Membrane electrode containing hydrophilic high polymer in anode catalytic layer and preparation method thereof

A technology of hydrophilic polymers and catalytic layers, which is applied to battery electrodes, circuits, electrical components, etc., can solve problems such as increased internal resistance, increased internal resistance of batteries, and cumbersome preparation processes, so as to avoid flooding and improve performance. Good, moisturizing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The first step is to take a 4cm×4cm Nafion212 proton exchange membrane, first place it in 5% hydrogen peroxide at 80°C for 1 hour, wash it with distilled water, and put it in 0.5moli -1 treated in a sulfuric acid solution at 80°C for 1 hour, and then washed with distilled water. Place the treated Nafion membrane on the fixed frame of the prepared membrane electrode and fix it, the size of the active area is 5cm 2 , to prevent the membrane from shrinking and deforming during the spraying of the catalyst slurry;

[0046] In the second step, 1 g of polyethylene glycol (PEG4000) was dissolved in 99 g of deionized water to obtain an aqueous solution of PEG with a concentration of 1% by mass;

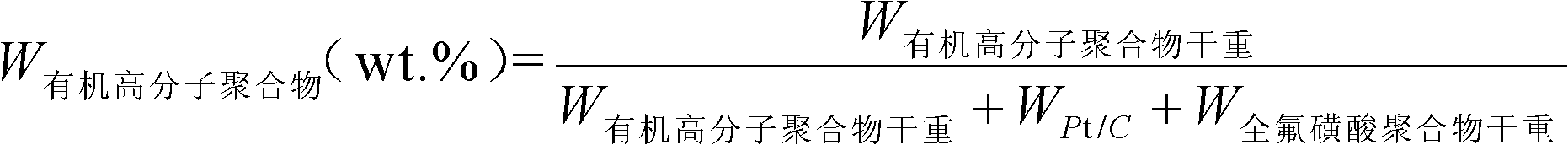

[0047] In the third step, 6.2 mg of Pt / C catalyst (Hispec 4100, Johnson Matthey) and 50 mg of perfluorosulfonic acid polymer solution (5wt% Nafion, DuPont), 8.8 mg of the PEG4000 solution prepared in the second step and 0.3 g of isopropanol were mixed and dispersed into a catalyst sl...

Embodiment 2

[0054] The first step is to take a 4cm×4cm Nafion 212 proton exchange membrane, first place it in 5% hydrogen peroxide at 80°C for 2 hours, wash it with distilled water, and put it in 0.5moli -1 treated in a sulfuric acid solution at 80°C for 2 hours, and then washed with distilled water. Place the treated Nafion membrane on the fixed frame of the prepared membrane electrode and fix it, the size of the active area is 5cm 2 , to prevent the membrane from shrinking and deforming during the spraying of the catalyst slurry;

[0055] The second step takes 0.1g polyvinyl alcohol (PVA) and dissolves it in 99.9g deionized water to obtain an aqueous solution of PVA whose mass percentage concentration is 1‰;

[0056] In the third step, 3.1 mg of Pt / C catalyst (Hispec 4100, Johnson Matthey) and 15 mg of perfluorosulfonic acid polymer solution (5wt% Nafion, DuPont), 44.2mg of the PVA solution prepared in the second step above and 0.2g of isopropanol, after mixing, disperse into a cataly...

Embodiment 3

[0060] Except in the third step, 3.1 mg of Pt / C catalyst (Hispec 4100, Johnson Matthey) with a Pt content of 40%, 15 mg of perfluorosulfonic acid polymer solution ( 5wt%Nafion, DuPont), 135.3mg of PVA aqueous solution and 0.2g isopropanol with a mass percentage concentration of 1‰, the loading of Pt in the anode catalyst layer is 0.1mg.cm -1, The added amount of PVA is 3wt.%.

[0061] During the determination of water content, except that 3.1 mg of Pt / C catalyst (Hispec 4100, Johnson Matthey) with a Pt content of 40%, 25 mg of perfluorosulfonic acid polymer solution were weighed in a mass ratio of 10:4:0.4:500, (5wt%Nafion, DuPont), the mass percent concentration of 135.3mg is except that the PVA solution of 1‰ and 0.2g isopropanol, other steps are identical with example 1, and water content determination method, battery activation mode and battery performance test method are the same as Example 1 is exactly the same.

[0062] The water content of the anode catalytic layer i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com