Nail cabin assembly of linear cutting anastomat and anastomat applying nail cabin assembly

A linear cutting and stapler technology, which is applied in the field of staplers and linear cutting stapler staple cartridge components, can solve problems affecting surgical operations, cutter blade curling, and cutter exposure, etc., to ensure cutting quality, simple overall structure, Avoid the effect of the blade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

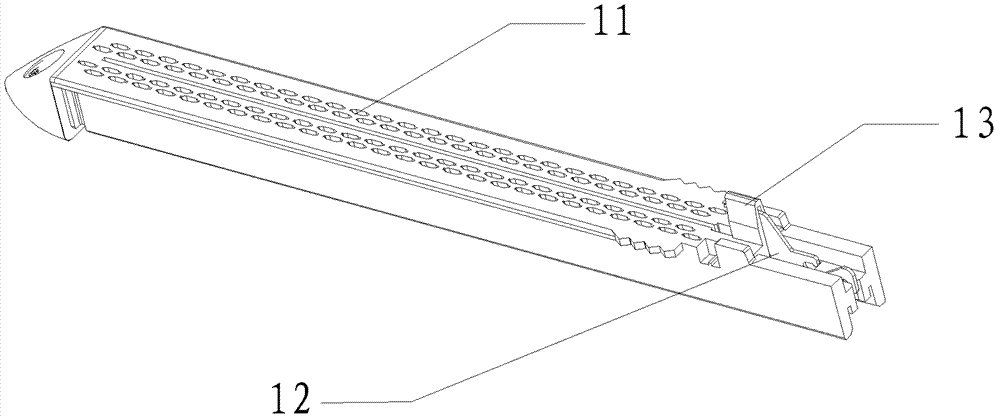

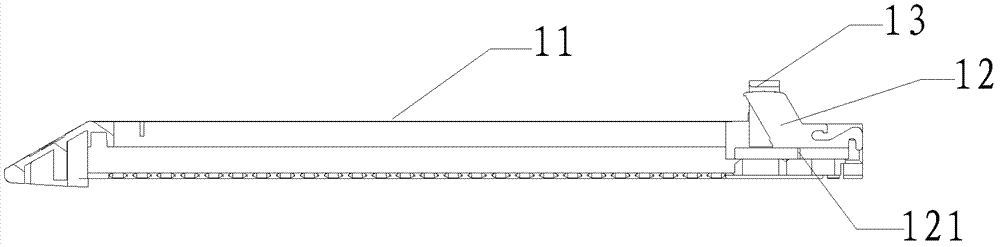

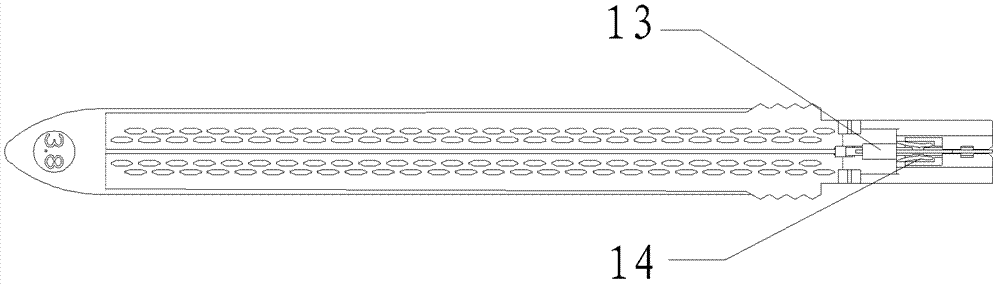

[0024] see Figure 1-4 As shown, a linear cutting stapler staple cartridge assembly 1 of the present invention includes a staple cartridge 11, a cutting knife 12, a cutting knife protective cap 13, and a knife guard shrapnel 14, and the cutting knife 12 is installed in the guide groove at the tail of the knife groove of the nail cartridge 11. Among them, the cutting knife protective cap 13 is fixed on the tail of the staple bin 11 above the cutting knife 12, and the shrapnel shrapnel 14 is fixed on the side of the cutting knife 12 inside the tail of the nail bin 11 and elastically clamped.

[0025] Wherein, as shown in the figure, the knife guard shrapnel 14 is preferably two pieces, which are in an outwardly curved arc shape, and are arranged symmetrically on both sides of the cutting knife 12 . And small-sized vertical grooves 121 can be set on both sides of the cutting knife 12, and vertical ribs 141 corresponding to the vertical grooves 121 are set on the knife guard shrap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com