Running-in testing method of loading running-in device for ball screw pair

A ball screw pair and testing method technology, applied in the direction of machine gear/transmission mechanism testing, etc., can solve the problem that the performance of the ball screw pair cannot be accurately reflected, the force environment of the ball screw pair cannot be simulated, and the hydraulic cylinder structure Complicated and other problems, to achieve the effect of small occupied space, improved factory performance, and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

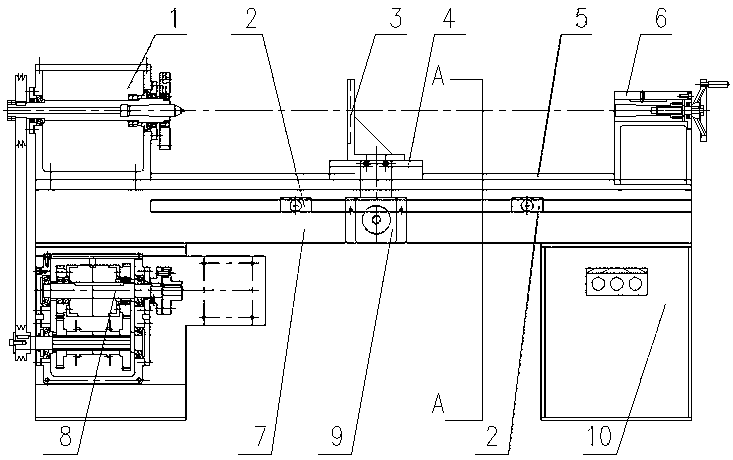

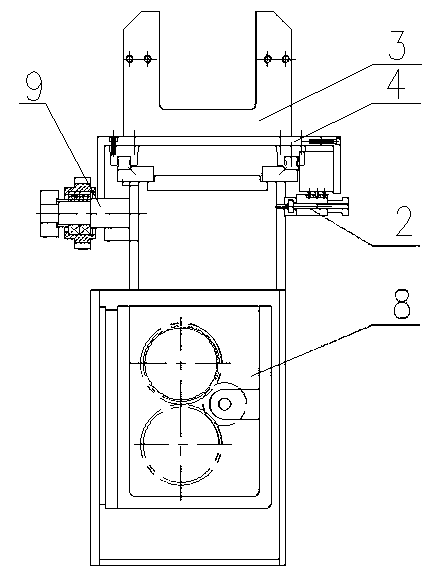

[0045] In the loading and running-in device of the ball screw pair in this embodiment, the headstock 1 is fixed on one end of the bed 7 by bolts, the tailstock 6 is slid on the slide rail of the bed 7, and the headstock 1 and the tailstock 6 are located on the bed respectively. The two ends of the body 7, the tailstock 6 can move on the slide rail of the bed 7, the tops of the headstock 1 and the tailstock 6 are located on the same horizontal line, and the ball screw pair is clamped on the headstock and the headstock through the central holes at both ends. The top ends of the tailstock are strengthened and fixed by the chuck on the headstock 1, the carriage 4 is sleeved on the guide rail 5, and can slide in the axial direction of the guide rail 5, and the positioning plate 3 is fixed on the carriage 4 by screws , the positioning plate 3 is located above the carriage 4, the positioning plate 3 is provided with a U-shaped groove, the two sides of the U-shaped groove are provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com