Synthetic base drilling fluid

A drilling fluid and synthetic-based technology, applied in the direction of drilling composition, chemical instruments and methods, etc., can solve the problems of barite settlement, low drilling fluid viscosity, formation fracture, etc., and achieve good high-temperature and high-pressure filtration loss, Good biodegradability, the effect of wide acid-base conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

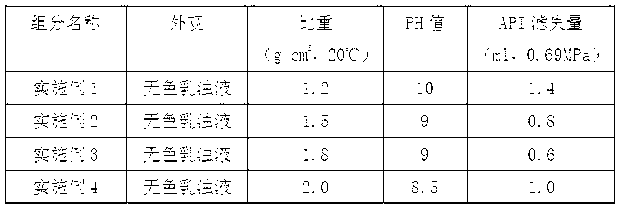

Examples

Embodiment 1

[0017] According to the weight ratio relationship, take 1 part of limonene, 0.5 parts of dipentene, 5 parts of ethylene glycol monobutyl ether, 1 part of alkyl glycoside, 1.95 parts of alcohol ether carboxylate, 10 parts of white oil and 1.25 parts of simethicone , mix the above raw materials to obtain a base fluid; add 1 part of calcium hydroxide, 9.43 parts of barite powder and 2.3 parts of water to the above base fluid, and then stir evenly to obtain an emulsion that is the drilling fluid.

Embodiment 2

[0019] According to the weight ratio relationship, take 1 part of limonene, 0.75 parts of dipentene, 3 parts of ethylene glycol monobutyl ether, 5 parts of alkyl glycosides, 1.5 parts of alcohol ether carboxylate, 1 part of white oil and 3 parts of simethicone , mix the above raw materials to obtain a base fluid; add 0.45 parts of calcium hydroxide, 15.25 parts of barite powder and 3.05 parts of water to the above base fluid, and then stir evenly to obtain an emulsion that is the drilling fluid.

Embodiment 3

[0021] According to the weight ratio relationship, take 1 part of limonene, 1 part of dipentene, 2.5 parts of ethylene glycol monobutyl ether, 10 parts of alkyl glycosides, 3 parts of alcohol ether carboxylate, 5 parts of white oil and 1.5 parts of simethicone , mix the above raw materials to obtain a base fluid; add 0.24 parts of calcium hydroxide, 39.99 parts of barite powder and 8 parts of water to the above base fluid, and then stir evenly to obtain an emulsion that is the drilling fluid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com