Internal steel tube confined reinforced concrete hollow pier

A technology of reinforced concrete and inner steel pipes, which is applied in the field of bridge pier structures, can solve problems such as changes in the mechanical properties of concrete outside, difficulty in erecting and dismantling internal formwork, and internal support of difficult external concrete, so as to eliminate erection and demolition procedures and avoid adverse effects , the effect of improving bearing capacity and ductility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

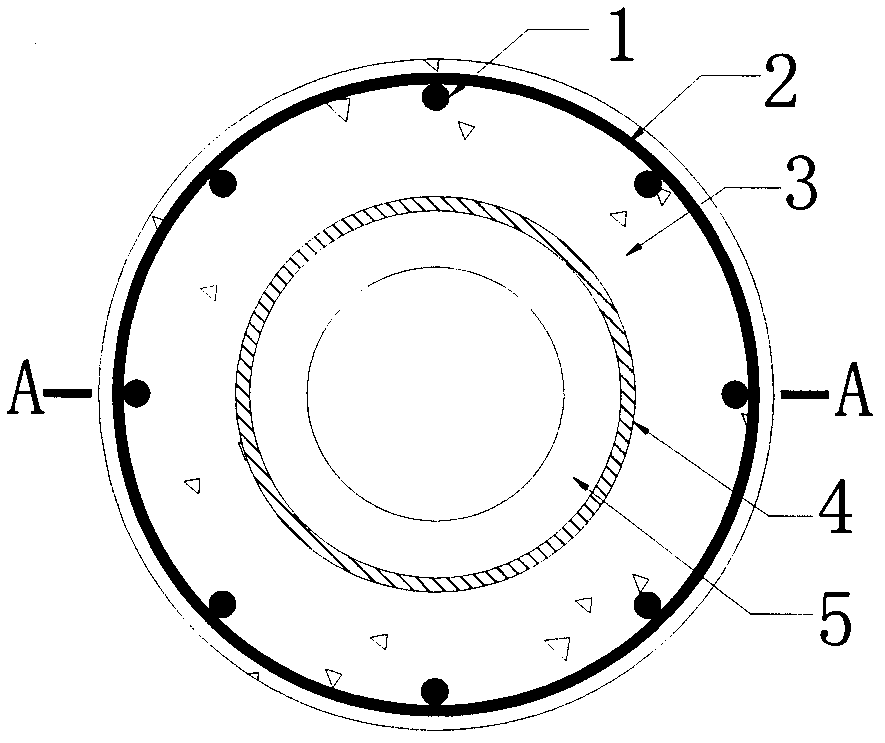

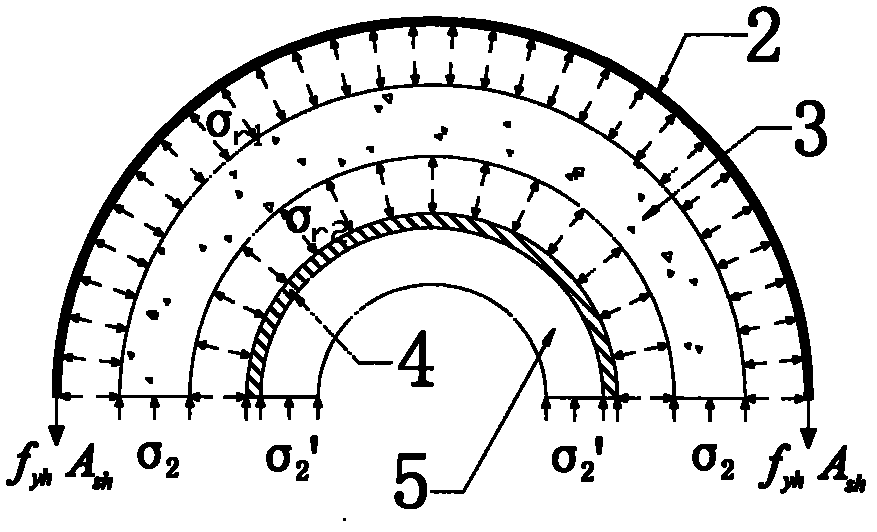

[0035] Figure 4 ~ Figure 11 The cross section of the pier and the inner steel pipe are one of circular cross section, rectangular cross section, oval cross section, round end cross section or hexagonal cross section; the pier cross section is rectangular cross section, the inner steel pipe is circular cross section; the pier cross section is Schematic diagram of cross-sectional structure of reinforced concrete hollow piers with inner steel pipes constrained by inner steel pipes with circular cross-section and inner steel pipe as rectangular cross-section; pier with hexagonal cross-section and inner steel pipe as circular cross-section.

[0036] In the specific implementation, the inner steel pipe 4 and the diaphragm 5 are processed first. The middle part of the diaphragm 5 is hollow and ring-shaped, and the cross-sectional shape is the same as that of the inner steel pipe 4. The thickness of the steel plate of the partition 5 should not be less than 5mm, and its width should ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com