Overhead drawing device for segment colored cotton sliver production and method for segment colored cotton sliver production

A production method and elevated technology, applied in the field of cotton yarn spinning, can solve the problems of high cost and complex mechanism, and achieve the effect of simple structure and easy production control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

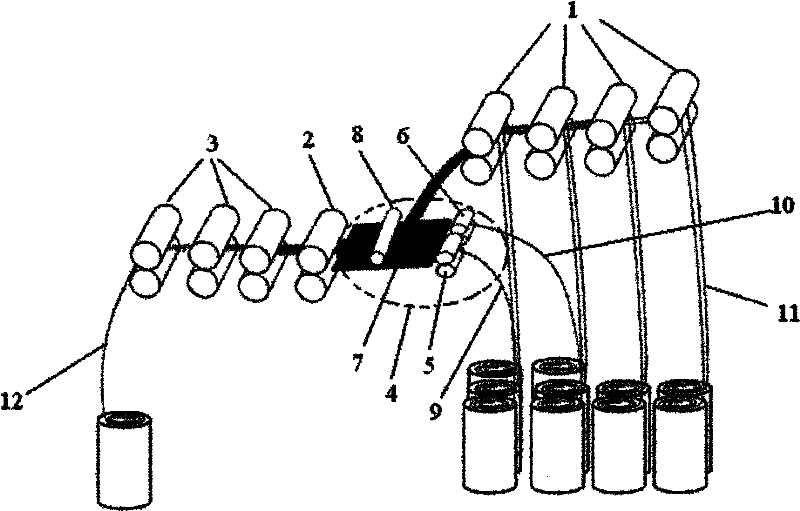

[0031] Such as figure 1 The overhead drawing frame device for colored cotton slivers shown in the production section includes elevated guide rollers 1, feeding rollers 2, and drafting rollers 3 connected in sequence, as well as drawing frame additional device 4 connected with feeding rollers 2 , the drawing frame attachment 4 is located between the feeding roller 2 and the elevated guide roller 1, and is located below the elevated guide roller 1.

[0032] The additional device 4 of the drawing frame includes an additional sliver control component sequentially connected to the feeding roller 2 and two pairs of additional feeding rollers 5, 6 side by side, and the additional sliver control component includes a supporting plate 7 and Adjustable control guide bar 8, the adjustable control guide bar 8 is located on the support plate 7, the upper surface of the support plate 7, the jaw lines of two pairs of additional feeding rollers 5, 6 and The jaw lines of the described feeding ...

Embodiment 2

[0035] Produce three-color colored sliver that meets the following requirements:

[0036] 1. The main sliver is 6 white slivers (the white sliver is also a natural color sliver), and the additional feeding sliver is 1 red sliver and 1 blue sliver.

[0037] 2. The weight of red cotton sliver is 18.0g / 5m, the weight of blue cotton sliver is 18.0g / 5m, and the weight of white cotton sliver is 12.0g / 5m.

[0038] 3. Set the total drafting ratio of the overhead drawing frame device of this embodiment to 6 times.

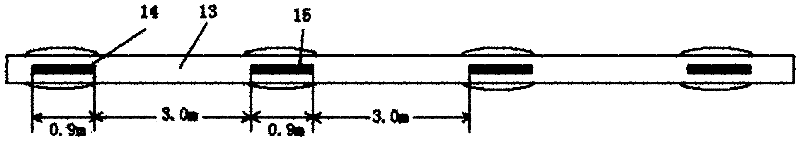

[0039] 4. The three-color lengths of the three-color section colored sliver of the present embodiment are 0.90 meters in red (the red segment 14 formed by feeding the red sliver), and 0.90 meters in blue (the blue segment 15 formed by the feeding of the blue sliver). ), white 3.0 meters (white segment 13 formed by natural color sliver feeding), circulate along the length direction of sliver, such as figure 2 shown.

[0040] 5. The thickness of the sliver of the red and ...

Embodiment 3

[0048] Produce four-color colored sliver that meets the following requirements:

[0049] 1. The main sliver is 6 white slivers (the white sliver is also a natural color sliver), and the additional feeding sliver is 1 red sliver and 1 blue sliver.

[0050] 2. The weight of red cotton sliver is 18.0g / 5m, the weight of blue cotton sliver is 18.0g / 5m, and the weight of white cotton sliver is 12.0g / 5m.

[0051] 3. Set the total drafting ratio of the overhead drawing frame device of this embodiment to 6 times.

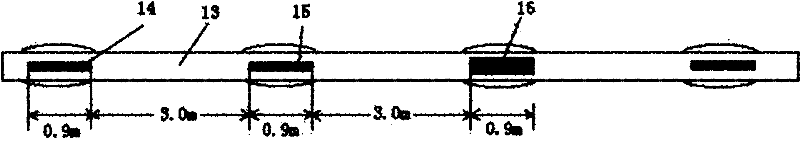

[0052] 4. The four-color segment lengths of the four-color section colored sliver of the present embodiment are 0.90 meters in red (the red segment 14 formed by feeding the red sliver), and 0.90 meters in blue (the blue segment formed by feeding the blue sliver). 15), red and blue mixed color 0.90 meters (red and blue cotton sliver fed into the formed red and blue mixed color segment 16 at the same time), white 3.0 meters (the white segment 13 formed by natural color cotton...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com