Compound feed for piglets and preparation method thereof

A compound feed and trough compounding technology, applied in animal feed, animal feed, application, etc., can solve the problems of not being able to meet the nutritional needs of suckling pigs, not being able to exert the production performance of sucking pigs, and not being suitable for the nutritional needs of suckling pigs, and achieve the benefit of Digestion and absorption, increased weaning weight, and improved disease resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

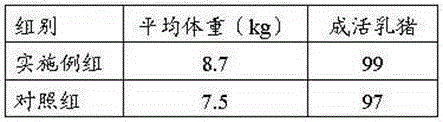

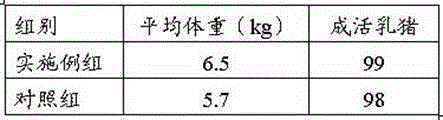

[0021] Aiming at the problem that the traditional suckling pig feed is not suitable for the nutritional needs of suckling pigs in the early stage of nursery, the present invention provides a suckling pig trainer compound feed that meets the nutritional needs of suckling pigs in the early stage of nursery. The various raw materials in the compound feed and their weight percentages are : Corn 15.72%, flour 25%, broken rice 11%, soybean meal 18%, soybean oil 2%, whey powder 8%, glucose 8%, plasma protein powder 4%, fish meal 3%, intestinal membrane protein 3%, phosphoric acid Calcium dihydrogen 0.6%, salt 0.1%, sodium butyrate 0.1%, acidifier 0.3%, emulsifier 0.1%, microecology 0.03%, choline chloride 0.05%, premix 1%.

[0022] Among them, the active ingredients of the acidifier are benzoic acid, fumaric acid and calcium DL-hydroxymethionine; the active ingredients of the emulsifier are soybean lecithin extract, that is, lysolecithin; the active ingredients of the microecology are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com