Hinge for connecting a leaf to a frame so as to be hinged about a hinge axis

A hinge axis and hinge technology, applied in the hinge field, can solve the problems of small electric power and high power loss, and achieve the effect of reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

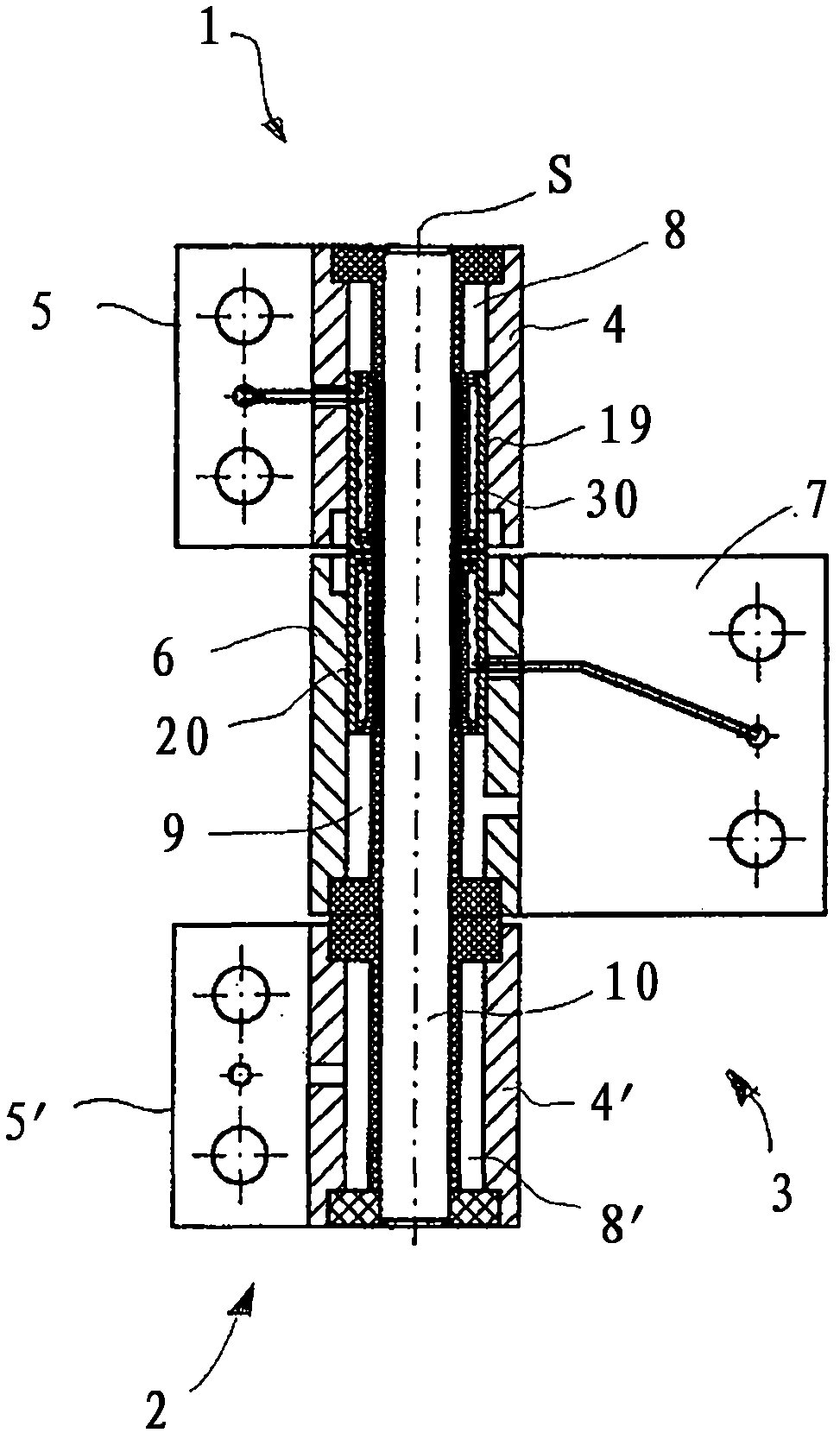

[0027] The hinge, indicated as a whole by 100 in the figures, is designed as a so-called three-part hinge. It comprises an upper frame hinge part 1 and a lower frame hinge part 2 , which are spaced apart from each other in the longitudinal direction of the hinge axis S. FIG.

[0028] A leaf hinge 3 is arranged between the upper frame hinge 1 and the lower frame hinge 2 .

[0029] The upper frame hinge part and the lower frame hinge part 1, 2 respectively comprise a frame hinge part 4, 4' and a frame fixing part 5, 5'. Correspondingly, the leaf hinge includes a leaf hinge part 6 and a leaf fixing part 7 .

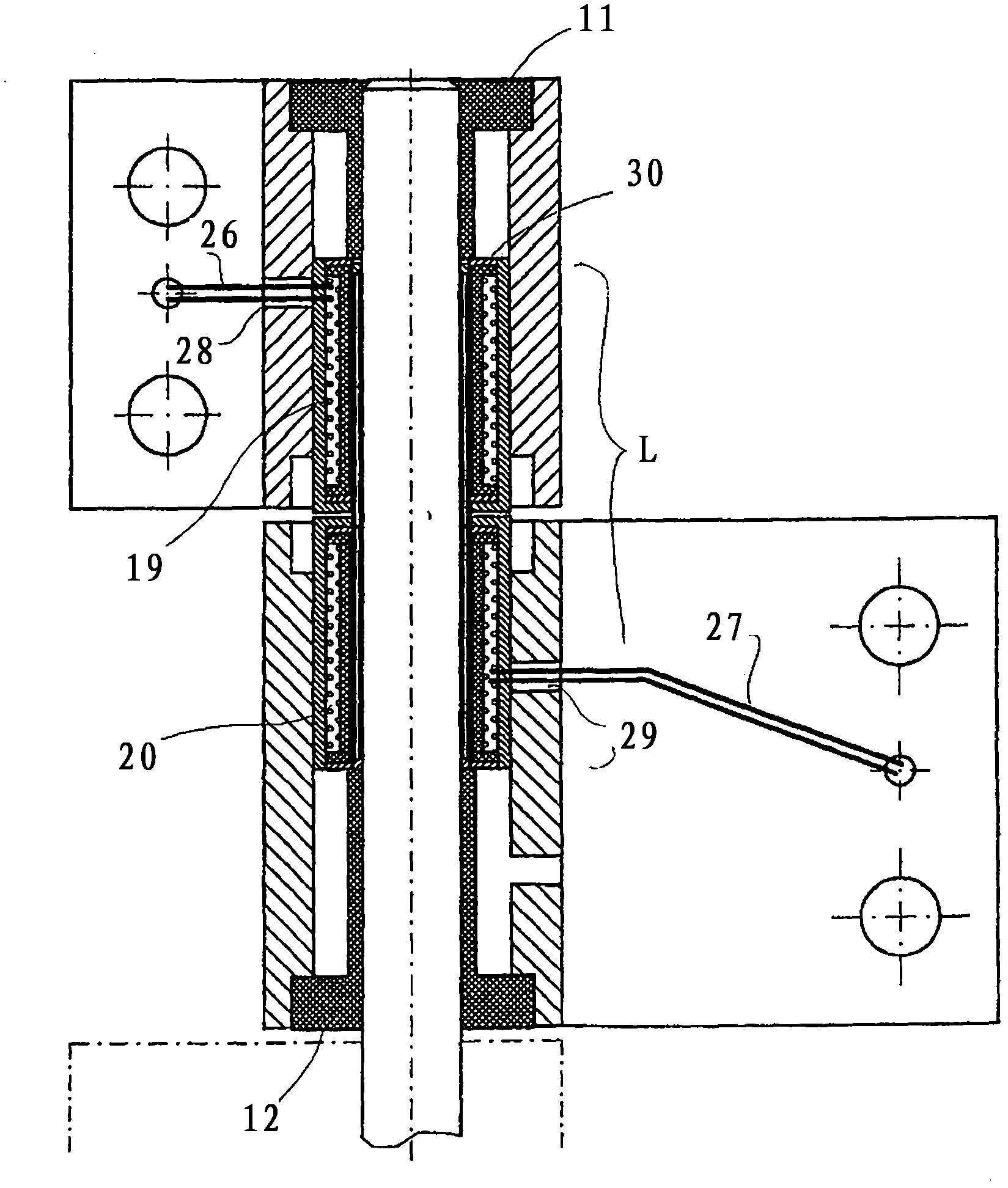

[0030]The hinge axis S is defined by the hinge pin 10 passing through the frame hinge parts 4 , 4 and the leaf hinge part 6 in the hinge pin receptacles 8 , 8 ′ and 9 . Bearing sleeves 11 , 11 ′ and 12 made of plastic material, eg POM-based plastic material with sliding bearing-modified additives, serve to support the hinge pin 10 in the hinge pin receptacle 8 , 8 ′, 9 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com