Multi-blade multi-angle rock breaking device for rock ripper

A technology for roadheaders and rocks, which is applied in the field of multi-knife and multi-angle rock-breaking test devices for simulating rock roadheaders, can solve the problems of not being able to detect the force state of the cutters under annular confining pressure, and achieve improved design levels, accurate measurement values, The effect of high rock breaking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

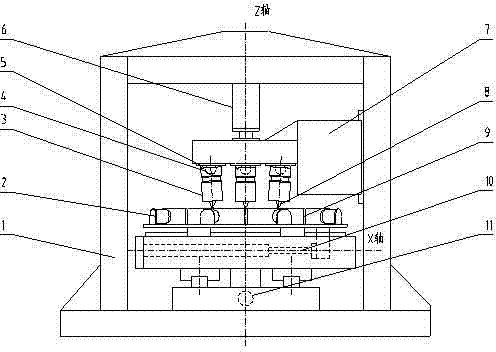

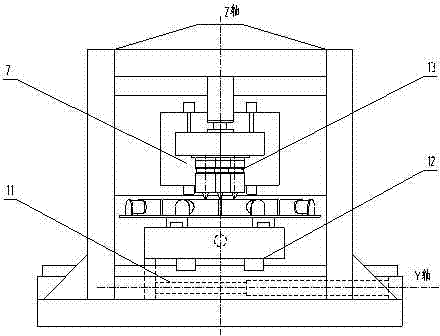

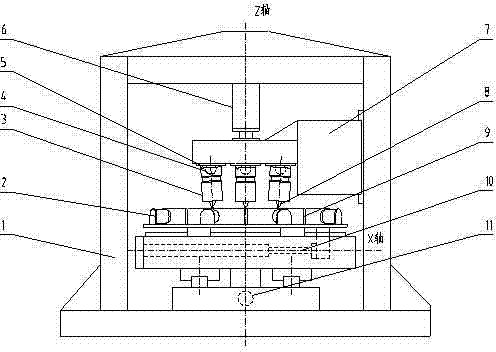

[0010] Referring to the accompanying drawings, a multi-knife and multi-angle rock breaking device for a rock boring machine is composed of a self-reflexive force frame body 1, an annular confining pressure loading table 2, a tool seat 3, a ball hinge seat 4, a tool angle adjustment snap ring 5, Z-direction servo actuator 6, rail guiding mechanism 7, roadheader cutter 8, rock specimen 9, X-direction servo actuator 10, Y-direction built-in servo actuator 11, horizontal double-layer linear guide rail 12, three-way pressure The sensor 13 is composed of the rock test piece 9 lateral movement direction is set as the X axis, the rock test piece 9 advancing direction is set as the Y axis, and the direction perpendicular to the broken surface of the rock test piece 9 is set as the Z axis. The X-direction servo actuator 10 is installed between the horizontal double-layer linear guide rail 12 and the annular confining pressure loading table 2, and the Y-direction built-in servo actuator 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com