Energy storage device of magnetic suspension flywheel

A flywheel energy storage and magnetic levitation technology, which is applied to electromechanical devices, magnetic attraction or thrust holding devices, and mechanical energy control, can solve the problems of complex structure of auxiliary systems, unsuitability for popularization, and increase of axial size, etc., to achieve Effects of improving reliability, improving energy conversion efficiency, and shortening axial dimension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

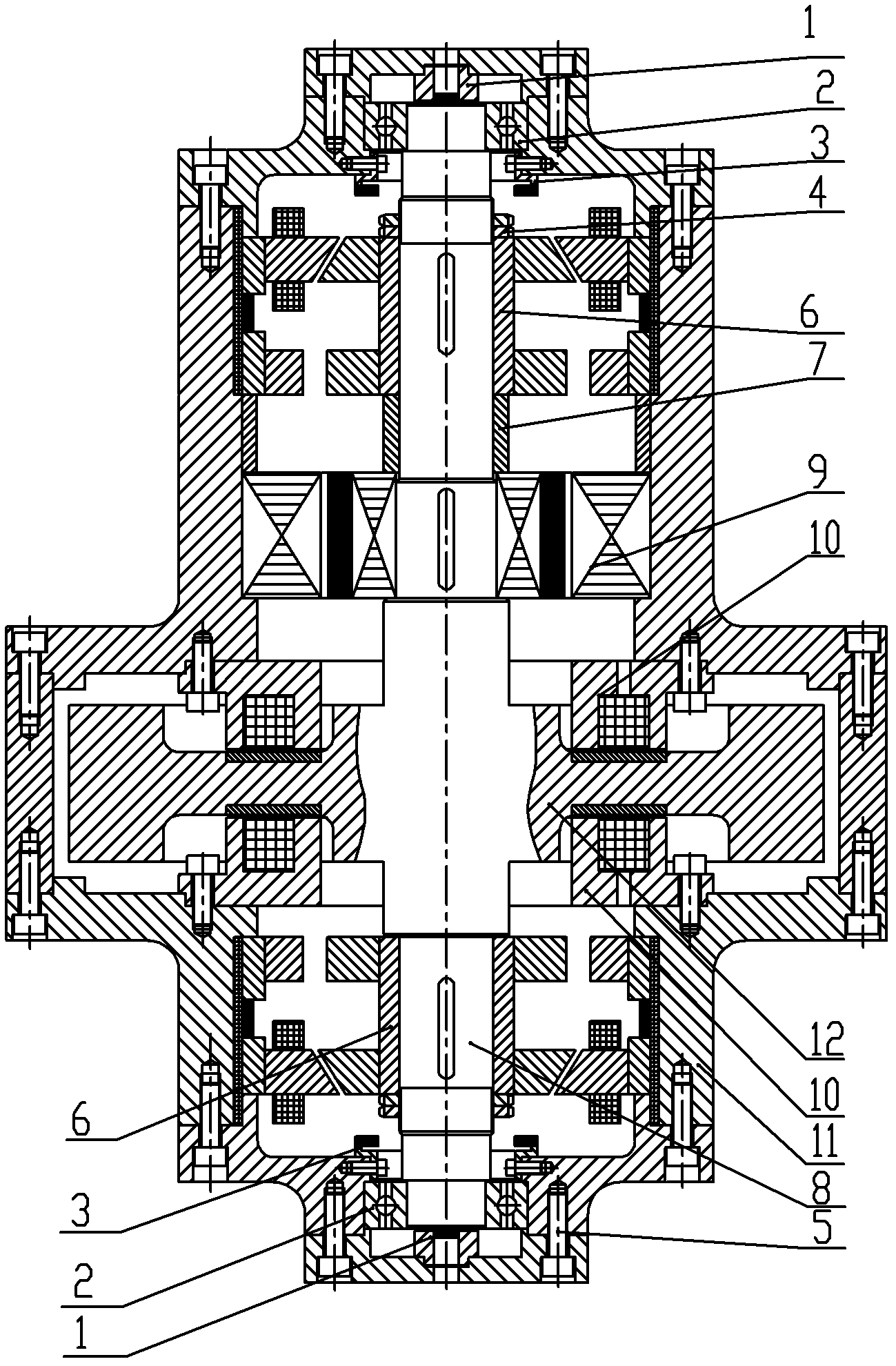

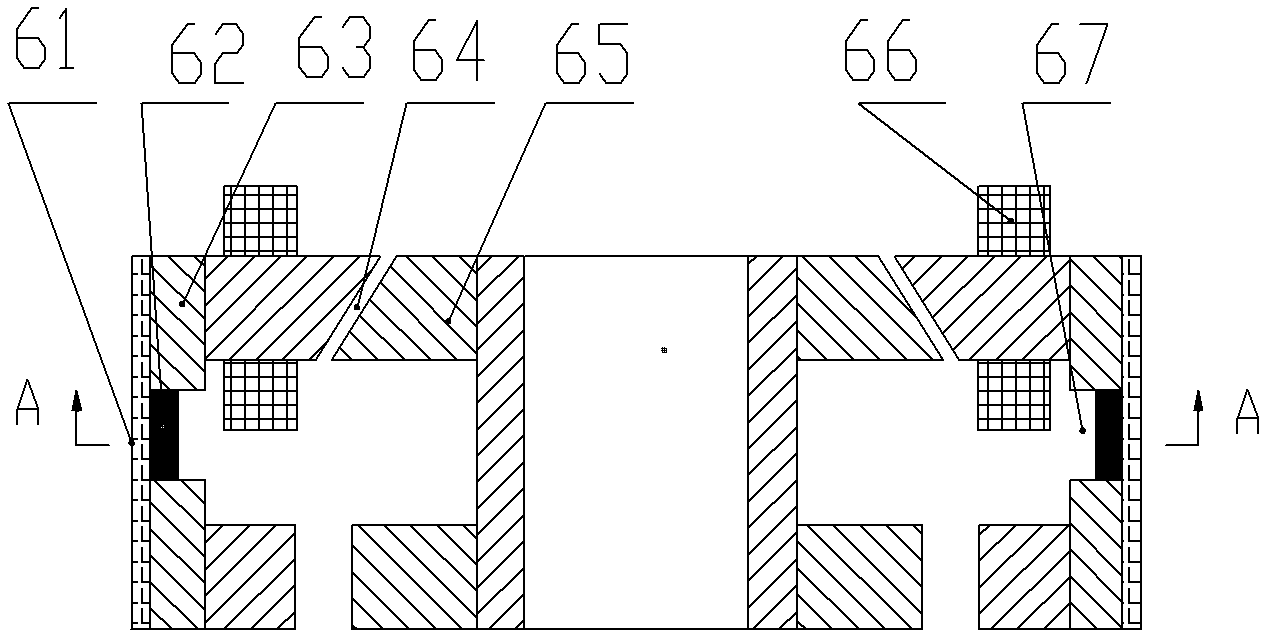

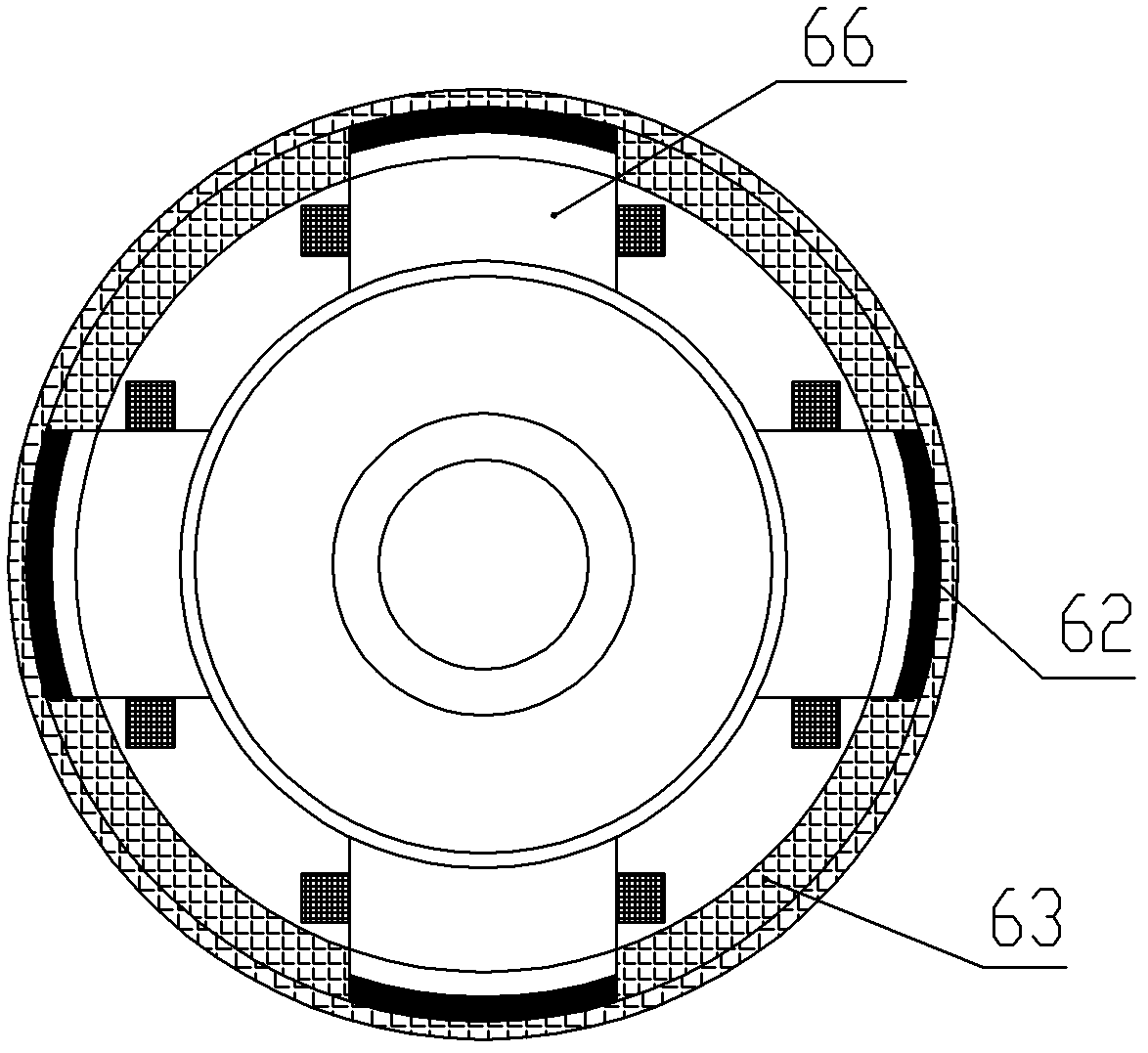

[0021] Such as figure 1 As shown, a magnetic levitation flywheel energy storage device includes an energy storage and conversion part, a magnetic levitation support part and an auxiliary part. The above-mentioned energy storage and conversion part includes flywheel 12, rotor and stator part of motor / generator 9; magnetic levitation support part includes radial hybrid conical magnetic bearing 6, axial magnetic bearing 10, axial sensor 1, radial sensor 3, Protect the bearing 2; the auxiliary part includes the housing 11, the installation shaft 8, the fastening nut 4 and the installation screw 5. Among them, the protective bearing 2, the radial hybrid conical magnetic bearing 6, the motor / generator 9, the axial magnetic bearing 10, the flywheel 12, the axial magnetic bearing 10, the radial hybrid conical magnetic bearing 6 and the protective bearing 2 on the installation shaft The axial direction is arranged sequentially from top to bottom, wherein the flywheel 12, the rotor par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com