Automatic variable diameter chipless cutting machine

A cutting machine and automatic technology, applied in metal processing and other directions, can solve the problem of no automatic variable diameter cutting machine, etc., and achieve the effect of safe and reliable electrical control, simple and convenient operation, and online automation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with specific drawings and specific embodiments.

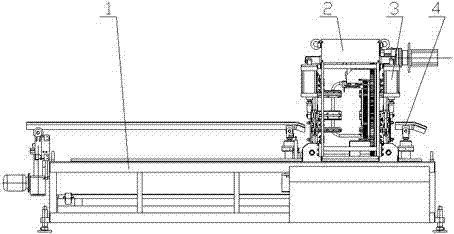

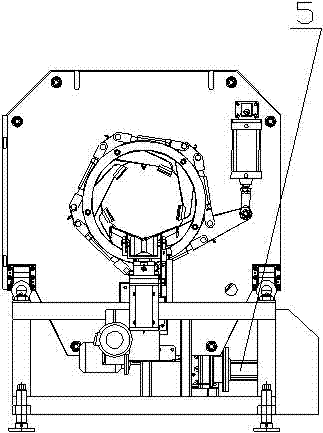

[0029] Such as figure 1 with figure 2 As shown, the present invention is an automatic variable-diameter chipless cutting machine, including a frame 1, a support mechanism 4, a clamping mechanism 3 and a rotating mechanism 2 arranged on the frame 1 in sequence, and a Follow-up mechanism 5.

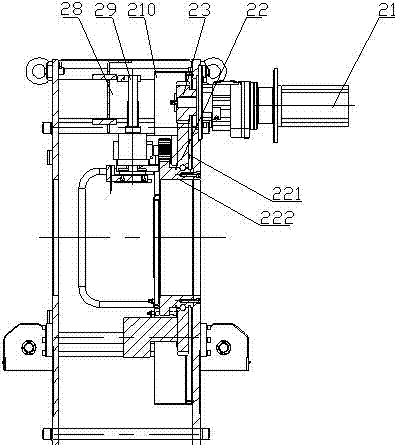

[0030] Such as Figure 3-5 As shown, the rotary mechanism 2 includes a cutting base plate with a cutting through hole, and a driving motor 21, a turntable bearing 22, a driving gear 23, an inner pinion 24, a feed screw 25, a cutting blade 26 and a driving motor installed on the cutting base plate. Lifting cutter 27, proximity switch fixed plate 28, spacer cover 29 and dust cover 210.

[0031] The rotating shaft of drive motor 21 is connected with driving gear 23, and turntable bearing 22 includes outer ring gear 221 and inner ring gear 222 that have t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com