Three-edged sleeve type detection apparatus for tension force of steel wire rope and method thereof

A tension detection and steel wire rope technology, which is applied in tension measurement and other directions, can solve the problems of damaging the integrity of the steel wire rope, affecting the mechanical properties, and low detection efficiency, and achieves the effects of fast detection speed, convenient operation, and high detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

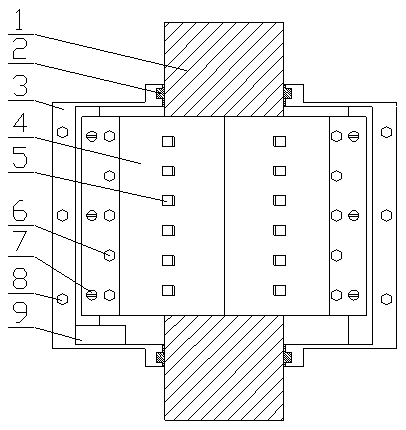

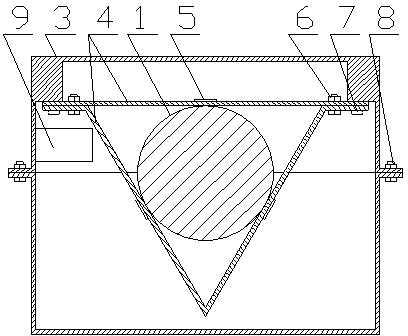

[0019] The triangular sleeve type steel wire rope tension detection device of the present invention comprises a triangular sleeve type tension sensing plate 4 buckled and pressed on the steel wire rope 1, and the material of the triangular sleeve type tension sensing plate 4 is a material with good strength and toughness. Made of high-quality carbon steel with a carbon content of 0.5% to 0.8%. The triangular sleeve-type tension sensing plate 4 is composed of a V-shaped plate and an in-line plate fixed and fastened on the V-shaped plate through the inner fastening bolt 6. The cross-section of the triangular sleeve-type tension sensing plate 4 is an equilateral triangle. The diameter of the inscribed circle of the equilateral triangle is 90% to 95% of the diameter of the steel wire rope 1 . 6 to 10 resistance strain gauges 5 are arranged at intervals at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com