Jet type heat pump adopting multi-effect cascade ejecting mode and large pressure ratio vacuum pump

A jet heat pump and vacuum pump technology, applied in jet pumps, heat pumps, non-displacement pumps, etc., can solve the problems of low ejection ratio, high energy consumption, increased fluid pressure, etc. The effect of expanding the field of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

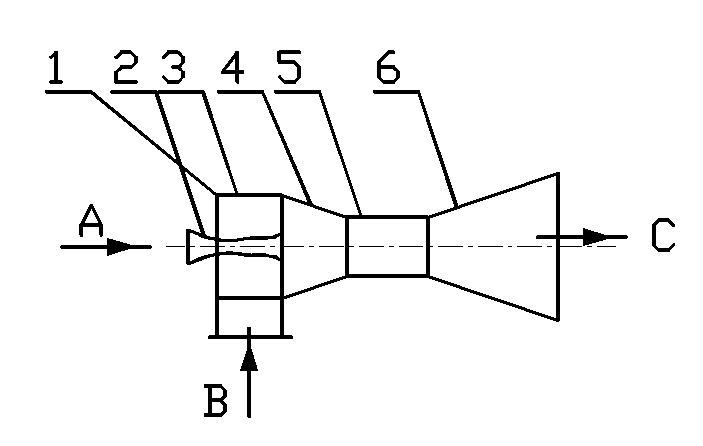

Embodiment 1

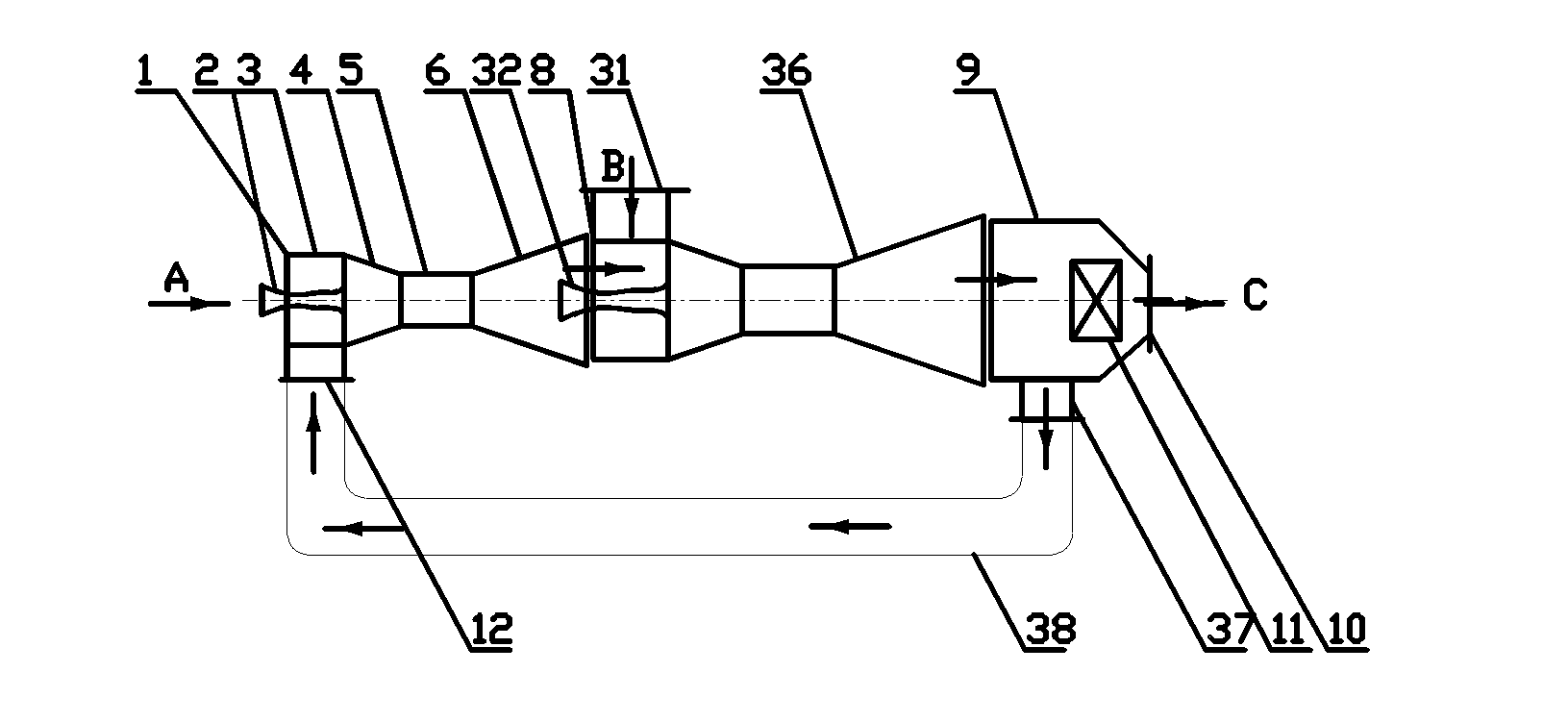

[0023] Embodiment 1: A jet heat pump and a vacuum pump with a large pressure ratio using a multi-stage cascade injection method with a two-stage structure, such as figure 2 As shown, this embodiment adopts a cascade structure in which two stages are connected in series and parallel and drives the fluid to perform work in stages, including the first-stage injector 1, the last-stage injector 8, and the last-stage flow distributor 9 connected sequentially in a cascaded manner; Both the first-stage injector 1 and the last-stage injector 8 are composed of an inlet section 3 with nozzles, a mixing section 4, a throat 5 and a diffuser section 6 connected in sequence, and the last-stage flow distributor 9 has a final-stage mixing guide. The outlet 37 and the mixed fluid outlet 10, the first-stage injection port 12 of the first-stage injector 1 is connected with the last-stage mixing outlet 37 of the last-stage diffuser section 36 of the last-stage injector 8 through the last-stage inj...

Embodiment 2

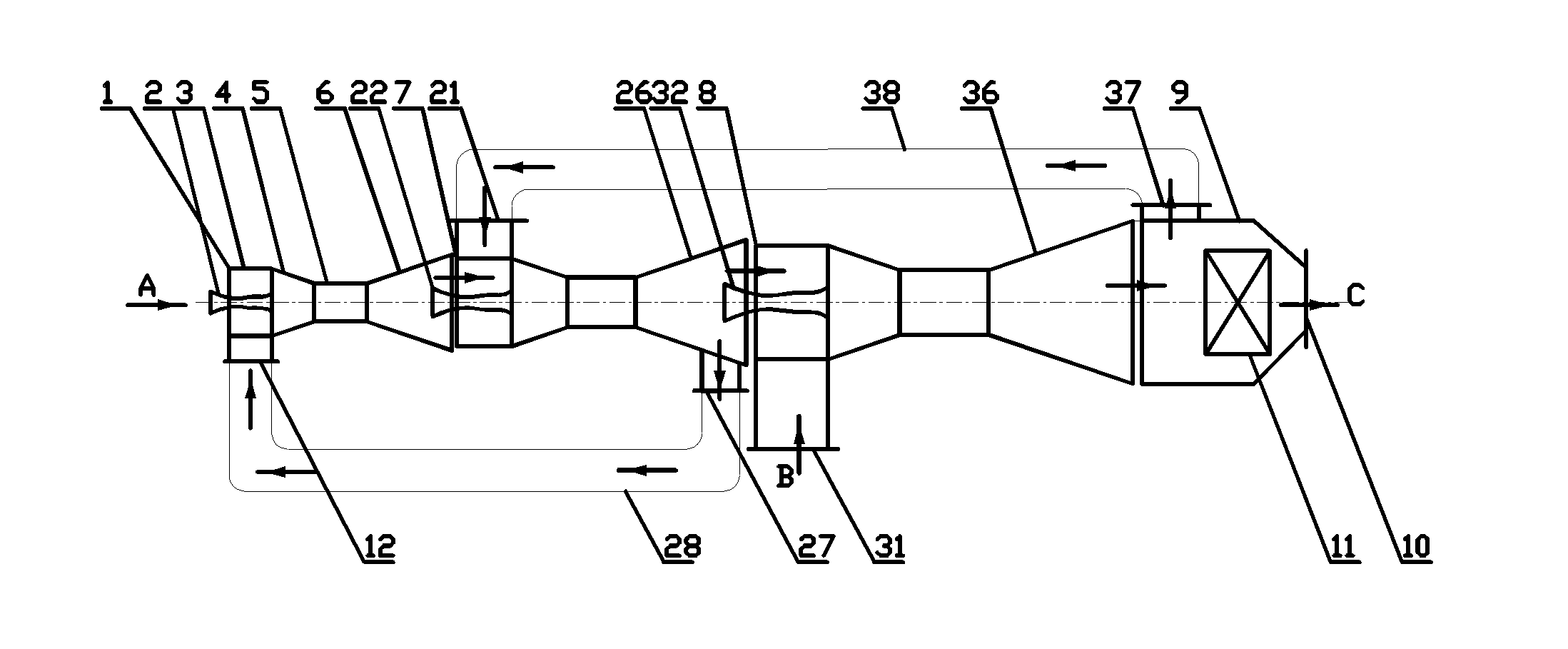

[0026] Embodiment 2: A jet heat pump and a vacuum pump with a large pressure ratio using a multi-stage cascade injection method with a three-stage structure, such as image 3 As shown, the difference between Embodiment 2 and the above-mentioned Embodiment 1 is that an intermediate-stage injector structure is added, and the fluid inlet and outlet processes of each stage are adjusted accordingly. The specific adjustments are as follows: Cascade first-stage injector 1 The first-stage diffuser section 6 of the first stage is first connected with the inlet section of the cascade-type intermediate-stage injector 7, and then connected with the inlet section of the cascade-type final-stage injector 8 after passing through the intermediate-stage diffuser section 26, and the cascade-type final-stage 8, the final stage mixing outlet 37 of the final stage flow distributor 9 is connected with the intermediate stage injection port 21 of the cascade intermediate stage 7 through the final inje...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com