Preparation method of temperature-sensitive cellulose quaternary ammonium salt/beta-sodium glycerophosphate hydrogel

A technology of sodium glycerophosphate and cellulose is applied in the field of materials and tissue engineering, and achieves the effects of simple method, good biocompatibility and low cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

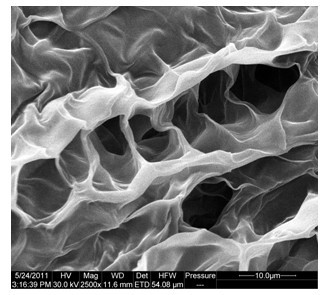

Image

Examples

Embodiment 1

[0027] Configured with 8wt% LiOH·H 2 O, 550 mL of an aqueous solution of 15 wt % urea, pre-cooled to -10 ° C, added 11 grams of cellulose at room temperature, and mechanically stirred for 3 to 5 minutes to obtain a cellulose solution (2 wt %). 111.0 g of 3-chloro-2-hydroxypropyltrimethylammonium chloride aqueous solution (69 wt %) was added dropwise to the cellulose solution, stirred for 24 hours, and then HCl was added to neutralize the reaction solution. The reaction solution was dialyzed with distilled water for 7 days and freeze-dried to obtain a white fibrous cellulose quaternary ammonium salt sample (substitution degree DS=0.34, nitrogen content 2.23%).

[0028] Dissolve 250 mg of cellulose quaternary ammonium salt (DS=0.34) in 8.5 mL of 0.1 mol / L acetic acid aqueous solution and mix evenly to form a 2.9 wt % solution. Dissolve 650 mg of β-sodium glycerophosphate in 1.5 mL of deionized water to form a 43.3 wt % solution. At 15°C, add 1.5mL of β-sodium glycerophosphate ...

Embodiment 2

[0030] According to the method of Example 1, a white fibrous cellulose quaternary ammonium salt sample with a degree of substitution DS=0.34 was prepared.

[0031] Dissolve 250 mg of cellulose quaternary ammonium salt (DS=0.34) in 8.5 mL of 0.1 mol / L acetic acid aqueous solution and mix evenly to form a 2.9 wt % solution. Dissolve 760 mg of sodium β-glycerophosphate in 1.5 mL of deionized water to form a 50.7 wt % solution. In an ice-water bath at 4°C, add 1.5mL of β-sodium glycerophosphate solution dropwise to 8.5mL of cellulose quaternary ammonium salt solution, and stir thoroughly to obtain a cellulose quaternary ammonium salt / β-sodium glycerophosphate solution, and the final mixed solution The concentration of β-glycerophosphate sodium in the medium is 7.6wt%, the concentration of cellulose quaternary ammonium salt is 2.5wt%, and when it is placed in a water bath at 37°C, the solution will quickly solidify within 30 seconds to form a hydrogel.

Embodiment 3

[0033] According to the method of Example 1, a white fibrous cellulose quaternary ammonium salt sample with a degree of substitution DS=0.34 was prepared.

[0034] Dissolve 400 mg of cellulose quaternary ammonium salt (DS=0.34) in 8.5 mL of 0.1 mol / L acetic acid aqueous solution and mix well to form a 4.7 wt % solution. Dissolve 300mg of β-sodium glycerophosphate in 1.5mL of deionized water to prepare a 20wt% solution. In an ice-water bath at 4°C, add 1.5mL of β-sodium glycerophosphate solution dropwise to 8.5mL of cellulose quaternary ammonium salt solution, and stir thoroughly to obtain a cellulose quaternary ammonium salt / β-sodium glycerophosphate solution, and the final mixed solution The concentration of β-glycerophosphate sodium in the medium is 3wt%, and the concentration of cellulose quaternary ammonium salt is 4wt%. After standing still in a water bath at 37°C, the solution will quickly solidify within 30 seconds to form a hydrogel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com