Portable working machine

A working machine, portable technology, applied in the field of shock absorbing mechanism, can solve problems such as trouble

Active Publication Date: 2012-05-02

HITACHI KOKI CO LTD

View PDF7 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Therefore, two different types of tools need to b

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

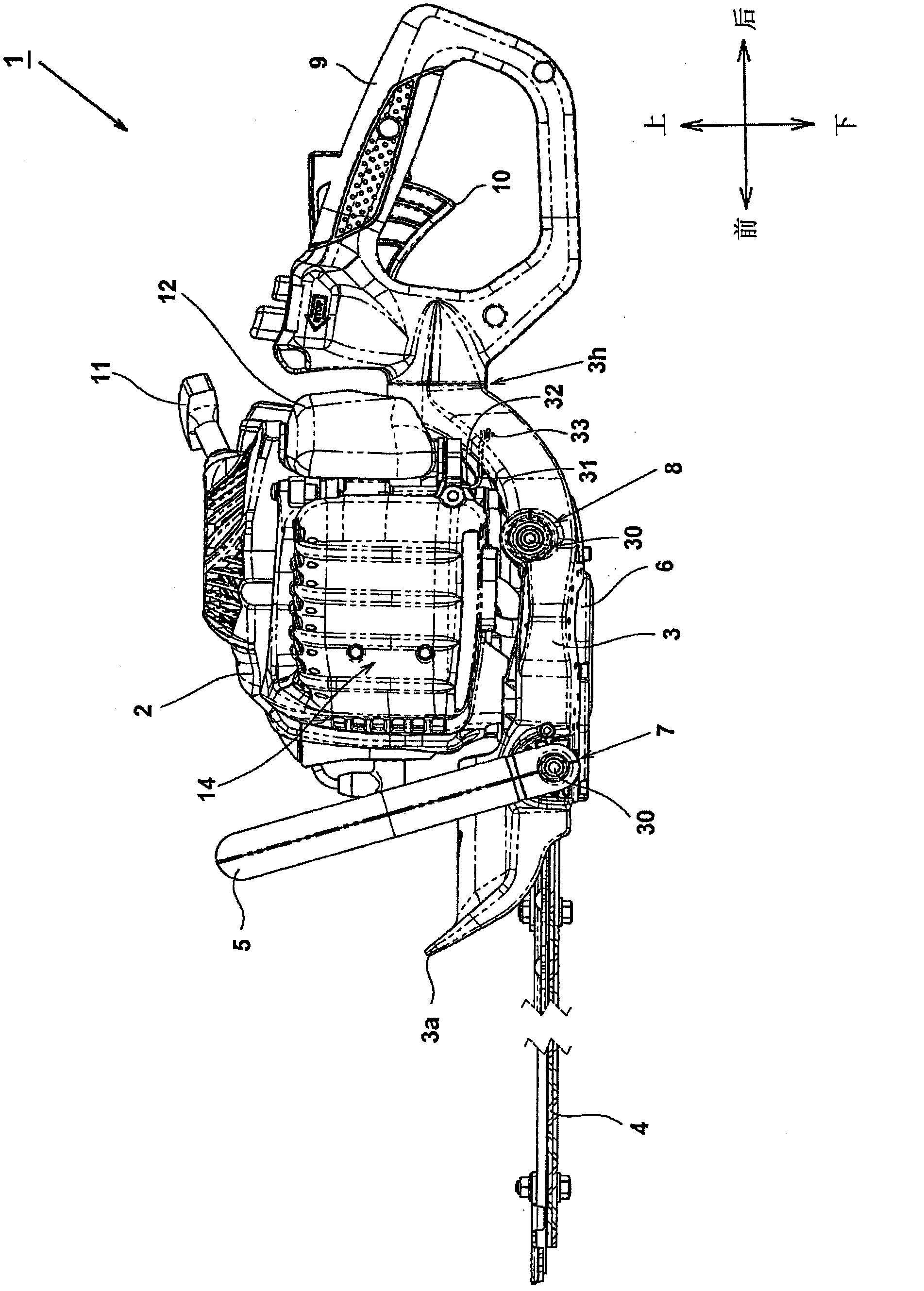

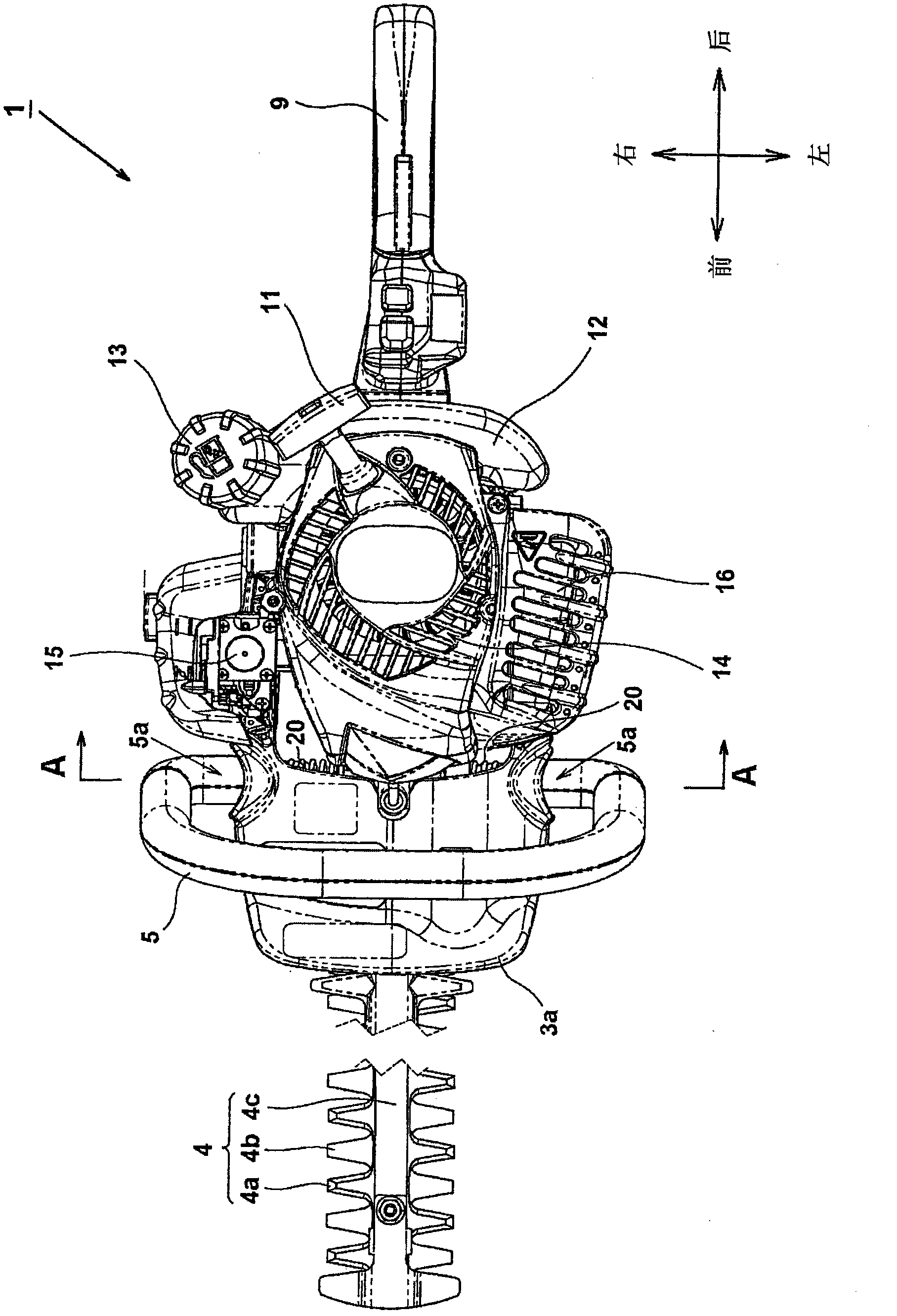

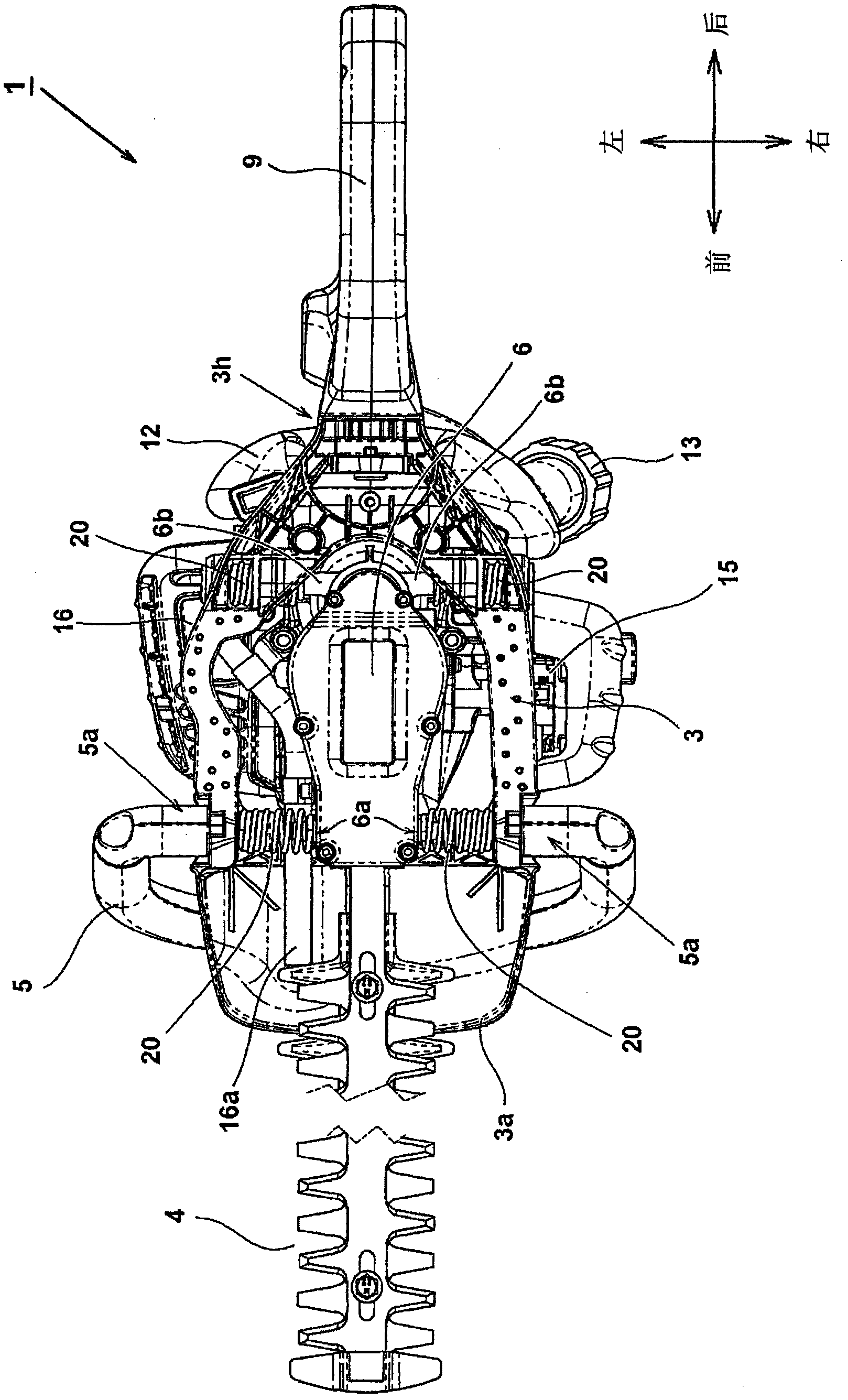

A portable working machine comprising: an engine; a frame which holds the engine; front handle and a rear handle which are provided to the frame; and a power conversion unit for transmitting an output from the engine to drive a working tool, wherein the engine, the power conversion unit and the working tool being held by the frame via an elastic member, and wherein the front handle and the elastic member are disposed so that an axis passing through a center of an attachment portion of the front handle and an axis passing through a center of an attachment portion of the elastic member substantially coincide with each other.

Description

[0001] Cross References to Related Applications [0002] This application claims priority from Japanese Patent Application No. 2010-218678 filed on September 29, 2010, the entire contents of which are incorporated herein by reference. technical field [0003] The present invention relates to a shock absorber mechanism in a portable work machine, and more particularly, to a portable work machine in which shock absorber parts and a power unit can be easily fixed. Background technique [0004] In portable work machines such as hedge trimmers (hedge trimmers), engines are widely used as power sources. Engines are advantageous in that, despite their small size and light weight, they are capable of obtaining a large output; and, with fuel supplied, they are capable of continuous operation for many hours. However, in an engine, a piston reciprocates in a cylinder and creates an explosion when the air-fuel mixture burns. Therefore, the disadvantage of an engine is that it generate...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): A01G3/053

CPCB25B5/006A01G3/053B25F5/006

Inventor 田村福志挂札晋一

Owner HITACHI KOKI CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com