Laser gain module and liquid cooling circulating device used for same

A technology of laser gain and circulation device, applied in lasers, laser parts, phonon exciters, etc., can solve the problems of laser crystal rod jitter, laser rod impact, lack of stability of laser radiation, etc., to achieve easy design and installation, Simple structure, high efficiency of liquid cooling and heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Below, the present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

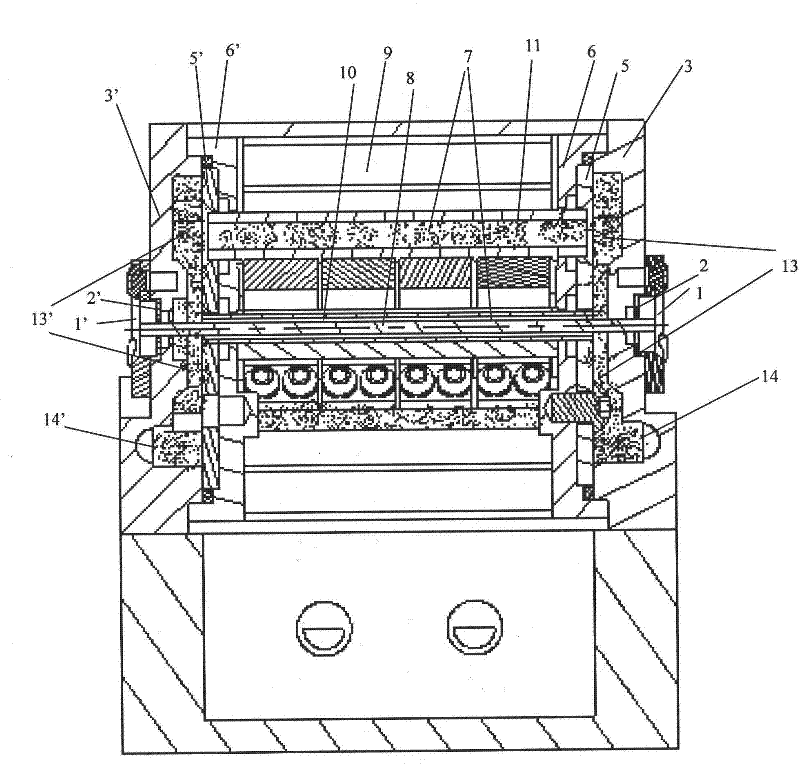

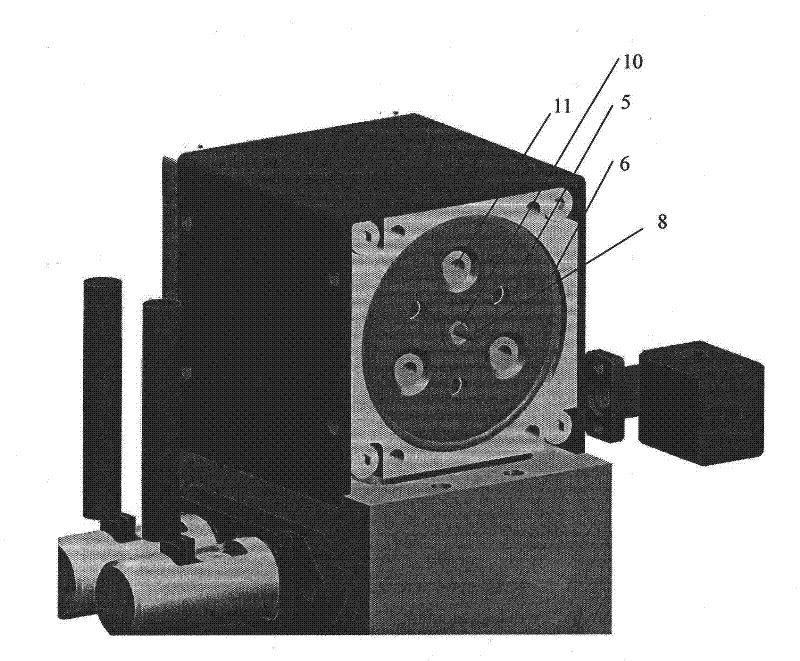

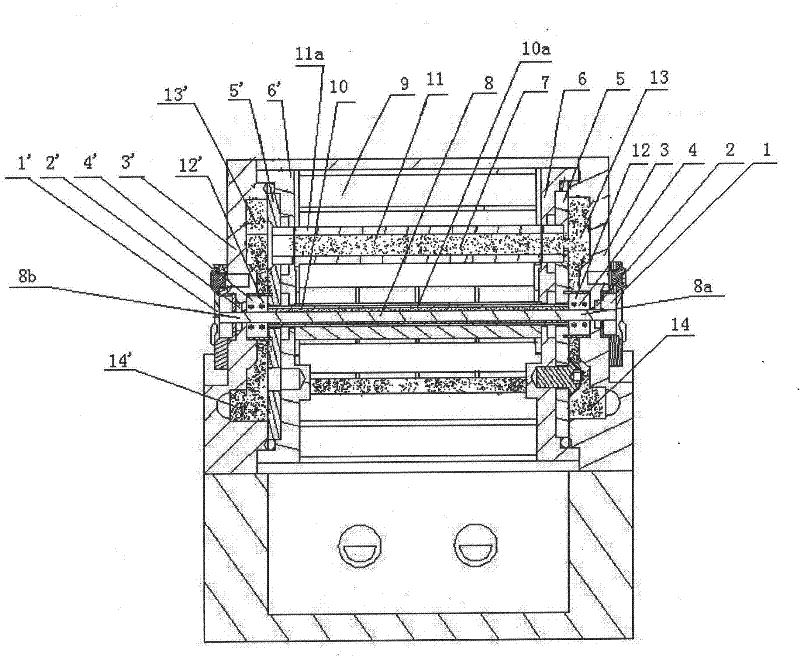

[0049] According to one embodiment of the present invention, a laser gain module is provided. Figure 2A A schematic diagram of the cross section (longitudinal section along the axis of the module body) of the laser gain module is shown, Figure 2B A three-dimensional schematic diagram of the laser gain module of this embodiment is shown. The laser gain module includes a module body 9, a laser crystal rod 8, a pump source ( Figure 2A , Figure 2B Not shown in ) and liquid cooling cycle device. The liquid cooling circulation device includes a cooling liquid circulation channel, a refrigerator and a pumping device ( Figure 2A , Figure 2B Refrigerator and pumping device are not shown in the figure), the cooling liquid circulation channel is composed of built-in cooling liquid input cavity 13, input buffer cavity 12, main cooling cavity 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com