Method for making dried salted peanut

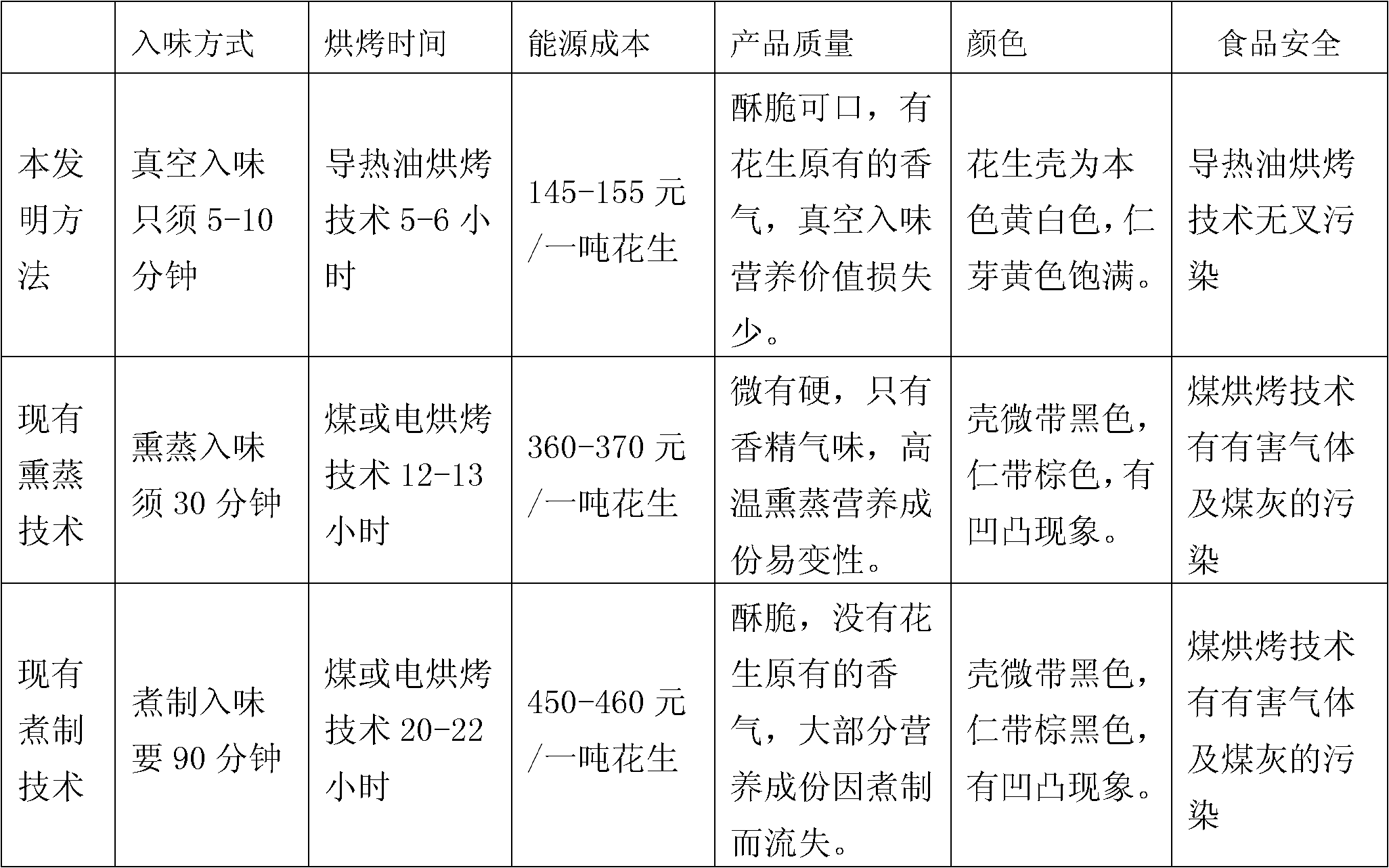

A production method and technology of salted and dried peanuts are applied in the field of food processing, which can solve the problems of nutrient loss, large cross-contamination of products, waste of social resources, etc., and achieve the effects of easy control of conditions, high nutritional value and long aftertaste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1, the making of original taste salty dried peanut

[0021] Select four red peanuts with full grains, bright red color and uniform size, pour them into a peanut washing machine, add drinking water twice the weight of the peanuts to clean the impurities and dust on the peanut shells; then remove the peanuts from the water and drain them After the surface moisture is transferred to the vacuum flavoring container, the container is sealed, and the vacuum pump is turned on to evacuate it to generate a negative pressure of minus 0.08MPa. Keep the pressure for 5 minutes. water 96%, and edible salt 4%) inhale the inside of the peanut, the weight ratio of the ingredient solution to the peanut is 1:1; then rinse the surface of the peanut shell with drinking water for 15-30 seconds to remove the ingredient solution on the surface of the peanut shell ;Finally drain the moisture on the surface of the peanuts and move them to the open cylindrical oven, and use the suction ...

Embodiment 2

[0022] Example 2, the production of creamy salty dried peanuts

[0023] Select four red peanuts with full grains, bright red color and uniform size, pour them into a peanut washing machine, add drinking water 2.5 times the weight of the peanuts to clean the impurities and dust on the peanut shells; then remove the peanuts from the water and drain them After the surface moisture is transferred to the vacuum flavoring container, the container is sealed, and the vacuum pump is turned on to evacuate it to generate a negative pressure of minus 0.085 MPa. Keep the pressure for 8 minutes. During this time, the ingredient solution (drinking water 95%, edible salt 4.8%, cyclamate 0.05%, saccharin sodium 0.05%, and butter powder 0.1%) inhaled into the peanut kernel, the weight ratio of the ingredient solution to the peanut is 1.5:1; then rinse with drinking water to taste surface of the peanuts after 15-30 seconds to remove the ingredient solution on the surface of the peanut shells; fi...

Embodiment 3

[0024] Embodiment 3, the making of green tea flavor salty dry peanut

[0025] Select four red peanuts with full grains, bright red color and uniform size, pour them into a peanut washing machine, add drinking water 3 times the weight of the peanuts to clean the impurities and dust on the peanut shells; then remove the peanuts from the water and drain them After the surface moisture is transferred to the vacuum flavoring container, the container is sealed, and the vacuum pump is turned on to evacuate it to generate a negative pressure of minus 0.09MPa. Keep the pressure for 10 minutes. water 95%, edible salt 4.8%, cyclamate 0.05%, saccharin sodium 0.05%, and green tea powder 0.1%) inhaled inside the peanut, the weight ratio of the ingredient solution to the peanut is 2:1; then rinse with drinking water after taste Peanut surface for 15-30 seconds to remove the ingredient solution on the surface of the peanut shell; finally, drain the moisture on the surface of the peanut and mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com