On-line detection and rejection device for cigarette packaging machine to reject cigarette

A technology of removing device and packaging machine, which is applied to packaging cigarettes, cigars and other directions, can solve the problems of large occupied space, low efficiency, complex structure, etc., and achieve the effects of reducing waste, convenient operation and improving effective operation rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

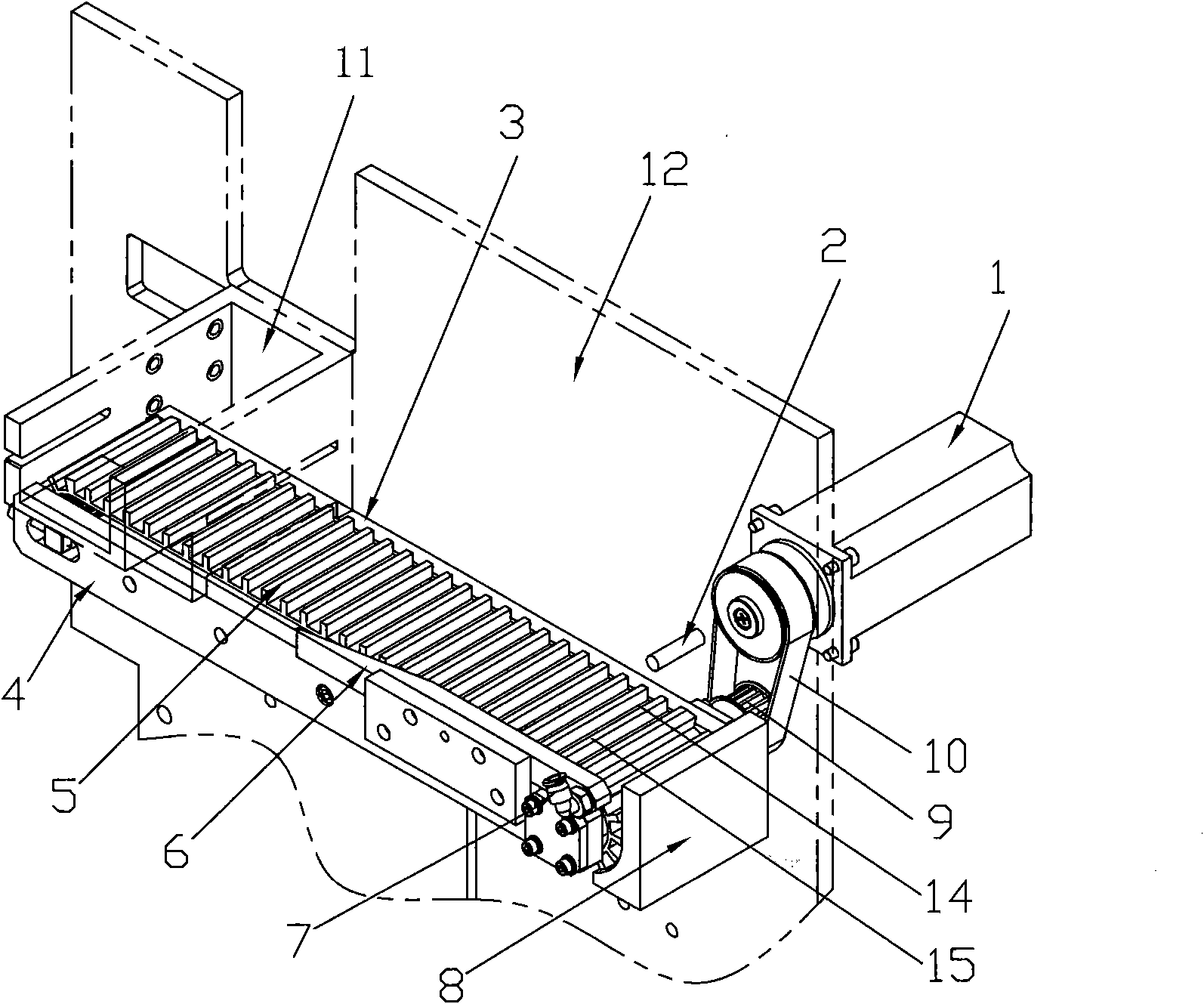

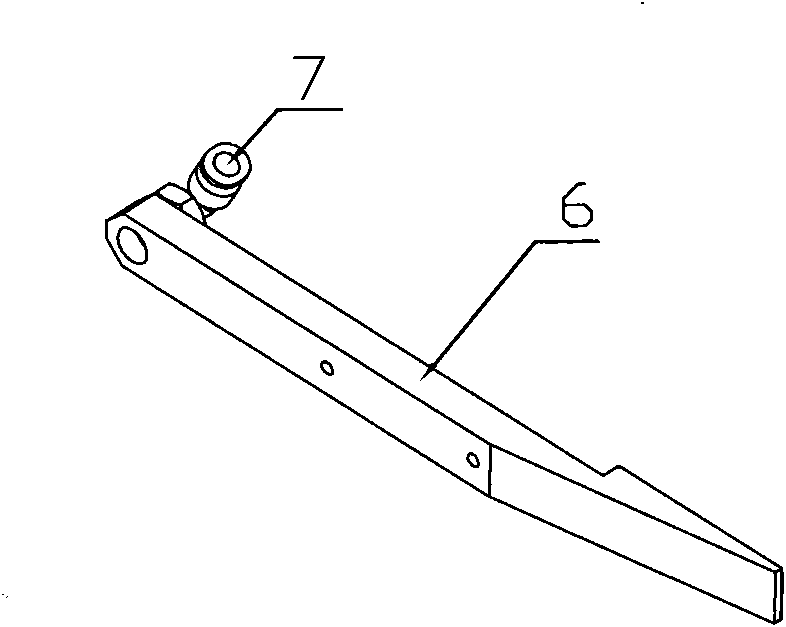

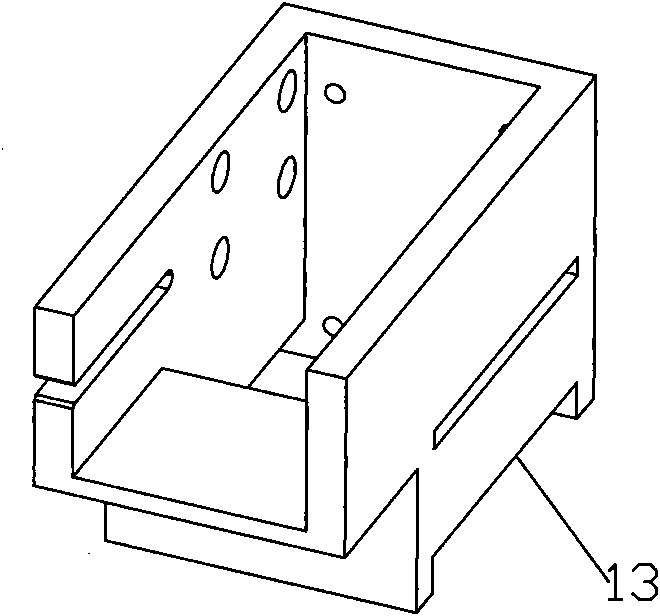

[0017] Embodiment 1: as figure 1 As shown, the present invention includes a detection belt 5, a servo motor 1, a baffle plate 8, a wedge block 6, the first and second side plates 3, 4 and an empty head detection sensor 2 placed on both sides of the detection belt 5, and the servo The output shaft of the motor 1 is connected to the driving shaft 9 of the detection belt 5 through a transmission belt 10, and is driven by the servo motor 1. One end of the detection belt 5 is located below the smoke outlet of the lower hopper 11, and the other end is provided with a baffle 8 to detect the movement of the belt 5. Wedge block 6 is installed on the second side plate 4, and the side of wedge block 6 with inclined plane is close to detection belt 5, and the end of wedge block 6 near baffle plate 8 is equipped with rejecting air nozzle 13, in the first The position corresponding to the wedge-shaped stopper 6 on the side plate 3 is equipped with a short-end detection sensor 2, and the sig...

Embodiment 2

[0024] Embodiment 2: the overall structure of this example is the same as that of embodiment 1, and the difference is that the distance between two adjacent shaped baffles 14 on the detection belt 5 described in this example is 8mm, and the height of the smoke groove 15 is 7.5mm. The width of the belt 5 is 12 mm less than the length of the cigarette, so that the width of the smoke slot 15 formed between the strip baffles 14 of the detection belt 5 is slightly larger than the diameter of the cigarette, and the height is slightly smaller than the diameter of the cigarette. Each smoke slot 15 can only accommodate one cigarette. , so that the cigarettes are arranged neatly. The distance between the bottom surface of the smoke groove 15 of the detection belt 5 and the top surface 13 of the side plate groove of the lower hopper 11 is greater than the diameter of the cigarette by 1mm, so that the cigarette outlet can only accommodate one cigarette to pass through, and the remaining ci...

Embodiment 3

[0025] Embodiment 3: the overall structure of this example is the same as that of embodiment 1, and the difference is that the distance between the two adjacent shaped baffle plates 14 on the detection belt 5 described in this example is 8.5mm, and the height of the smoke groove 15 is 7.2mm. The width of the detection belt 5 is 10mm less than the length of the cigarette. The distance between the bottom surface of the smoke groove 15 of the detection belt 5 and the top surface 13 of the side plate groove of the lower hopper 11 is greater than the diameter of the cigarette by 3mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com