Sweater unweaving frame

A wire rack and sweater technology, applied in the direction of conveying filamentous materials, thin material processing, transportation and packaging, etc., can solve the problems of low efficiency and easy occurrence of sweaters, and achieve the effect of improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

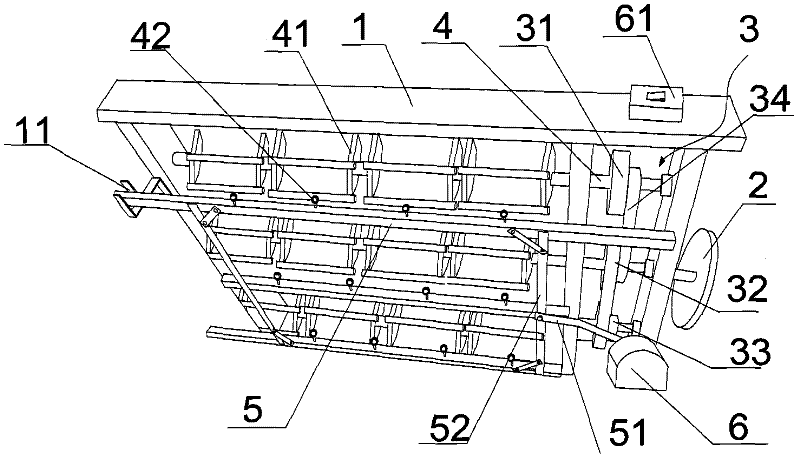

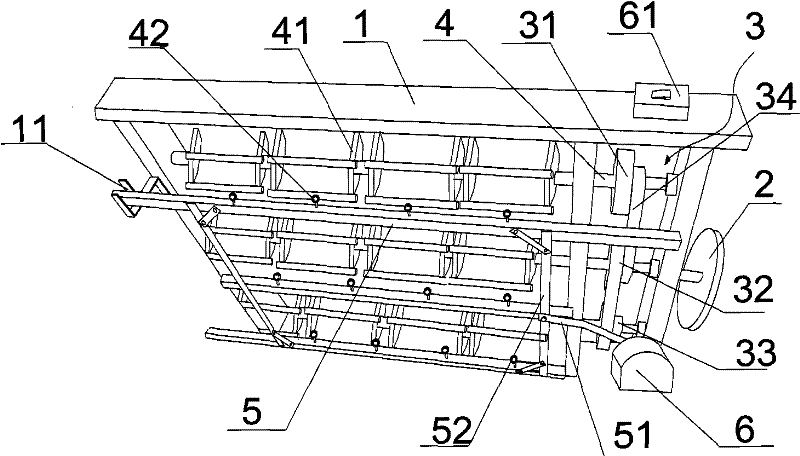

[0017] as attached figure 1 As shown, a sweater thread removal stand, which includes a thread removal stand 1, a main drive turntable 2 rotated on the thread removal stand 1, an auxiliary drive pulley 3 driven by the main drive turntable 2, and an auxiliary drive pulley 3 driven by the turntable Rotate the plurality of rotating shafts 4 arranged on the thread removal rack 1 and the plurality of winding frames 41 fixedly arranged on the rotating shaft 4. One side of the thread removal rack 1 is also provided with a plurality of shafts corresponding to the rotating shaft 4 and capable of sliding horizontally. The support rod 5 is also provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com