Hydraulic system for preventing hydraulic circuit from being influenced by deadweight of part

A hydraulic circuit and hydraulic system technology, applied in the field of hydraulic systems, can solve problems such as lack of safety, high maintenance costs, poor resistance adjustability, etc., and achieve the effect of good adjustability and low maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

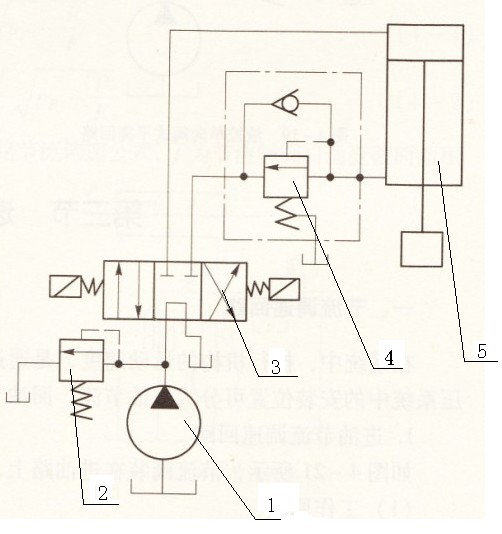

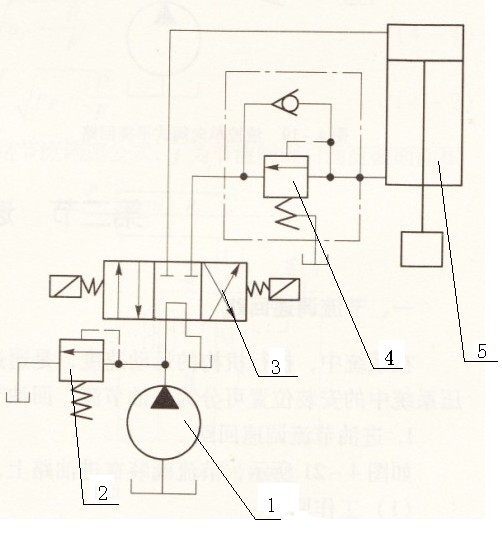

[0007] Below in conjunction with accompanying drawing, further illustrate the present invention.

[0008] Such as figure 1 The structural representation of the present invention shown, it comprises oil pump 1, overflow valve 2, electromagnetic valve 3, sequence valve 4 and hydraulic cylinder 5, the intermediate place of the output end of described oil pump 1 and the input end of electromagnetic valve 3 is provided with overflow Valve 2, the output end of electromagnetic valve 3 is connected with the input end of sequence valve 4, the output end of sequence valve 4 is connected with one end of hydraulic cylinder 5, and the other end of hydraulic cylinder 5 is connected with electromagnetic valve 3.

[0009] Such as figure 1 As shown, the adjustment pressure of the sequence valve 4 should be slightly greater than the pressure of the mass of the working parts in the stroke of the lower cavity of the hydraulic unit 5. When the self-weight is large, the pressure of the sequence va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com