Method for pretreating and strengthening sludge dehydration by using acetylene sludge

A technology of sludge dehydration and carbide slag, which is applied in the direction of dehydration/drying/concentrated sludge treatment, etc., can solve the problems of high energy consumption, threats to the surrounding environment of transportation routes, and increase the difficulty of transportation, etc., and achieve significant technical and economic effects. Facilitate disposal and utilization, reduce dehydration energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

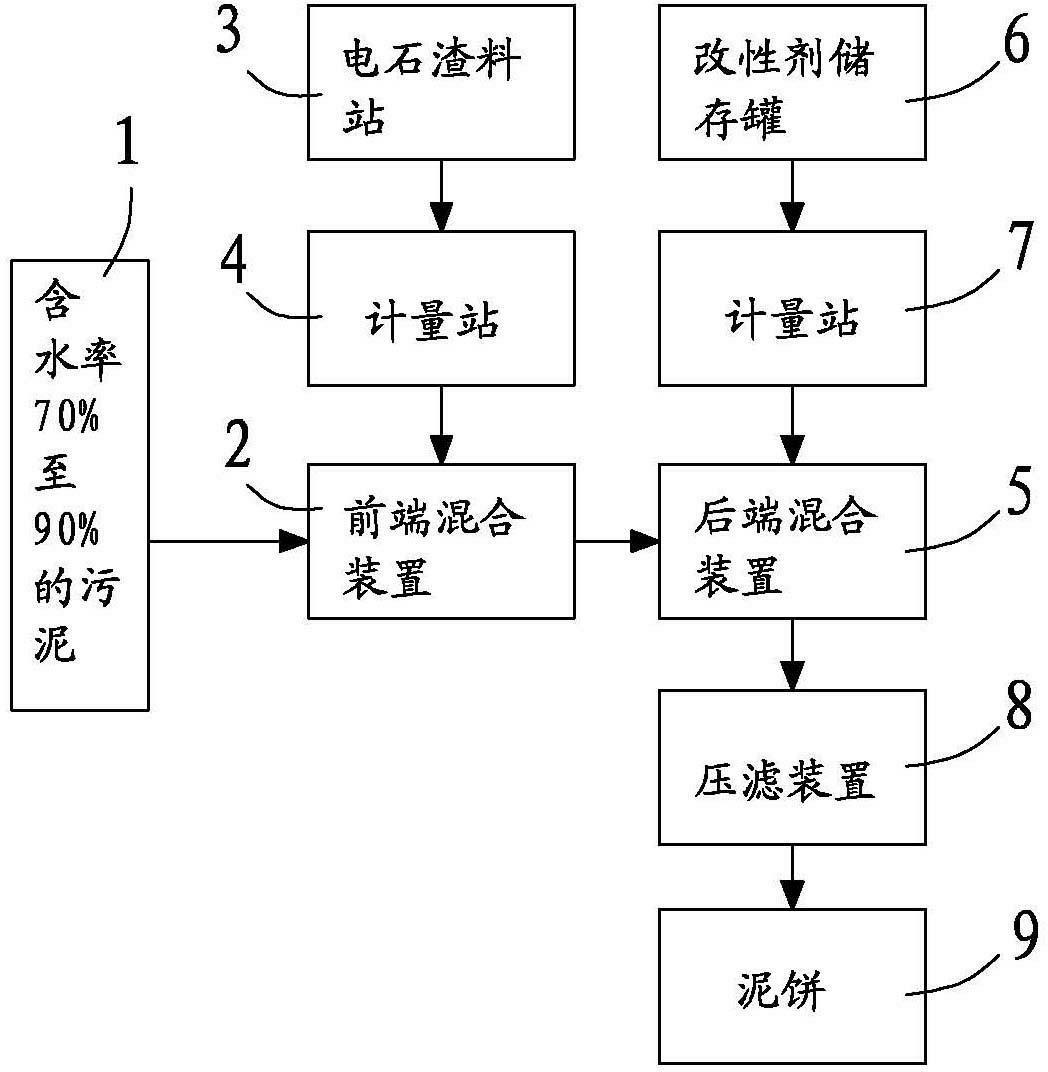

[0021] An embodiment of a method for utilizing carbide slag pretreatment to strengthen sludge dehydration, see figure 1 , the method comprises adding a modifying agent to the sludge and extruding the sludge, wherein the sludge is firstly processed by adding carbide slag before adding the modifying agent, and the steps of the sludge dehydration method are:

[0022] a. Mix sludge with a moisture content greater than 70% into calcium carbide slag and mix evenly for more than 10 minutes to obtain mixed sludge. The amount of calcium carbide slag is 1% to 50% of the total amount of sludge;

[0023] b. Continue to add 0.5% to 2% modifier of the total amount of sludge for stirring, and the stirring time is longer than 1 minute to obtain sludge with modifier added;

[0024] c. The sludge added with modifier is sent to a plate and frame filter press for extrusion to obtain a dehydrated cake.

[0025] Calcium carbide slag is the waste residue with calcium hydroxide as the main component...

Embodiment 2

[0029] Referring to Example 1, this example is a further preferred example of the content of Example 1. Therefore, the method is further as follows: mixing sludge with a moisture content of 80% and a particle size of 80 mesh to 80 mesh with a moisture content of not more than 30% 100-mesh carbide slag, the mixed calcium carbide slag is 5% of the total volume of the sludge, stirred for 15 minutes, then added a modifier of 0.5% to 2% of the total volume of the sludge, continued to stir for 2 minutes, and sent to the plate Frame filter press to obtain a mud cake with a moisture content of 62% to 64%.

Embodiment 3

[0031] Referring to Example 1, this example is a further preferred example of the content of Example 1. Therefore, the method is further as follows: mixing sludge with a moisture content of 80% and a particle size of 80 mesh to 80 mesh with a moisture content of not more than 30% 100-mesh carbide slag, in which the mixed calcium carbide slag accounts for 8% of the total volume of the sludge, stirred for 15 minutes, then added a modifier that is 0.5% to 2% of the total volume of the sludge, continued to stir for 2 minutes, and sent into Plate and frame filter press to obtain mud cake with a moisture content of 54% to 56%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com