Device for measuring normal vector at arbitrary point on free-form surface and measuring method thereof

A technology of normal vector and arbitrary point, which is applied in the measurement of positioning in boring machine/drilling machine, components of boring machine/drilling machine, drilling/drilling equipment, etc., can solve the problem of not being able to effectively solve the problem of real-time calculation of the normal vector of drilling and riveting points , Unable to realize the coordinate measurement of the data points of the skin panel, losing the premise of application, etc., to achieve the effect of simple structure, high reliability, and less measurement data points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

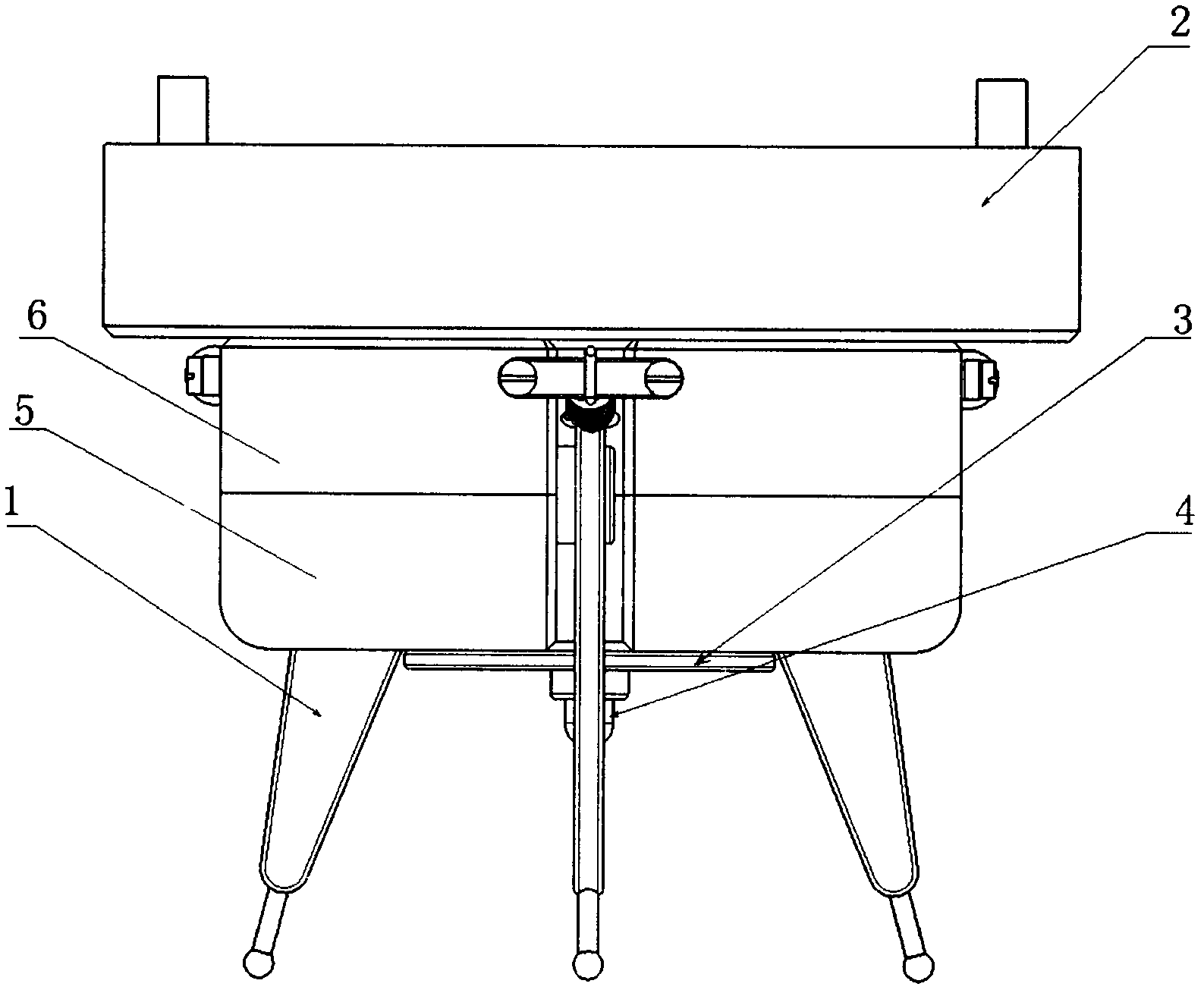

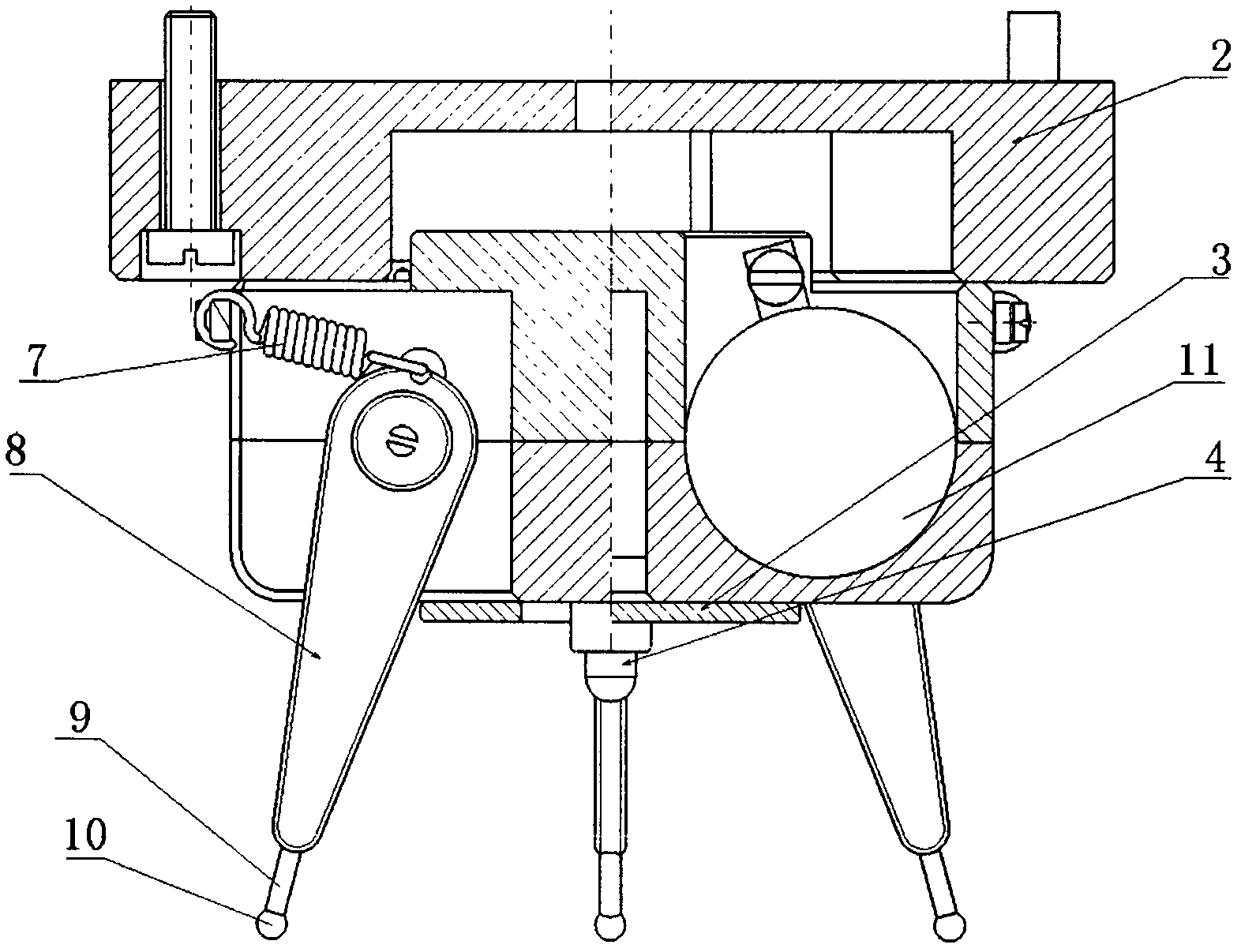

[0033] This embodiment is to measure the normal vector of the riveting point to be drilled on the aircraft skin. Since most of the modern aircraft skins are free and complex curved surfaces, in order to quickly and accurately measure the normal vector of the riveting point to be drilled, in this embodiment The measuring device proposed by the present invention is used for measurement.

[0034] Refer to attached figure 1 , the device includes a main body fixing assembly and four deflection angle measuring mechanisms 1 . The main body fixing assembly is composed of a connecting base 2 and a box body. The box body is divided into an upper box body 6 and a lower box body 5. The upper box body 6 and the lower box body 5 are fixedly connected by bolts, and one side of the connection base 2 is connected to the upper box body 6. The other side of the connecting base 2 is fixedly connected with the external machining arm through bolts.

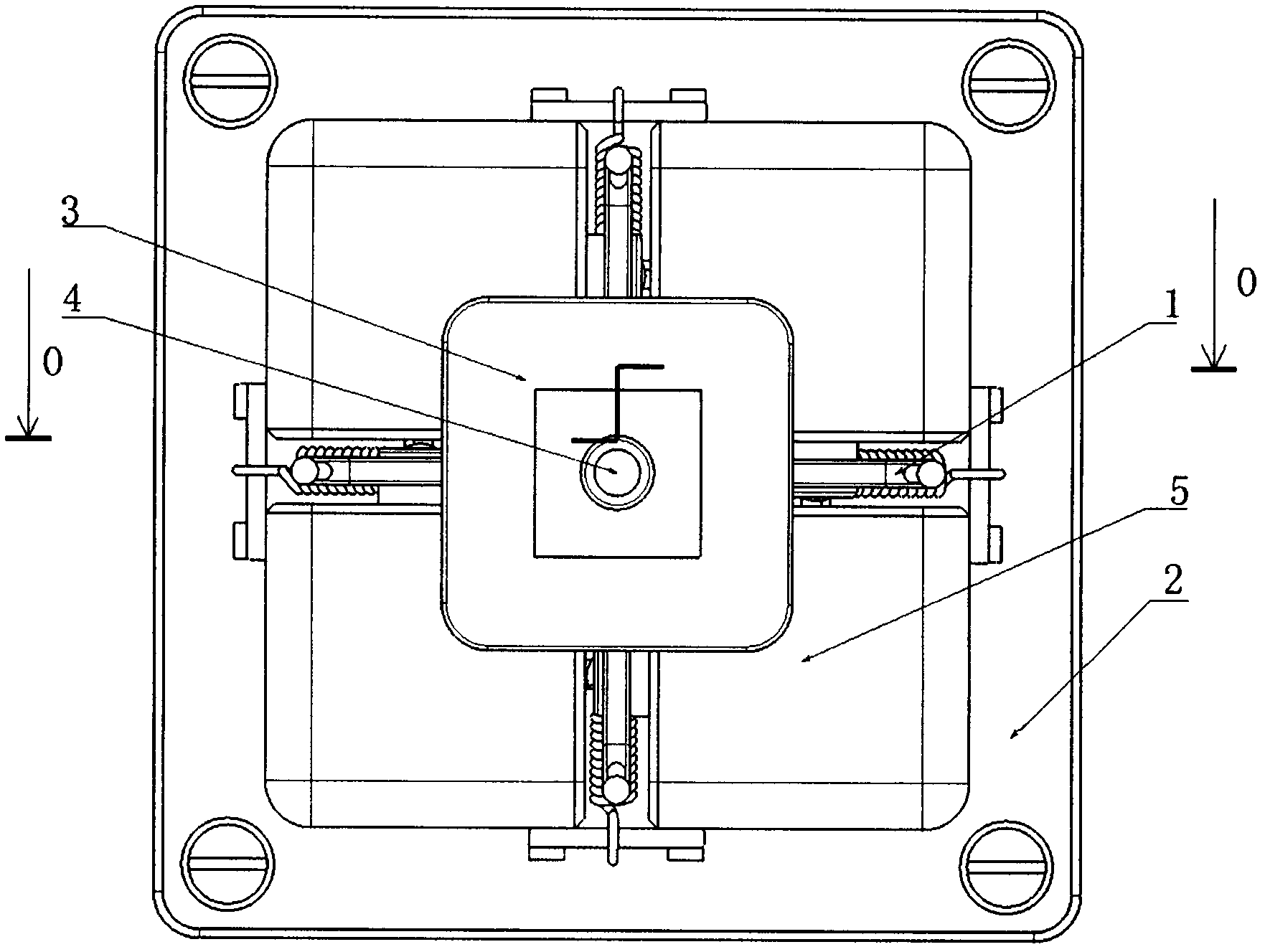

[0035] Refer to attached figure 2 , attached ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com