Energy converter

A technology of energy converters and barriers, applied in the direction of machines/engines, mechanical equipment, mechanisms that generate mechanical power, etc., can solve the problem of converting into mechanical energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

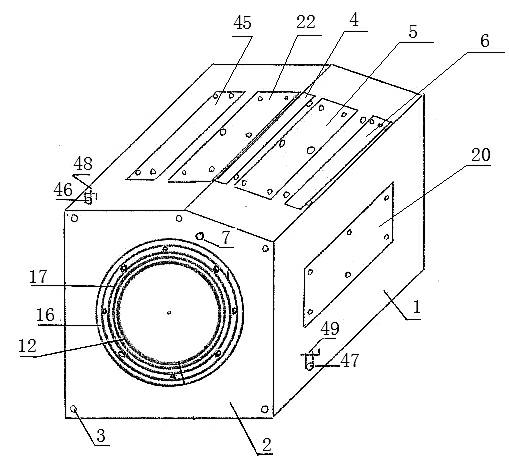

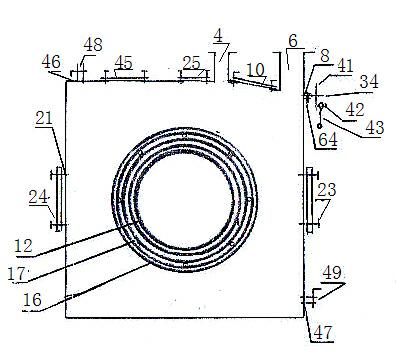

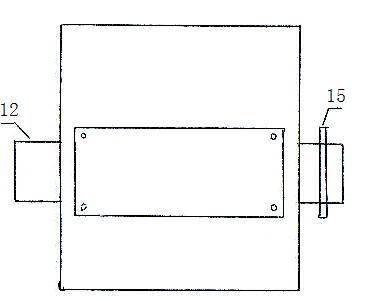

[0040] Such as Figure 1-13 As shown, the energy converter is provided with a housing 1, a housing cover 2 is provided at one end of the housing 1, and a plurality of screw mounting holes are provided at the junction of the housing cover 2 and the housing 1, and the housing cover 2 is installed with screws 3. On the shell 1, a shell cavity is formed. A sealing ring is installed at the junction of the shell cover 2 and the shell 1. A hollow shaft perforation is provided in the center of the shell cover 2 and the center of the other end of the shell 1. The hollow shaft perforates the wall A large bearing installation groove 16 is provided on the outer hole wall of the center, a large bearing 17 is installed in the large bearing installation groove 16, a hollow shaft 12 is installed on the inner hole of the large bearing 17, and the center of the upper shell vertically upwards from the center of the shell cavity is slightly offset The shell on the right is provided with an upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com