Special manual air inlet valve for device in bearing water storage equipment

A technology for air intake valves and equipment, which is applied to valve devices, mechanical equipment, valves for inflation, etc., and can solve problems such as water cut-off and automatic water discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

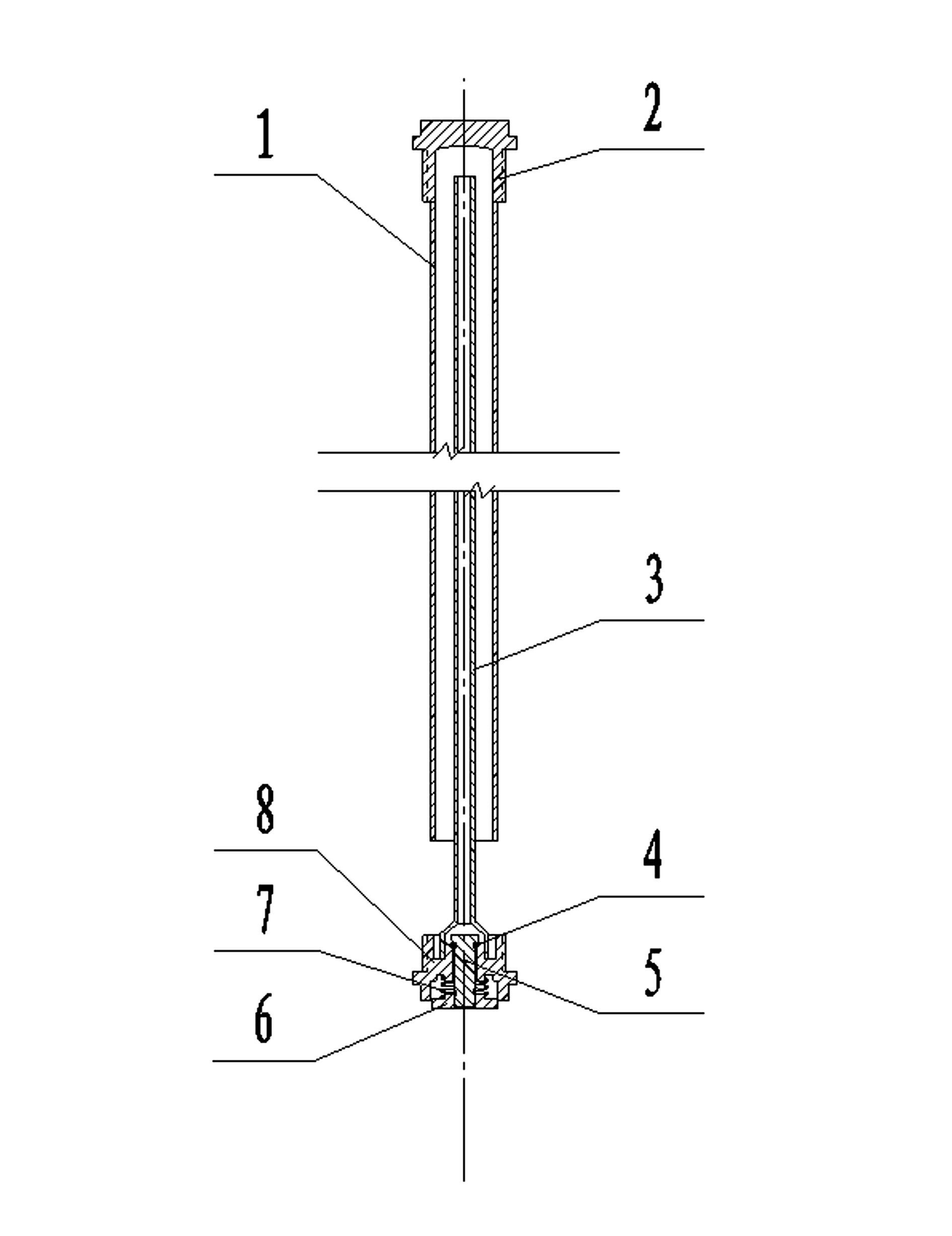

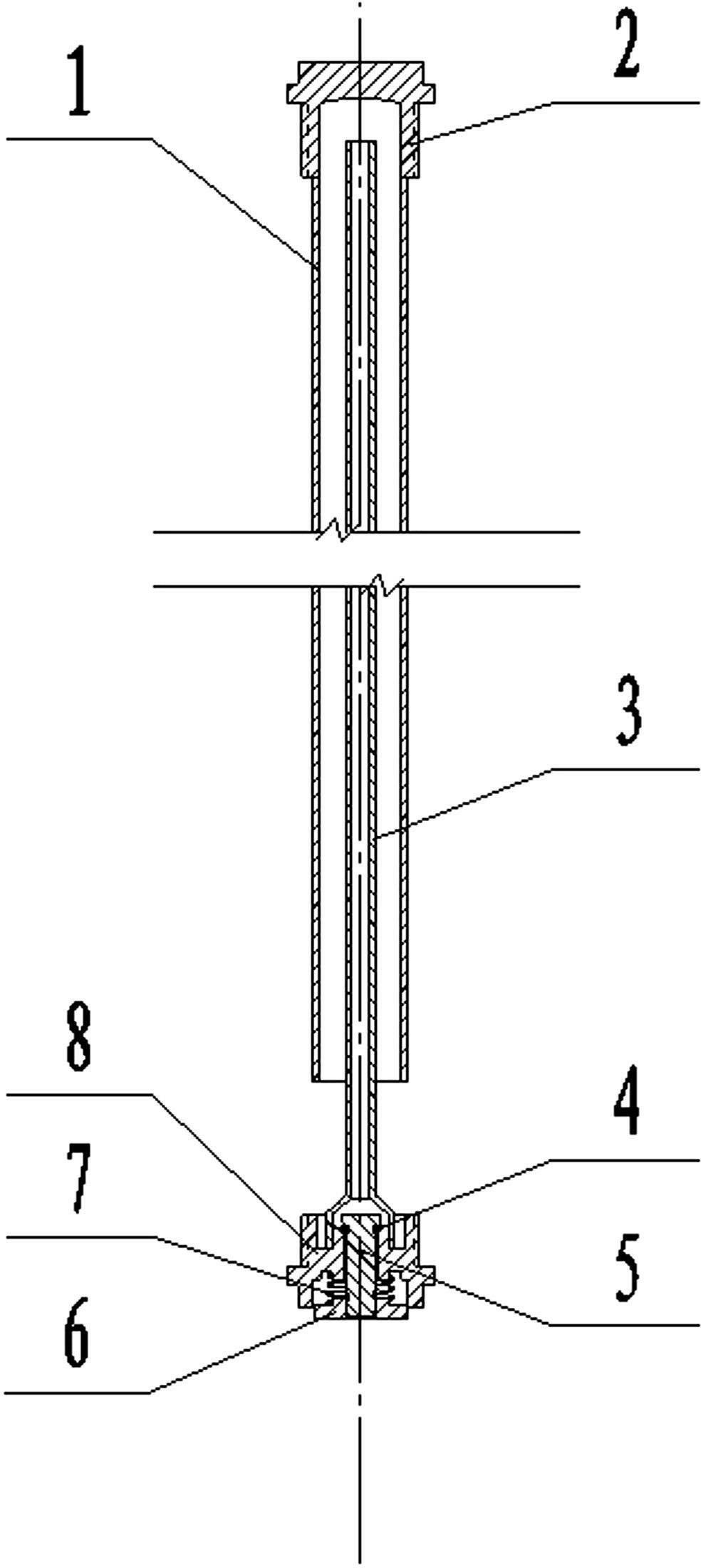

[0011] A special manual air intake valve installed in a pressurized water storage device, including an air collection pipe 1, an air collection pipe joint 2, an air intake pipe 3, a sealing ring 4, a push rod 5, a push button 6, a compression spring 7, and a valve seat 8. Among them, the lower end of the air collecting pipe 1 is provided with an opening; the air collecting pipe joint 2 is sealed and connected to the upper end of the air collecting pipe 1; the upper end of the air inlet pipe 3 extends into the inner cavity of the air collecting pipe 1, and the upper end of the air inlet pipe 3 is close to the lower end surface of the air collecting pipe joint 2; The lower end of the intake pipe 3 extends out of the air collecting pipe 1, and the lower end of the intake pipe 3 is sealed and connected with the middle hole of the valve seat 8; the push rod 5 runs through the middle hole of the valve seat 8; the upper side of the push rod 5 is processed with grooves , the sealing ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com