Reinforced combined arch ring for arch bridge

A reinforced, arch ring technology, applied in the direction of bridge reinforcement, arch bridges, bridges, etc., can solve the problems of difficulty in pre-stress loading operation, difficulty in pre-stressing, and inconvenience, and improve the distribution of constant load internal force, transportation and installation. Quick and easy-to-build effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

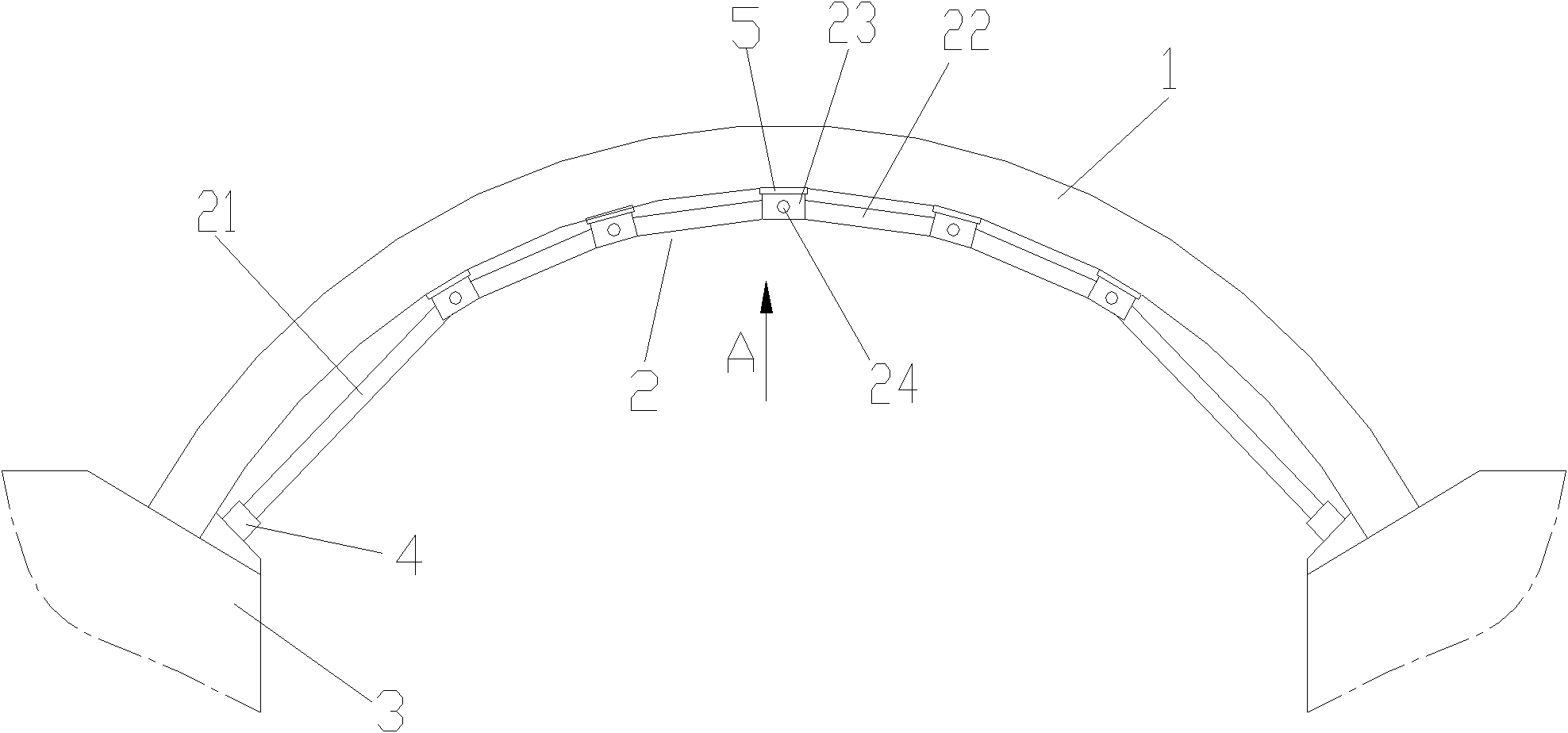

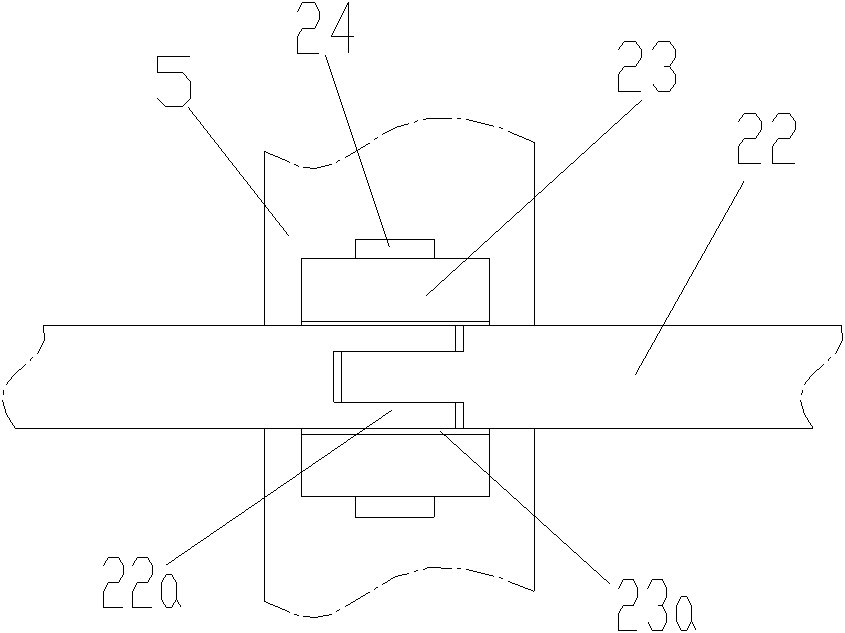

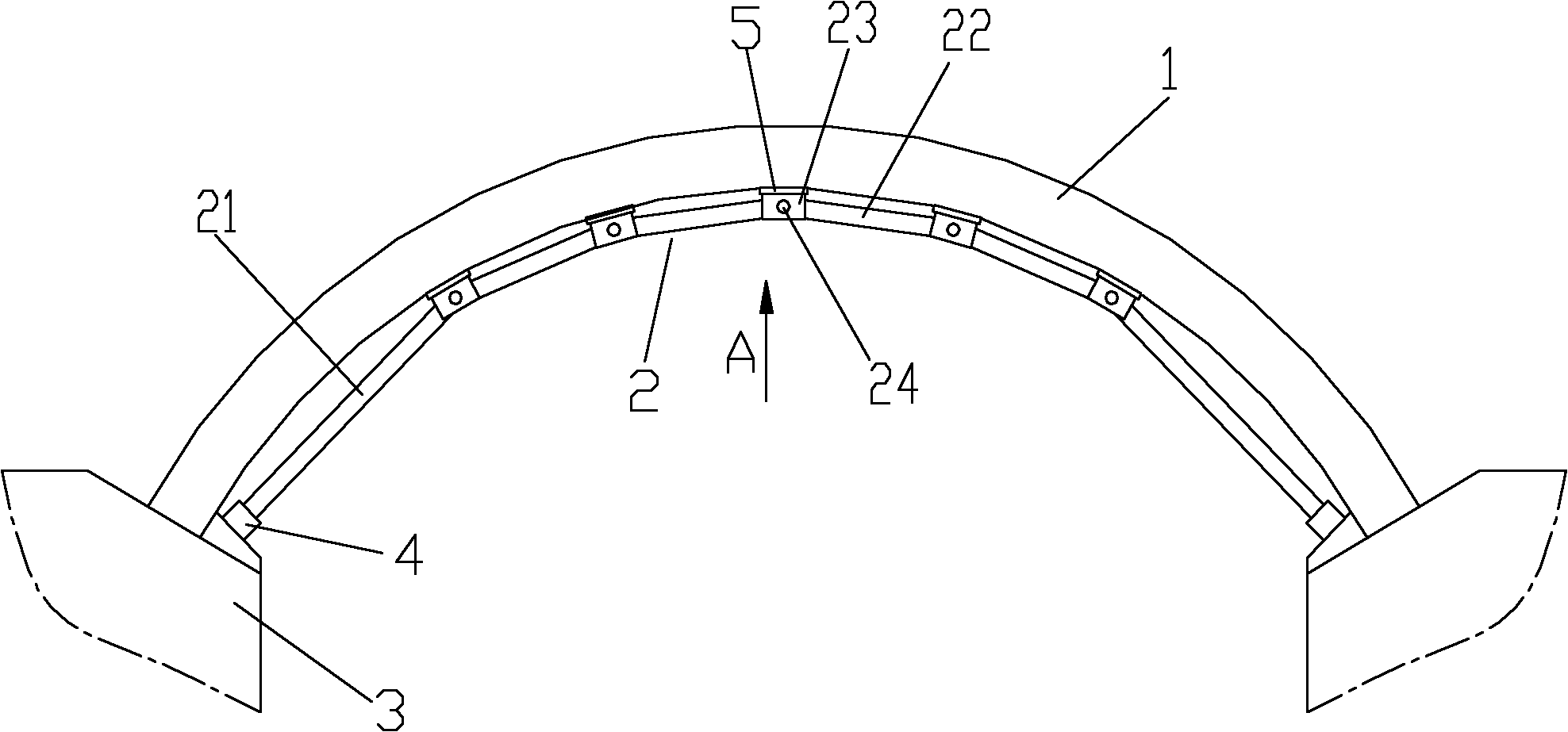

[0021] figure 1 It is a schematic diagram of the structure of the present invention, figure 2 for figure 1 View along the direction A, as shown in the figure: the arch bridge reinforced composite arch ring of this embodiment includes a main arch ring 1 and a broken-line hinged arch 2 located at the lower part of the main arch ring 1, and the broken-line hinged arch 2 is sequentially hinged. The load-bearing rods of adjacent hinges (including the load-bearing rods 22 in the middle of the broken-line hinged arch and the load-bearing rods 21 positioned at the two ends of the broken-line hinged arch) are hinged to a load-bearing member 23, such as As shown in the figure, the broken-line hinged arch 2 is formed by hinged end-to-end load-bearing rods; wherein the load-bearing rods 21 located at both ends of the broken-line hinged arch are applied with precompressive stress. The stress is transmitted sequentially and runs through the entire hinged arch; the load-bearing member 23 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com