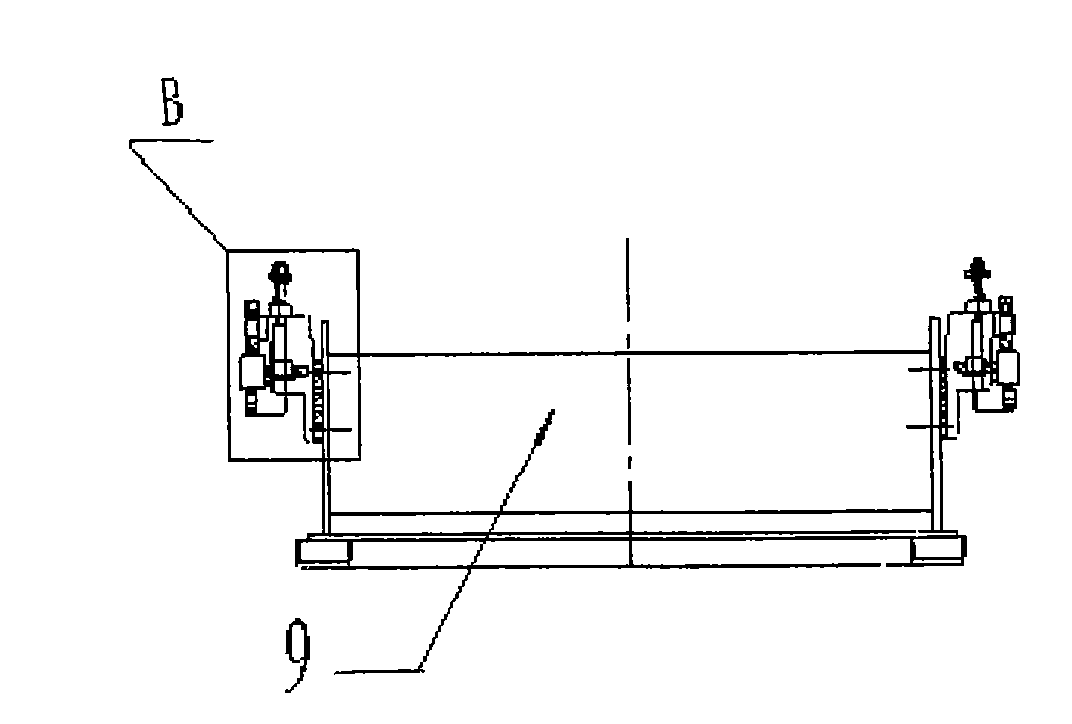

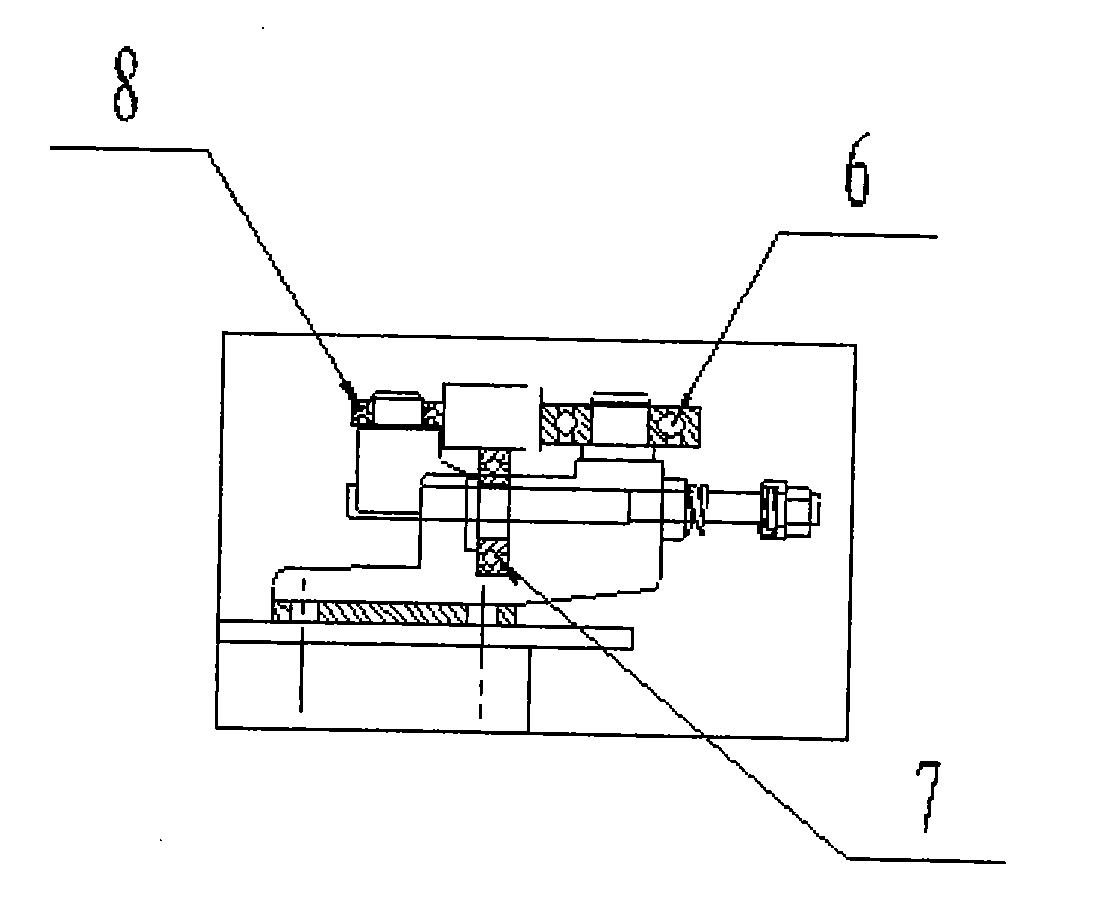

[0012] As shown in the figure: a four-way positioning system for a material truck, consisting of a material vehicle chassis 1, a silo rear positioning wheel 2, a material silo front positioning wheel 3, a track 4 and an oil cylinder 5; it is fixed on both sides of the material vehicle chassis There are tracks on which the front positioning wheel of the silo and the rear positioning wheel of the silo are respectively installed. The positioning wheel is composed of three bearings: the upper bearing 6, the side bearing 7 and the lower bearing 8; the ash bucket 9 is installed between the two side tracks, The oil cylinder is connected with the ash hopper. The installation shafts of the bearings on the front and rear positioning wheels of the above-mentioned hopper are all eccentric structures, and the fit clearance between the outer ring of the bearing and the track can be adjusted at any time. After adjusting the eccentric shaft of the bearing, the positioning size of up, down, lef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com