Rotary vertical shaft sealing device of forward excavator

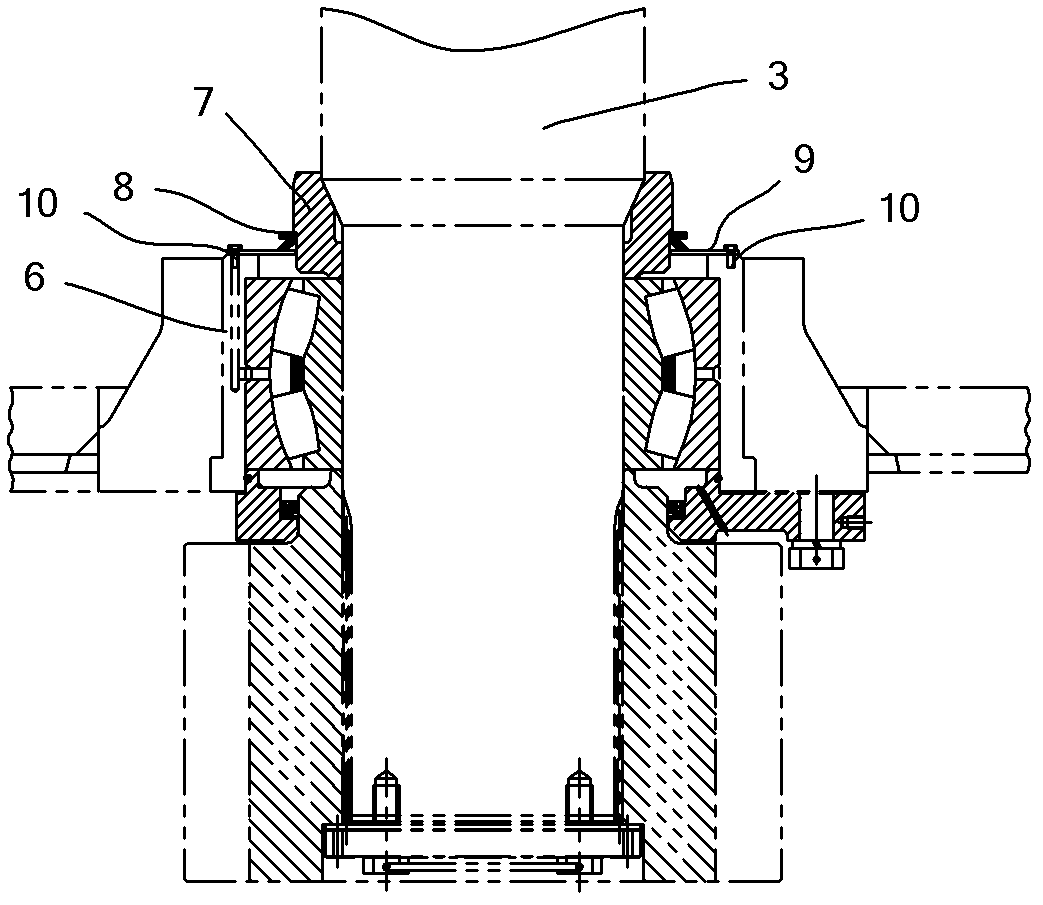

A front shovel excavator and sealing device technology, which is applied to earth moving machines/shovels, construction, etc., can solve the difficulty of installing the annular baffle 9 and the oil seal 8, improve labor intensity and operating cost, and troublesome to replace the oil seal 8, etc. problems, to achieve the effect of reducing unsafe factors, reducing labor, and adjusting process safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Typical embodiments embodying the features and advantages of the present invention will be described in detail in the following description. It should be understood that the present invention is capable of various changes in different embodiments without departing from the scope of the present invention, and that the description and drawings therein are illustrative in nature and not limiting. this invention.

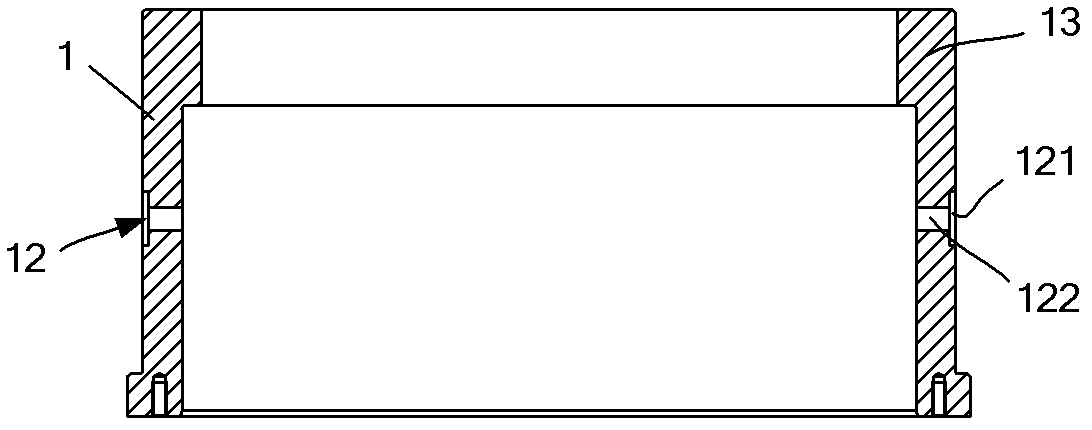

[0026] Such as figure 2 As shown, the present invention includes a bearing sleeve 1 and a positioning sleeve 2 . Wherein, the bearing sleeve 1 is used to cooperate with the outer ring of the fixed bearing 4 , and the positioning sleeve 2 is used to fix the inner ring of the bearing 4 .

[0027] Such as image 3 As shown, the outer ring of the bearing 4 is installed in the bearing sleeve 1 to prevent the axial movement of the bearing 4, and the bearing sleeve 1 is installed in the rotary vertical shaft bracket 5. The setting of the bearing sleeve 1 facilitate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com