Coupler synchronous type double-horizontal shaft vibration stirring machine

A technology of vibrating stirring and twin-horizontal shafts, which is applied in the direction of mixer accessories, shaking/oscillating/vibrating mixers, mixers with rotating stirring devices, etc. Uniformity, delaying the working time of the whole machine and other problems, to achieve the effect of improving the low efficiency area of mixing, easy to guarantee the life of the bearing, and low performance requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

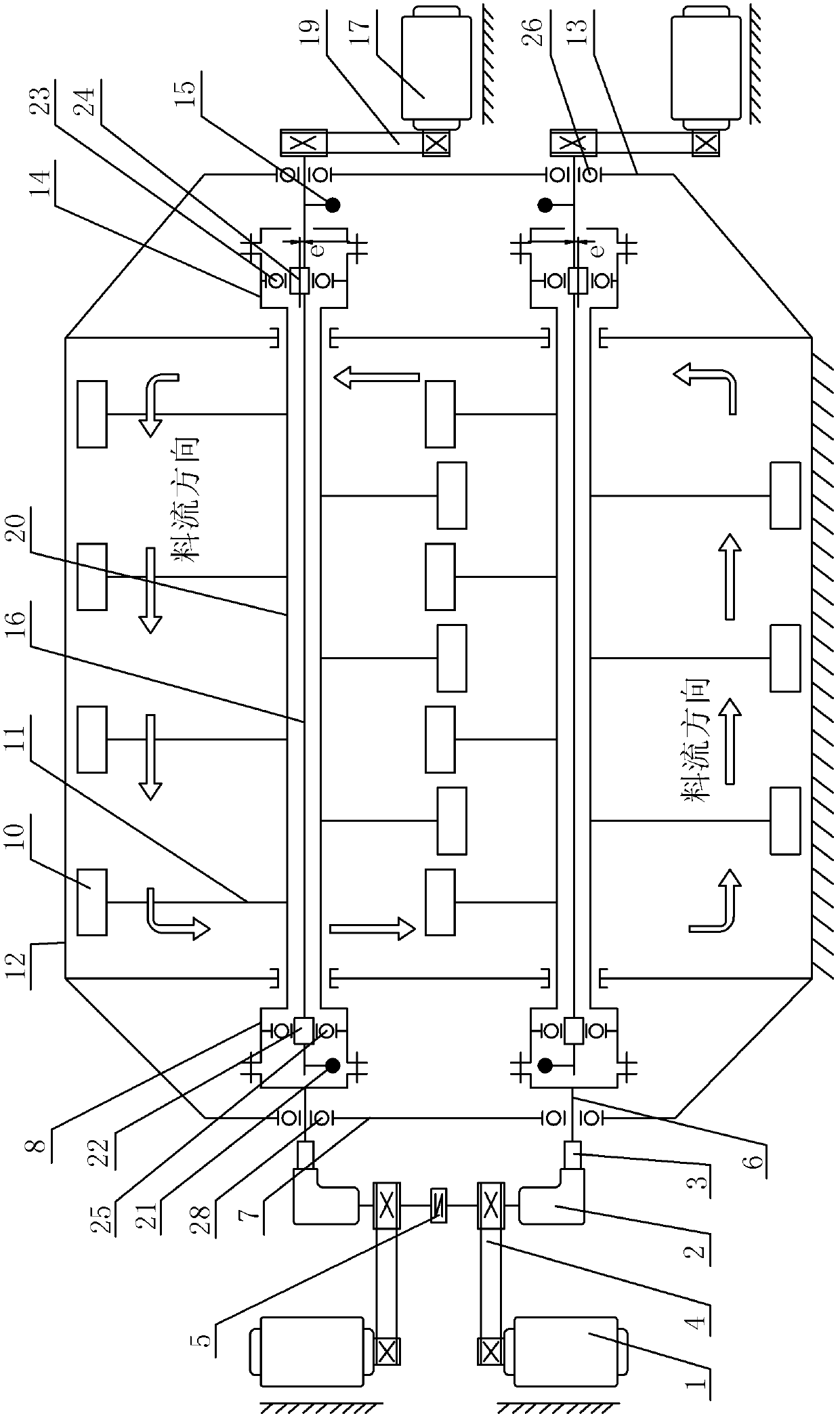

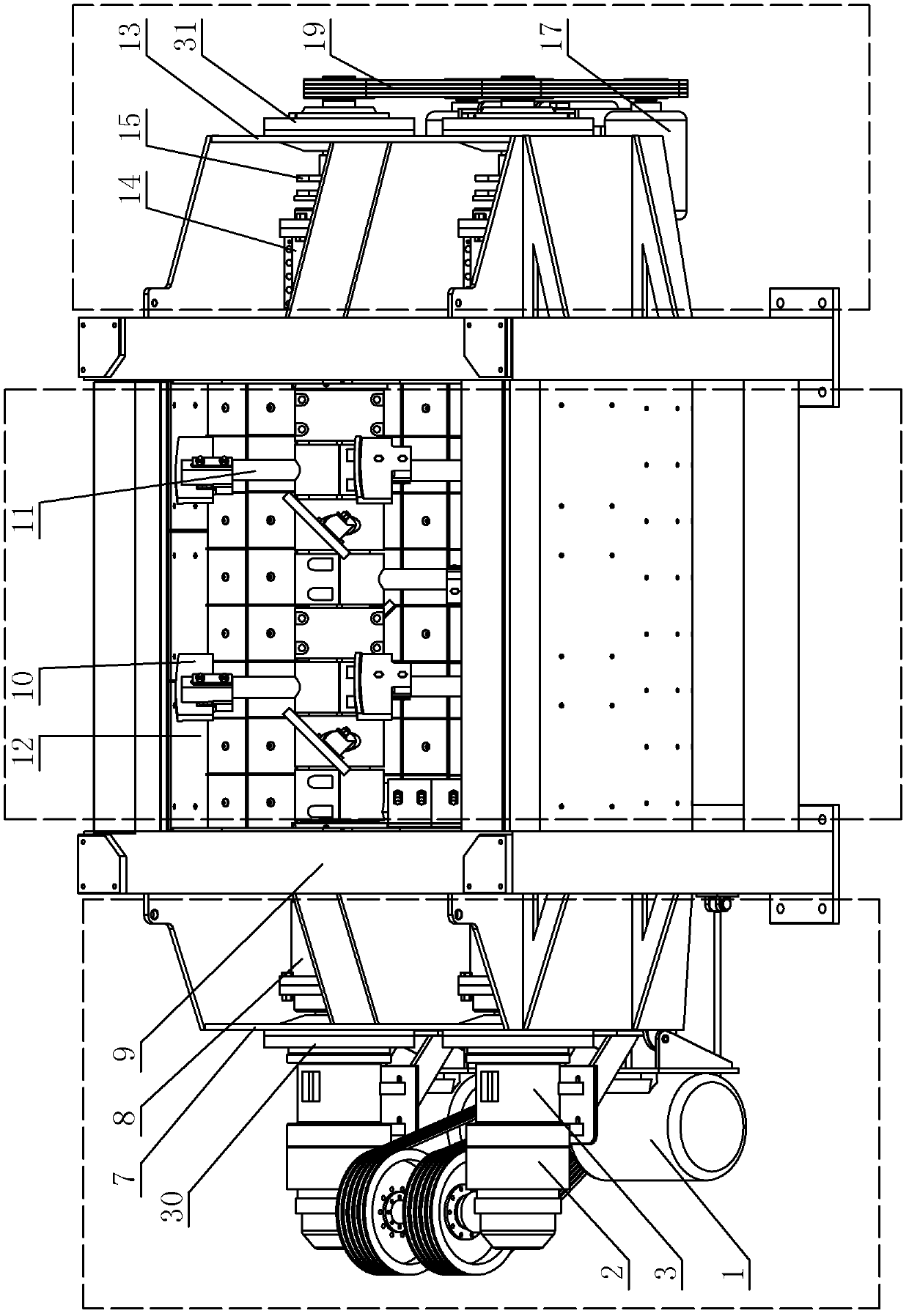

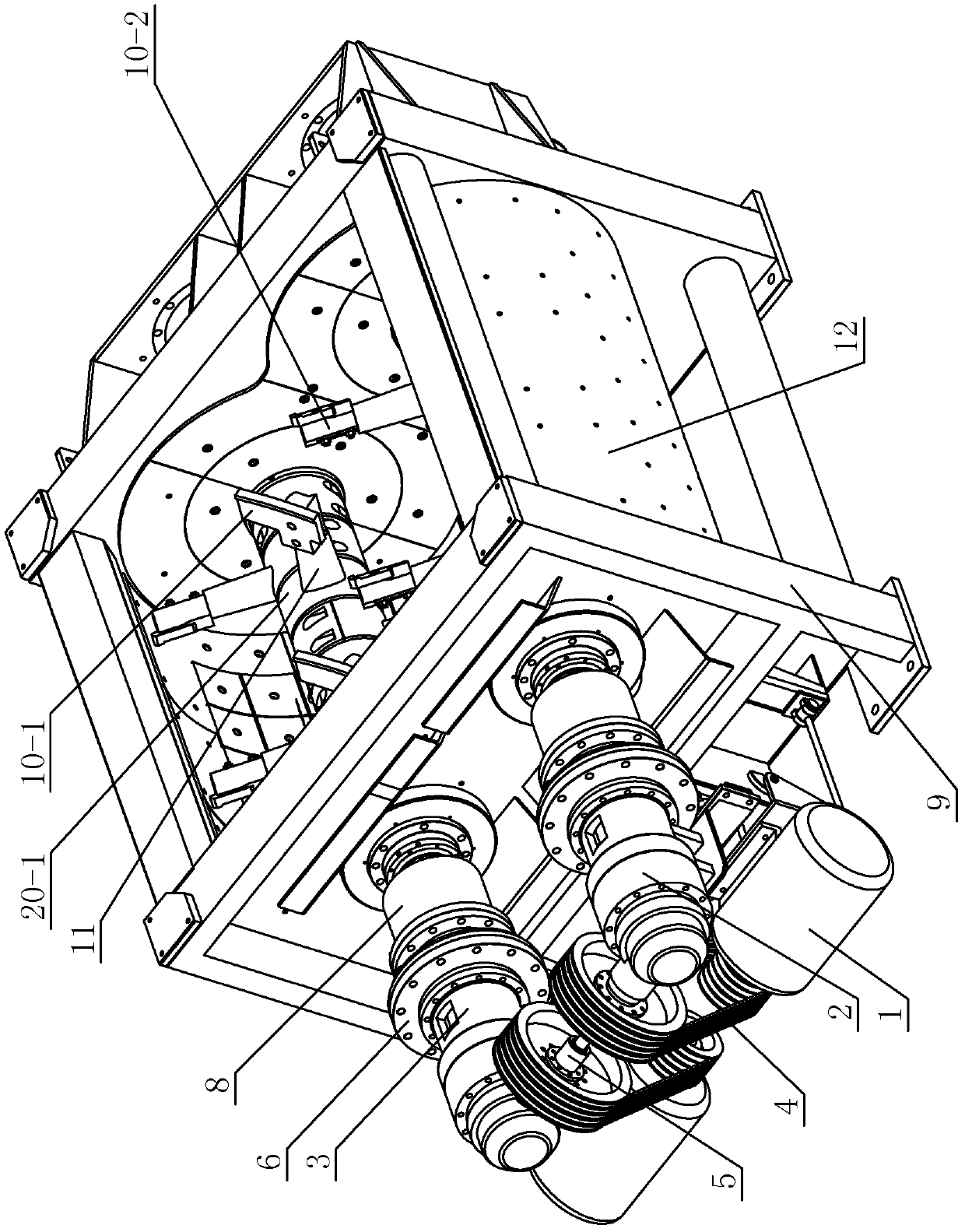

[0030] Such as Figure 1 to Figure 6 Shown, the present invention comprises frame 9 and the vibrating stirring device that is fixedly installed on frame 9, and the left end of described vibrating stirring device is provided with and is used for generating stirring driving force and the stirring driving force that produces is transmitted to described vibrating stirring device The stirring drive and transmission device, the right end of the vibration stirring device is provided with a vibration drive and transmission device for generating a vibration driving force and transmitting the generated vibration driving force to the vibration stirring device, and the stirring drive and transmission device pass through The outer plate 7 of the mixing drum at the stirring end is installed on the frame 9, and the vibration drive and transmission device are installed on the frame 9 through the outer plate 13 of the mixing drum at the vibrating end. Outer plate 13 is all fixedly connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com