Detection method of scanning electron microscope

A technology of electron microscope and detection method, which is applied in the detection field of scanning electron microscope, can solve the problems such as difficult to meet the requirements of precision, affect the production capacity of the machine, and difficult to meet the requirements of detection speed, so as to achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

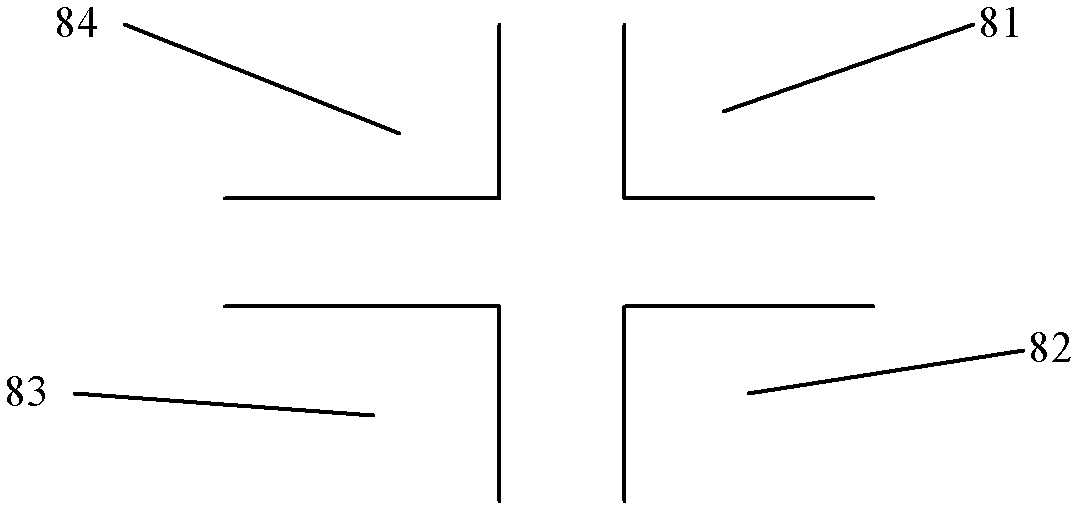

[0041] Please refer to figure 2 and also refer to Figure 7 . figure 2 is a schematic diagram of the definition of the chip corner. exist figure 2 In the figure, a part of four chips such as chip one 81 to chip four 84 and a "cross"-shaped space formed between these four chips are shown. In this embodiment, the geometric center (intersection) of the "cross"-shaped void part is defined as the "chip corner" described in the present invention. In a wafer, a chip corner can be formed between any four adjacent chips. Since the size of a single chip is often very small relative to the size of the wafer, in order to select the convenience and accuracy of the starting position, it is first necessary to select a certain chip corner as the starting position of defect detection.

[0042] However, it should be noted that the "chip corner" may also be selected as a certain corner of a single chip, which is not specifically limited in the present invention.

[0043] Please refer to...

Embodiment 2

[0051] The main parts of this embodiment are the same as those of Embodiment 1, and only the parts different from Embodiment 1 will be described below. After obtaining the chip-level deviation value, use the deviation value and the above-mentioned wafer-level deviation value to correct the coordinates obtained by the defect scanning machine for all defects on chip C4, and perform point-by-point scanning and photographing. Select another chip C5 afterwards, obtain the deviation value (Z5, W5) of the chip level of chip C5 again with the method described in embodiment 1, then obtain the defect scanning machine of all defects on the chip C5 according to the above-mentioned method The obtained coordinates are corrected, scanned point by point and photographed. By analogy, a corresponding chip-level deviation value (Zn, Wn) is obtained for each chip Cn, and this deviation value is used together with the wafer-level deviation value to correct defects in the chip, and the above method...

Embodiment 3

[0053] Different from Embodiment 2, in order to improve the detection efficiency, after obtaining the deviation value of the wafer level and the deviation value of the chip level of a selected chip, all defects on the wafer to be tested can be obtained in the defect scanning machine. The coordinates are corrected, and the image is captured.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com